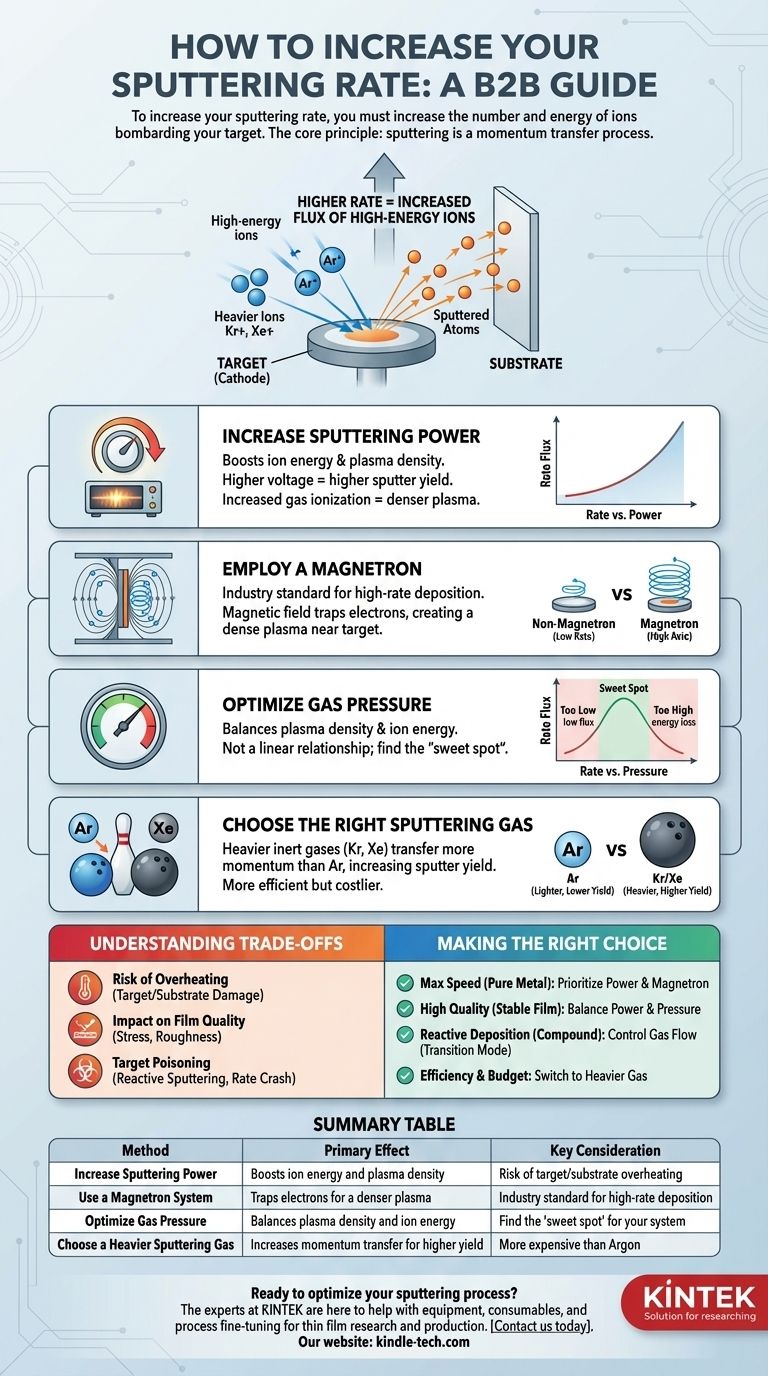

To increase your sputtering rate, you must increase the number and energy of ions bombarding your target. The most direct methods are to increase the sputtering power and to use a magnetron system, which employs a magnetic field to trap electrons and create a much denser plasma near the target. Optimizing the sputtering gas type and pressure are also critical levers for enhancing deposition speed.

The core principle is simple: sputtering is a momentum transfer process. A higher sputtering rate is the direct result of increasing the flux of high-energy ions striking the target, which in turn ejects more atoms. All methods for increasing the rate are ultimately designed to achieve this.

The Physics of a Faster Sputter

Sputtering works by accelerating gas ions (like Argon, Ar+) into a material target. When these ions collide with the target, they physically knock out, or "sputter," atoms from the surface. These sputtered atoms then travel and deposit onto your substrate as a thin film.

The Role of Plasma Density

Plasma is the source of the ions. A denser plasma contains more ions per unit volume.

A higher plasma density directly translates to a higher flux of ions arriving at the target surface, which means more individual collision events and more atoms sputtered per second.

The Role of Ion Energy

The energy of the striking ions determines how many atoms are ejected per individual impact, a factor known as the sputter yield.

Higher-energy ions transfer more momentum upon collision, leading to a higher sputter yield. This energy is primarily controlled by the voltage applied to the target (cathode).

Key Levers for Increasing Sputtering Rate

You have several variables you can control to influence plasma density and ion energy.

