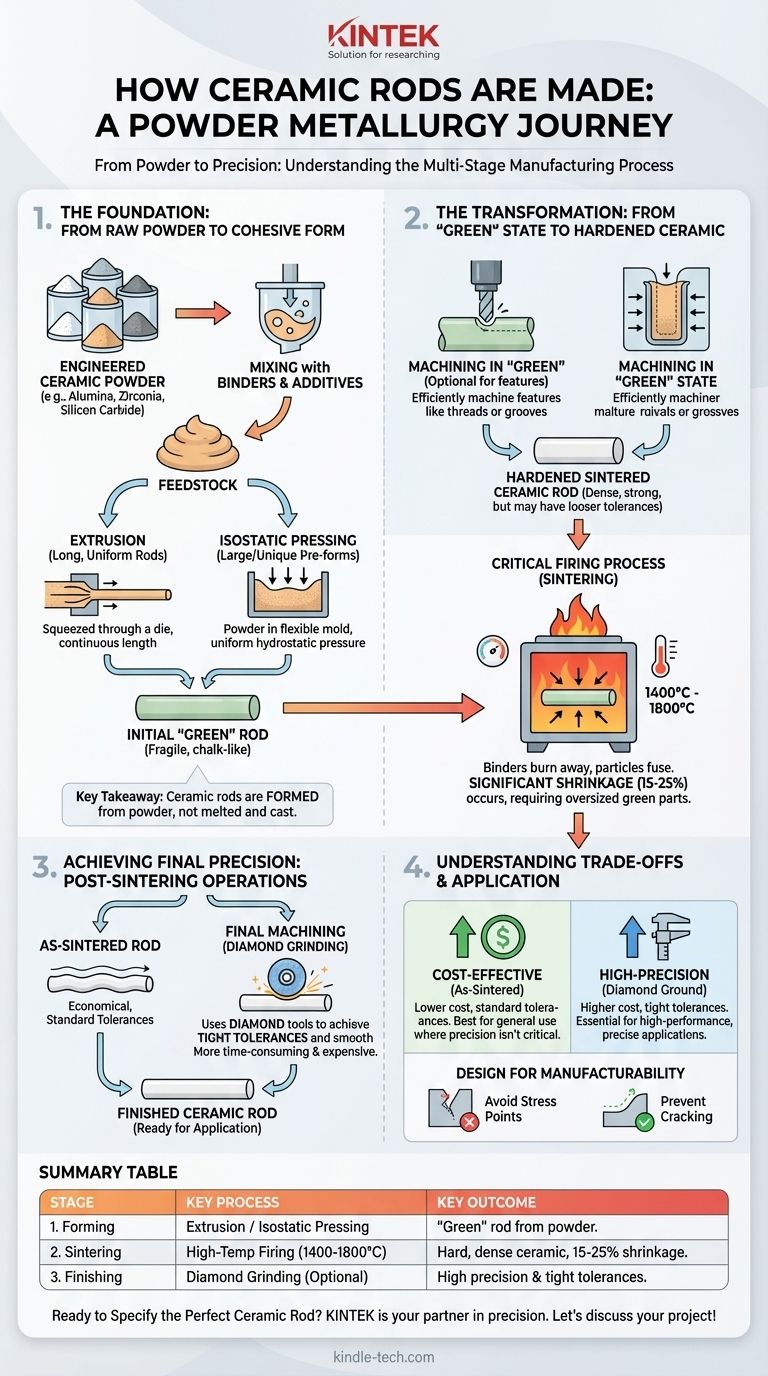

At its core, manufacturing a ceramic rod is a multi-stage process of powder metallurgy. It begins by mixing fine ceramic powders with binders to form a workable mass, which is then shaped, heated at extreme temperatures in a process called sintering to fuse the particles, and often finished with precision grinding to meet final specifications.

The key takeaway is that ceramic rods are not melted and cast like metal; they are formed from a powder and fired. This fundamental difference explains their unique properties, including high-temperature stability, extreme hardness, inherent brittleness, and the manufacturing challenges related to shrinkage and dimensional tolerance.

The Foundation: From Raw Powder to Cohesive Form

The final properties of a ceramic rod are determined long before it ever enters a furnace. The process begins with the careful selection and preparation of raw materials.

Starting with the Right Ingredients

The process starts with a highly pure, engineered ceramic powder, such as alumina (aluminum oxide), zirconia (zirconium dioxide), or silicon carbide. The particle size, distribution, and purity of this initial powder are critical variables that directly influence the density, strength, and final quality of the rod.

Creating a Workable Mass

The dry powder is mixed with various organic additives, including a binder to hold the particles together, a plasticizer for flexibility, and other agents. This transforms the powder into a uniform, dough-like consistency known as a feedstock, which is essential for the forming process.

The Two Primary Forming Methods

Once the feedstock is prepared, it must be shaped into its initial "rod" form. The two most common methods are extrusion and isostatic pressing.

- Extrusion: For producing long rods with a uniform cross-section, extrusion is the most efficient method. The feedstock is forced through a die orifice, similar to squeezing toothpaste from a tube, to create a continuous length of the desired shape.

- Isostatic Pressing: For larger diameter rods or unique pre-forms, Cold Isostatic Pressing (CIP) is used. The ceramic powder (with minimal binders) is placed in a flexible mold, which is then subjected to immense, uniform hydrostatic pressure. This compacts the powder into a solid, dense pre-form.

