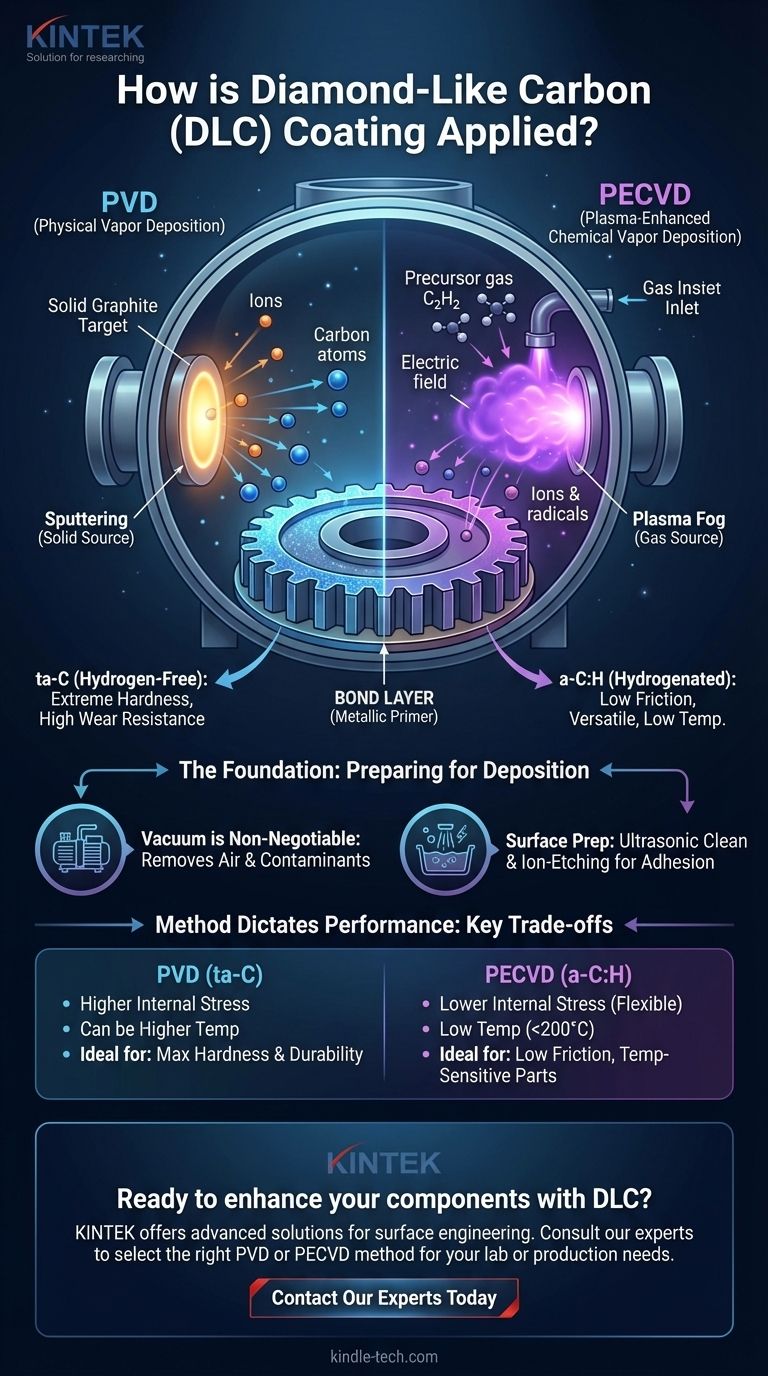

At its core, applying a diamond-like carbon (DLC) coating is a vacuum deposition process, not a simple wet-application like paint. The most common methods are Plasma-Enhanced Chemical Vapor Deposition (PECVD), which uses a precursor gas, and Physical Vapor Deposition (PVD), which uses a solid carbon target. The component to be coated is placed in a vacuum chamber where a combination of high-energy plasma and electric fields causes carbon atoms to deposit onto its surface, forming a thin, hard film.

The specific application method chosen is not merely a process detail—it is the single most important factor that determines the coating's final properties, including its hardness, friction, and internal stress. Understanding the difference between these methods is essential to selecting a DLC coating that will actually solve your engineering problem.

The Foundation: Preparing for Deposition

All advanced DLC application methods take place in a high-vacuum environment. This is not optional; it is fundamental to the quality and adhesion of the coating.

Why a Vacuum is Non-Negotiable

A vacuum chamber is pumped down to remove atmospheric gases like oxygen, nitrogen, and water vapor. Any of these residual molecules would contaminate the coating, creating a weak, porous film that would fail in service. The vacuum ensures only the desired carbon atoms reach the part's surface.

