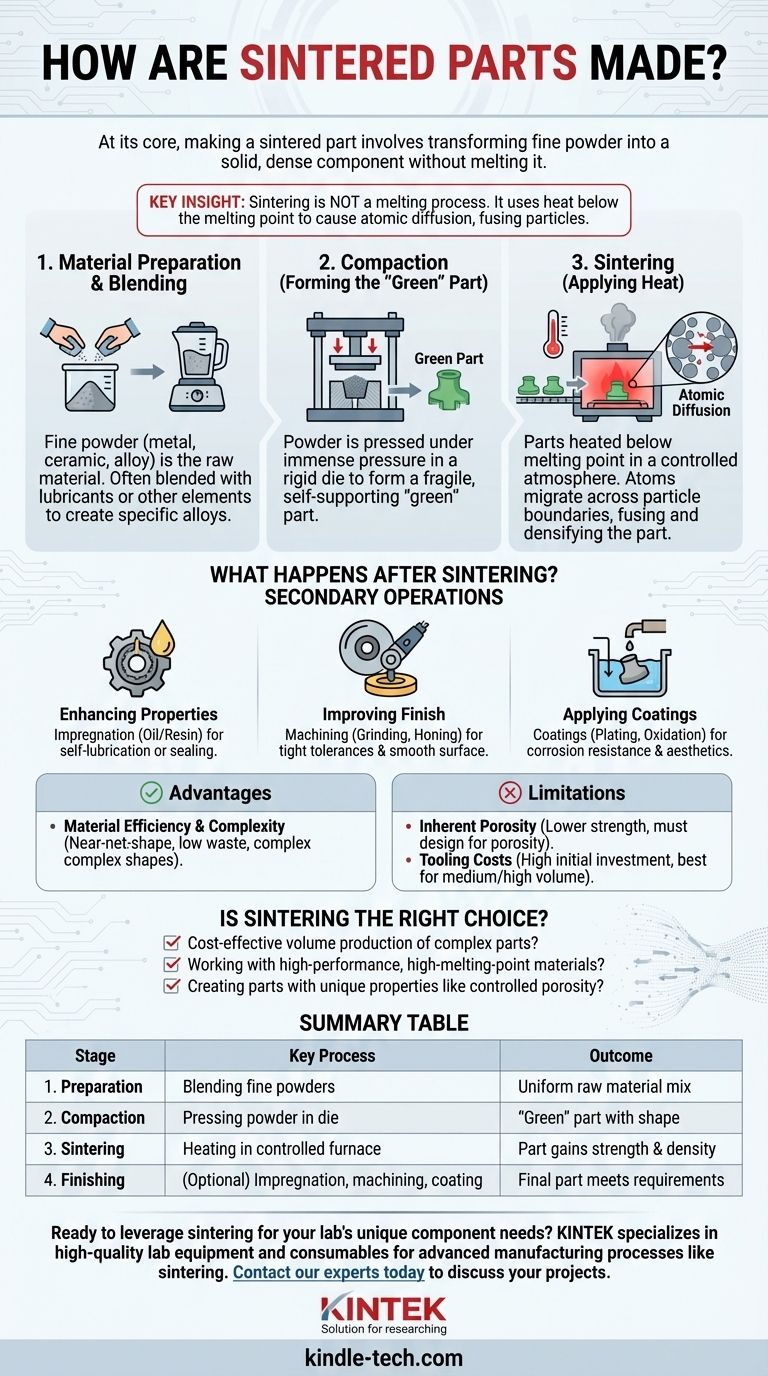

At its core, making a sintered part involves transforming fine powder into a solid, dense component without melting it. The process consists of three primary stages: blending the raw material powder, compacting it under high pressure into a preliminary shape, and then heating that shape in a controlled furnace to bond the particles together.

The crucial insight is that sintering is not a melting process. Instead, it uses heat below the material's melting point to cause atoms to diffuse across particle boundaries, fusing the powder into a strong, near-net-shape part. This makes it an ideal method for materials that are difficult to melt, cast, or machine.

The Sintering Process: A Step-by-Step Breakdown

To truly understand how sintered parts are made, we must look at each stage of the powder metallurgy (for metals) or ceramic manufacturing process.

Step 1: Material Preparation and Blending

The entire process begins with the raw material, which is always a fine powder. This could be a pure metal, a metal alloy, or a ceramic compound.

This powder is often blended with other elements. Lubricants may be added to improve the compaction process, or different metal powders can be mixed to create a specific alloy directly in the part.

Step 2: Compaction (Forming the "Green" Part)

Next, a precisely measured amount of the blended powder is fed into a rigid die or mold.

