Rotary kilns are heated using two primary methods: direct heating, where the flame and combustion gases are inside the kiln with the material, and indirect heating, where the kiln is heated from the outside. The energy sources for these methods range from fossil fuels like natural gas and coal to clean electricity. The selection is determined by the specific chemical reaction or physical change required for the material being processed.

The choice between direct and indirect heating is the most critical decision in rotary kiln design. Direct heating is powerful and efficient for robust materials, while indirect heating provides the precise control and atmospheric purity essential for sensitive applications.

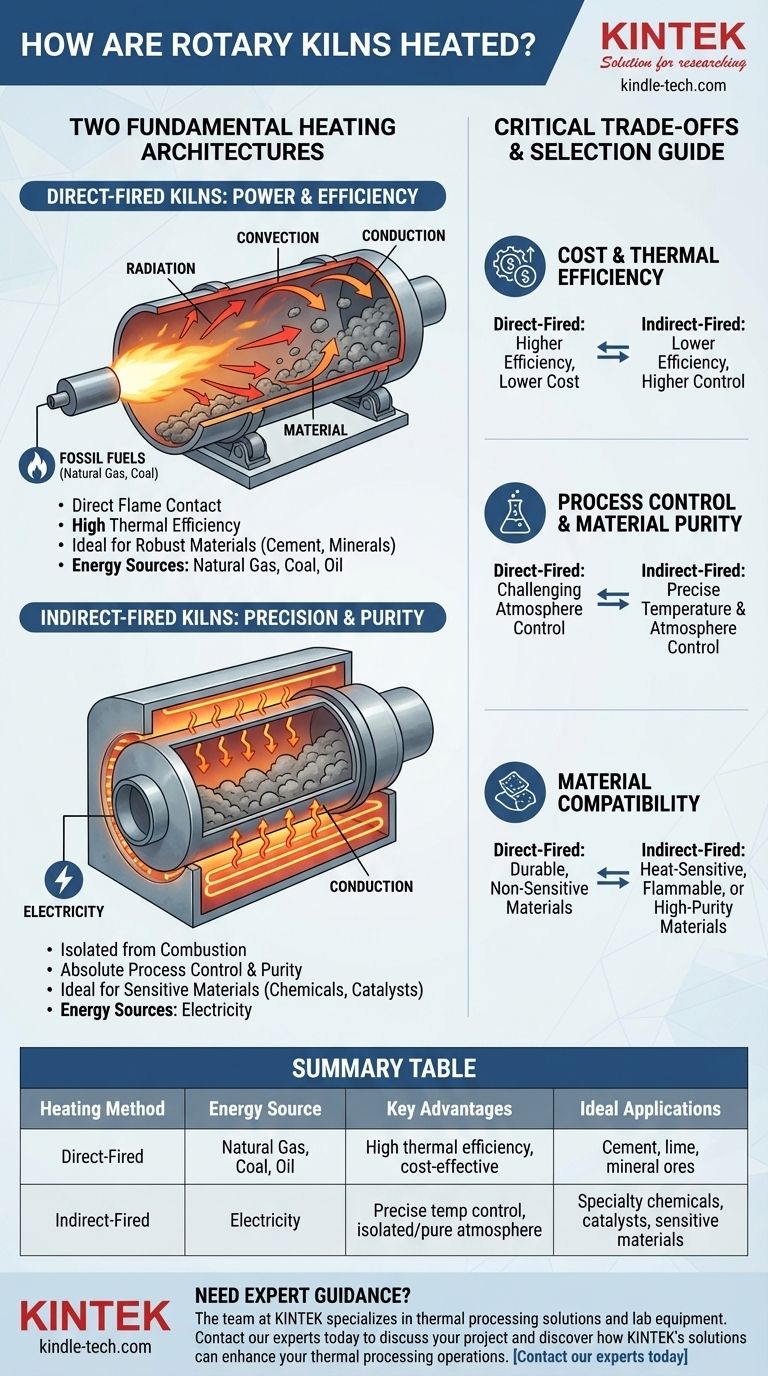

The Two Fundamental Heating Architectures

The core design of a rotary kiln dictates how heat is applied to the material. This distinction between "inside" and "outside" heating governs nearly every other aspect of the system, from fuel choice to process control.

Direct-Fired Kilns: Power and Efficiency

In a direct-fired system, a burner injects a flame directly into the rotating drum. The material tumbles through the hot combustion gases as it moves down the length of the kiln.

This method transfers heat to the material in three ways simultaneously: radiation from the flame, convection from the hot gases, and conduction from the hot refractory lining of the kiln walls.

Because the heat source is in direct contact with the material, this architecture is highly effective for high-temperature processes involving robust materials like cement, lime, and mineral ores.