Increase Sputtering Power

This is the most straightforward method. Increasing the power (wattage) delivered to the cathode has two primary effects:

- It increases the target voltage, accelerating ions to higher energies and thus increasing the sputter yield.

- It boosts the ionization of the sputtering gas, leading to a denser plasma and higher ion current.

Employ a Magnetron

This is the single most effective technique for dramatically increasing the rate. Magnetron sputtering is the industry standard for high-rate deposition.

A magnetic field is configured behind the target to trap secondary electrons emitted from the target surface. These electrons are forced into long, helical paths near the target, drastically increasing their chances of colliding with and ionizing neutral gas atoms.

This process creates a very dense plasma confined directly in front of the target, leading to a massive increase in ion bombardment and a sputtering rate that can be orders of magnitude higher than non-magnetron systems.

Optimize Gas Pressure

The relationship between pressure and sputter rate is not linear; there is an optimal range.

- Too low: Insufficient gas atoms are available to create a dense, stable plasma, resulting in a low ion flux.

- Too high: Ions collide with other gas atoms on their way to the target. These collisions reduce the ions' energy and scatter them, lowering the sputter yield and deposition efficiency.

You must find the "sweet spot" for your specific chamber geometry and material where plasma density is high but the mean free path is still long enough for efficient energy transfer.

Choose the Right Sputtering Gas

The mass of the sputtering gas ion has a significant impact on momentum transfer.

Heavier inert gases like Krypton (Kr) or Xenon (Xe) are more efficient at sputtering than Argon (Ar) because their higher mass transfers momentum more effectively, like hitting a bowling pin with a bowling ball instead of a baseball. While more expensive, these gases can provide a significant rate increase.

Understanding the Trade-offs

Simply maximizing the rate can introduce new problems. A successful process requires balancing speed with quality.

Risk of Overheating

Higher power and ion flux generate significant heat in the target. Without adequate cooling, the target can crack, melt, or debond from its backing plate. This heat can also radiate to the substrate, potentially damaging it or altering the film's properties.

Impact on Film Quality

A very high deposition rate doesn't always produce the best film. It can sometimes lead to higher internal stress, increased surface roughness, or a less dense film microstructure. The optimal rate often depends on the desired film characteristics for your application.

The "Poisoning" Effect in Reactive Sputtering

When using reactive gases (like O₂ or N₂) to deposit compounds (oxides, nitrides), the process changes. If the reactive gas flow is too high relative to the metal sputter rate, the target surface itself becomes coated with the compound.

This is called target poisoning. Because ceramics and compounds typically have a much lower sputter yield than pure metals, this effect causes the deposition rate to crash dramatically.

Making the Right Choice for Your Goal

Your strategy should be guided by your end goal.

- If your primary focus is maximum speed for a pure metal: Prioritize using a well-designed magnetron and increasing the power to the thermal limit of your target cooling system.

- If your primary focus is a stable, high-quality film: Methodically co-optimize your sputtering power and gas pressure to find a balance point, rather than simply maximizing one variable.

- If your primary focus is reactive deposition of a compound: Carefully control the reactive gas flow to operate in the "transition mode" just before severe target poisoning occurs to balance rate with correct film stoichiometry.

- If your primary focus is efficiency and you have a budget: Consider switching from Argon to a heavier inert gas like Krypton to increase sputter yield without changing other parameters.

By understanding these fundamental levers, you can systematically tune your process to achieve the optimal balance of deposition speed and film quality for your specific application.

Summary Table:

| Method | Primary Effect | Key Consideration |

|---|---|---|

| Increase Sputtering Power | Boosts ion energy and plasma density | Risk of target/substrate overheating |

| Use a Magnetron System | Traps electrons for a denser plasma | Industry standard for high-rate deposition |

| Optimize Gas Pressure | Balances plasma density and ion energy | Find the 'sweet spot' for your system |

| Choose a Heavier Sputtering Gas (e.g., Kr, Xe) | Increases momentum transfer for higher yield | More expensive than Argon |

Ready to optimize your sputtering process for maximum speed and quality? The experts at KINTEK are here to help. Whether you need to upgrade to a high-performance magnetron system, select the right consumables, or fine-tune your deposition parameters, our team provides the equipment and support to meet your laboratory's specific needs. Contact us today to discuss how we can enhance your thin film research and production!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What are 3 pros and cons of biomass? Weighing the Sustainability of Renewable Energy

- What is the difference between internal and external quenching? A Guide to Fluorescence Quenching Mechanisms

- What happens to steel after annealing? Unlock Superior Machinability and Formability

- How do high-energy mixing systems improve slurry-bed photocatalytic reactors? Maximize Your Catalyst Efficiency

- What is the residence time in flash pyrolysis? A Sub-2-Second Race for Maximum Bio-Oil

- How does the sample size affect the needed accuracy of the measurement? Optimize Your Data Quality

- Can glass be sintered? Unlock Complex Shapes and Advanced Materials with Powder Processing

- What is the best prevention for CVD? A Lifelong Strategy for Optimal Heart Health