The Critical Role of Surface Preparation

Before entering the chamber, every component must undergo a multi-stage, ultrasonic cleaning process to remove all oils, greases, and particulates. The final step often occurs inside the chamber itself, where an ion-etching process uses plasma to microscopically sandblast the surface, ensuring it is atomically clean for maximum adhesion.

Core Application Methods: PVD vs. PECVD

While there are many variations, nearly all commercial DLC applications fall into two main families: Physical Vapor Deposition (PVD) and Plasma-Enhanced Chemical Vapor Deposition (PECVD).

Physical Vapor Deposition (PVD)

PVD physically transports carbon from a solid source to the component's surface. Think of it as a microscopic spray of atoms.

The most common PVD method for DLC is sputtering. In this process, high-energy argon ions bombard a solid graphite target. This impact "sputters" or ejects carbon atoms, which then travel through the vacuum and deposit onto your part.

PVD methods are often used to create extremely hard, hydrogen-free DLC known as tetrahedral amorphous carbon (ta-C).

Plasma-Enhanced Chemical Vapor Deposition (PECVD)

PECVD builds the coating from a chemical gas precursor. Think of it as creating a specialized fog that condenses and solidifies into a film.

In this method, a hydrocarbon gas (like acetylene, C₂H₂) is introduced into the chamber. A powerful electric field ignites the gas into a plasma, which breaks the molecules apart into carbon and hydrogen ions. A negative voltage bias applied to the part accelerates these positive ions towards it, where they build up to form the coating.

This method produces hydrogenated amorphous carbon (a-C:H), the most common and versatile form of DLC.

Understanding the Trade-offs: Method Dictates Performance

Choosing between PECVD and PVD is an engineering decision based on the required outcome. The application process directly controls the coating's microstructure and, therefore, its performance.

The Hydrogen Factor: a-C:H vs. ta-C

PECVD processes inherently incorporate hydrogen into the film, creating a-C:H. This hydrogen lowers the coating's internal stress, making it more flexible and often providing a very low coefficient of friction.

PVD sputtering, on the other hand, can create ta-C, a nearly hydrogen-free film. These coatings have a much higher percentage of diamond-like bonds (sp³), making them significantly harder and more wear-resistant, but often with higher internal stress.

Temperature Sensitivity of the Substrate

PECVD is generally a lower-temperature process, often operating below 200°C (400°F). This makes it ideal for coating temperature-sensitive materials like certain tool steels, aluminum alloys, or even some polymers, without altering their underlying properties.

Some PVD processes can require higher temperatures, which must be accounted for when selecting a base material.

The Unseen Step: The Bond Layer

The DLC film itself rarely adheres directly to the substrate. A critical, intermediate step is the deposition of a metallic bond layer (often chromium, titanium, or silicon) just a few nanometers thick. This layer acts as a "primer," ensuring the subsequent DLC layer has a strong, chemical anchor to the part.

Making the Right Choice for Your Goal

The best application method is defined entirely by your primary objective. Consult with your coating provider about your specific needs, but use these principles as a guide.

- If your primary focus is extreme hardness and wear resistance: A hydrogen-free ta-C coating, typically applied via a PVD method like arc or sputtering, is likely the best choice.

- If your primary focus is low friction and versatility: A hydrogenated a-C:H coating applied via PECVD is the industry standard and provides an excellent balance of properties for most mechanical components.

- If your primary focus is coating a temperature-sensitive material: You must specify a low-temperature PECVD process to prevent damage or distortion to your component.

By understanding how the application method shapes the final material, you can specify the precise DLC coating that solves your engineering challenge.

Summary Table:

| Method | Coating Type | Key Characteristics | Ideal For |

|---|---|---|---|

| PVD (Physical Vapor Deposition) | ta-C (Hydrogen-free) | Extreme hardness, high wear resistance, higher internal stress | Components requiring maximum hardness and durability |

| PECVD (Plasma-Enhanced Chemical Vapor Deposition) | a-C:H (Hydrogenated) | Excellent low friction, versatile, lower temperature process | General mechanical components, temperature-sensitive materials |

Ready to enhance your components with a high-performance DLC coating?

Selecting the right application method is critical to achieving the specific hardness, friction, and durability your project demands. KINTEK specializes in advanced lab equipment and consumables for materials science, including solutions for surface engineering. Our expertise can help you navigate the complexities of PVD and PECVD to ensure optimal results for your laboratory or production needs.

Contact our experts today to discuss how we can support your DLC coating applications and provide the right equipment for your laboratory.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Isostatic Molding Pressing Molds for Lab

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the drawbacks of PECVD? Understanding the Trade-offs of Low-Temperature Deposition

- What are the components of PECVD? A Guide to Low-Temperature Thin Film Deposition Systems