Indirect-Fired Kilns: Precision and Purity

In an indirect-fired system, the rotating drum is enclosed within an external heating chamber or shell. The material inside the drum is completely isolated from the flame and combustion byproducts.

Heat is applied to the outside of the drum and conducted through the metal wall to the material inside. This method is often called an "externally heated" kiln.

The primary advantage is absolute process control. Because the internal atmosphere is sealed, it can be precisely managed—whether it needs to be inert, oxidizing, or reducing. This makes it essential for sensitive, high-purity, or reactive materials.

Understanding the Sources of Heat

The choice of heating architecture is closely linked to the energy source used. Each fuel type offers a different balance of cost, control, and compatibility.

Fossil Fuels: The Traditional Workhorse

Natural gas, fuel oil, propane, and coal are the most common energy sources for direct-fired kilns.

These fuels provide immense thermal energy at a relatively low cost, making them ideal for large-scale industrial operations that require extremely high temperatures.

Electricity: The Precision Tool

Electricity is the standard energy source for indirect-fired kilns. It powers resistive heating elements arranged in the external chamber that surrounds the rotating drum.

While often more expensive to operate, electricity provides unmatched temperature precision and uniformity. It is inherently clean, producing no combustion gases that could contaminate the final product.

Waste Heat and Alternative Fuels

Modern kiln systems often incorporate heat recovery to improve efficiency. The hot exhaust gases or discharged solids can be used to pre-heat the incoming feed material, significantly reducing overall energy consumption.

In some specialized cases, synthetic gases or other waste-derived fuels can also be used, typically in direct-fired configurations.

Critical Trade-offs: Direct vs. Indirect Heating

Your choice of heating method involves a clear set of engineering trade-offs. There is no single "best" option; there is only the best option for a specific application.

Cost and Thermal Efficiency

Direct-fired kilns are generally more thermally efficient because the heat is generated directly where it is needed. This often results in lower capital and operational costs for high-volume production.

Indirect-fired kilns lose some heat from their external shell to the surrounding environment, which can make them less energy-efficient. However, for smaller-scale or specialized processes, this is a necessary trade-off for control.

Process Control and Material Purity

Indirect heating offers far superior process control. The temperature can be regulated with high accuracy, and the isolated internal atmosphere prevents any contamination of the material.

In direct-fired systems, contact with combustion gases can introduce impurities or cause unwanted side reactions. Controlling the atmosphere is significantly more challenging.

Material Compatibility

Direct heating is suitable for durable materials that are not negatively affected by direct flame impingement or the chemical composition of flue gas.

Indirect heating is mandatory for materials that are flammable, heat-sensitive, prone to oxidation, or require an exceptionally pure final product, such as specialty chemicals, catalysts, and some food-grade products.

Selecting the Right Heating Method for Your Process

The optimal heating method is dictated entirely by your material's properties and your desired outcome. Use these guidelines to make an informed decision.

- If your primary focus is high-volume production of robust materials (like cement or minerals): A direct-fired kiln using natural gas or coal is almost always the most energy-efficient and cost-effective choice.

- If your primary focus is processing sensitive materials that require high purity or a controlled atmosphere: An electrically powered, indirect-fired kiln is the necessary solution for its precision and isolation.

- If your primary focus is balancing efficiency with moderate process control: Explore direct-fired kilns with advanced burner technology or consider systems that use waste heat recovery to pre-heat your feed material.

Understanding the fundamental difference between direct and indirect heating empowers you to select the precise tool required for your thermal processing objective.

Summary Table:

| Heating Method | Energy Source | Key Advantages | Ideal Applications |

|---|---|---|---|

| Direct-Fired | Natural Gas, Coal, Oil | High thermal efficiency, cost-effective for large volumes | Cement, lime, mineral ores |

| Indirect-Fired | Electricity | Precise temperature control, isolated/pure atmosphere | Specialty chemicals, catalysts, sensitive materials |

Need Expert Guidance for Your Rotary Kiln Application?

Choosing the right heating method is critical for your process efficiency and product quality. The team at KINTEK specializes in thermal processing solutions and lab equipment. We can help you select the ideal rotary kiln configuration—whether you require the power of direct heating or the precision of indirect heating—to meet your specific material and production goals.

Contact our experts today to discuss your project and discover how KINTEK's solutions can enhance your thermal processing operations.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the purpose of a calciner? Boost Efficiency in High-Temperature Processing

- What are the products of pyrolysis of wood? A Guide to Biochar, Bio-oil, and Syngas Yields

- What are the types of pyrolysis reactors used in industry? Choose the Right Technology for Your Product

- What are the different types of reactors in plastic pyrolysis? Choose the Right System for Your Waste

- What is the difference between calcining and roasting? A Guide to High-Temperature Processing