The powder is then compacted under immense pressure, typically from both above and below. This forces the powder particles into tight contact, forming a fragile, self-supporting component known as a "green" part. This green part has the desired shape and dimensions but possesses very low mechanical strength.

Step 3: Sintering (Applying Heat)

The green parts are carefully placed on ceramic trays and loaded into a high-temperature furnace with a controlled atmosphere. This atmosphere prevents oxidation during heating.

The parts are heated to a temperature below the material’s melting point. At this high temperature, a process of atomic diffusion occurs. Atoms migrate across the boundaries of the individual particles, causing them to fuse together. This shrinks the part, eliminates much of its porosity, and dramatically increases its density, hardness, and strength.

What Happens After Sintering? Secondary Operations

The part that emerges from the furnace is often not the final product. A wide range of secondary and finishing processes can be applied to meet specific engineering requirements.

Enhancing Mechanical Properties

For applications requiring specific properties, sintered parts can be impregnated. Oil impregnation is common for creating self-lubricating bearings, while resin impregnation is used to seal any remaining porosity and make the part pressure-tight.

Improving Surface Finish and Accuracy

While sintering produces near-net-shape parts, high-precision applications may require further finishing. Machining processes like grinding, honing, and lapping can be used to achieve very tight dimensional tolerances and a smooth surface finish. For ceramics, this often requires ultra-hard diamond tools.

Applying Protective Coatings

To improve corrosion resistance or aesthetics, sintered metal parts can be coated. Common processes include galvanizing, nickel plating, chrome plating, and steam oxidation, which forms a durable oxide layer on the surface.

Understanding the Trade-offs of Sintering

Like any manufacturing process, sintering has distinct advantages and limitations that make it suitable for some applications but not others.

Key Advantage: Material Efficiency and Complexity

Sintering excels at producing complex, intricate shapes with minimal material waste. Since the part is built up from powder rather than machined down from a solid block, it is an extremely efficient near-net-shape process. This is especially valuable for expensive or difficult-to-machine materials.

Key Limitation: Inherent Porosity

Unless secondary steps like impregnation or hot isostatic pressing are performed, a sintered part will retain some level of porosity. This can make it less strong than an equivalent part made from wrought metal or a fully dense casting. This porosity must be accounted for in the design phase.

Consideration: Tooling Costs

The hardened steel dies used for compaction are expensive to design and manufacture. This high initial investment means that sintering is most cost-effective for medium-to-high-volume production runs, where the tooling cost can be amortized over thousands or millions of parts.

Is Sintering the Right Choice for Your Project?

Use these guidelines to determine if sintering aligns with your goals.

- If your primary focus is cost-effective volume production of complex parts: Sintering is an exceptional choice for creating thousands of identical metal components where the high cost of tooling is justified by a low per-part price.

- If your primary focus is working with high-performance materials: Sintering is one of the only viable methods for shaping ceramics or refractory metals (like tungsten) that have extremely high melting points.

- If your primary focus is creating parts with unique properties: Choose sintering for specialized applications like porous filters or self-lubricating bearings that depend on controlled porosity and oil impregnation.

By understanding the complete process from powder to finished component, you can confidently leverage sintering to achieve your specific design and manufacturing goals.

Summary Table:

| Stage | Key Process | Outcome |

|---|---|---|

| 1. Preparation | Blending fine metal/ceramic powders | Uniform raw material mix |

| 2. Compaction | Pressing powder in a die under high pressure | "Green" part with preliminary shape |

| 3. Sintering | Heating in a controlled atmosphere furnace | Atoms diffuse, part gains strength & density |

| 4. Finishing | (Optional) Impregnation, machining, or coating | Final part meets specific requirements |

Ready to leverage sintering for your lab's unique component needs? KINTEK specializes in providing the high-quality lab equipment and consumables essential for advanced manufacturing processes like sintering. Whether you're developing new materials or scaling up production, our expertise ensures you have the right tools for precision and efficiency. Contact our experts today to discuss how we can support your laboratory's sintering and powder metallurgy projects.

Visual Guide

Related Products

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- At what temperature does wood pyrolysis begin? Control the Process for Biochar, Bio-Oil, or Syngas

- What is the temperature of a rotary hearth furnace? Find the Right Heat for Your Process

- What are the process advantages of using a rotary tube furnace for WS2 powder? Achieve Superior Material Crystallinity

- What is the function of a high-temperature furnace during burnout? Master Aluminum Foam Production with Precision

- How are tube furnaces classified based on the orientation of the tube? Choose the Right Design for Your Process