The Transformation: From "Green" State to Hardened Ceramic

The formed rod is not yet a true ceramic. It exists in a fragile, chalk-like condition known as the "green" state. The next steps transform this green part into a hard, dense, technical ceramic.

Machining in the "Green" State

If the final rod requires features like threads, steps, or grooves, it is far more efficient and economical to machine them while the part is still in its soft, green state. This is done using conventional tools, though great care is required due to the material's fragile nature.

The Critical Firing Process (Sintering)

This is the most crucial step. The green part is placed in a high-temperature furnace and heated to a precise temperature, typically between 1400°C and 1800°C. This temperature is below the material's melting point.

During sintering, the binders burn away, and the ceramic particles fuse together at their contact points. The part densifies, eliminating porosity and transforming into an extremely hard and strong component.

The Challenge of Shrinkage

A defining characteristic of sintering is shrinkage. As the part densifies, it shrinks significantly and uniformly—often by 15% to 25%. Engineers must precisely calculate and compensate for this shrinkage by making the green part oversized. Unpredictable shrinkage is a primary reason why as-sintered parts have looser dimensional tolerances.

Achieving Final Precision: Post-Sintering Operations

While sintering creates the desired hardness and thermal properties, it rarely produces a part with perfect dimensional accuracy.

Why Final Machining is Necessary

Minor warping or dimensional variations from the sintering process mean that as-fired rods may not meet the tight tolerances required for many technical applications. To achieve high precision, a final machining stage is necessary.

The Art of Diamond Grinding

Once fired, the ceramic is one of the hardest materials available. It can only be effectively machined by an even harder material: diamond.

Post-sintering machining involves slow, precise diamond grinding. This process can achieve extremely tight tolerances and very smooth surface finishes, but it is significantly more time-consuming and expensive than green machining.

Understanding the Trade-offs

The manufacturing process directly informs the cost and performance trade-offs you must consider when specifying a ceramic rod.

Cost vs. Precision

There is a direct and steep relationship between tolerance and cost. An "as-sintered" rod with standard tolerances is the most economical option. Requiring post-sintering diamond grinding to achieve a tight tolerance can easily multiply the final part cost.

Inherent Brittleness

The powder-based process can leave behind microscopic pores or grain boundaries within the material. These tiny, unavoidable imperfections act as stress concentration points, which is the fundamental reason why ceramics are brittle and fail suddenly under tensile or impact loads, unlike ductile metals.

Design for Manufacturability (DFM)

Understanding this process allows for better design. Avoid sharp internal corners, which create stress points. Design with gradual changes in thickness to prevent cracking during sintering. Most importantly, specify tight tolerances only where they are functionally required to control costs.

How to Apply This to Your Project

Your choice of manufacturing specifications should be driven entirely by your application's requirements.

- If your primary focus is cost-effectiveness for general use: Specify an extruded, "as-sintered" rod and design your assembly to accommodate standard dimensional tolerances.

- If your primary focus is high precision and tight tolerances: You must specify post-sintering diamond grinding, and your budget must reflect the significant increase in cost and lead time.

- If your primary focus is complex geometry (threads, grooves): Ensure these features are specified for "green machining" to minimize cost, but work with the manufacturer to properly account for sintering shrinkage in your design.

By understanding how a ceramic rod is made, you can make smarter design decisions, write more effective specifications, and better predict the performance of your final component.

Summary Table:

| Manufacturing Stage | Key Process | Key Outcome |

|---|---|---|

| 1. Forming | Extrusion or Isostatic Pressing | Creates the initial "green" rod shape from powder feedstock. |

| 2. Sintering | High-temperature firing (1400°C - 1800°C) | Fuses particles, creating a hard, dense ceramic (15-25% shrinkage). |

| 3. Finishing | Diamond Grinding (if required) | Achieves final, high-precision dimensions and tight tolerances. |

| Key Trade-off | As-Sintered vs. Ground | Cost-Effective vs. High-Precision |

Ready to Specify the Perfect Ceramic Rod for Your Application?

Understanding the manufacturing process is the first step to selecting the right component. Whether you need a cost-effective as-sintered rod or a high-precision ground component, KINTEK is your partner in precision.

We specialize in providing lab equipment and consumables, including high-performance ceramic components tailored to your exact needs. Our experts can help you navigate the trade-offs between cost and precision to ensure optimal performance for your specific application—from thermal management systems to high-wear environments.

Let's discuss your project requirements and find the most efficient manufacturing solution.

Contact our ceramic experts today for a consultation!

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

People Also Ask

- What are some of the important characteristics of sintered ceramics? Achieve High-Performance Material Properties

- What is the primary purpose of using zirconia coatings in W-Cu infiltration? Ensure Dense, Void-Free Composites

- What is the maximum temperature for ceramics? Find the Right Material for Your High-Temp Application

- What are the process advantages of selecting an alumina plate for CuO nanofilm synthesis? Achieve Superior Purity

- Where are ceramics used in the body? Key Applications in Orthopedics, Dentistry & Bone Repair

- What determines the strength of ceramics? The surprising role of microscopic flaws in brittle failure

- What are the limitations of silicon carbide? Managing Brittleness and Performance Drift

- Why are Beta-Al2O3 pellets covered with powder during sintering? Master Volatility Control for Better Ceramics