To carbonize charcoal, you must heat an organic material like wood or biomass briquettes in a low-oxygen environment. This process, known as pyrolysis, is not simple burning; it is a controlled thermal decomposition that drives off water, volatile compounds, and gases, leaving behind a substance with a high concentration of pure carbon.

The core principle of carbonization is controlled transformation, not combustion. By precisely managing heat and restricting oxygen, you systematically break down raw biomass to purify its carbon content, turning volatile materials into a stable, energy-dense charcoal.

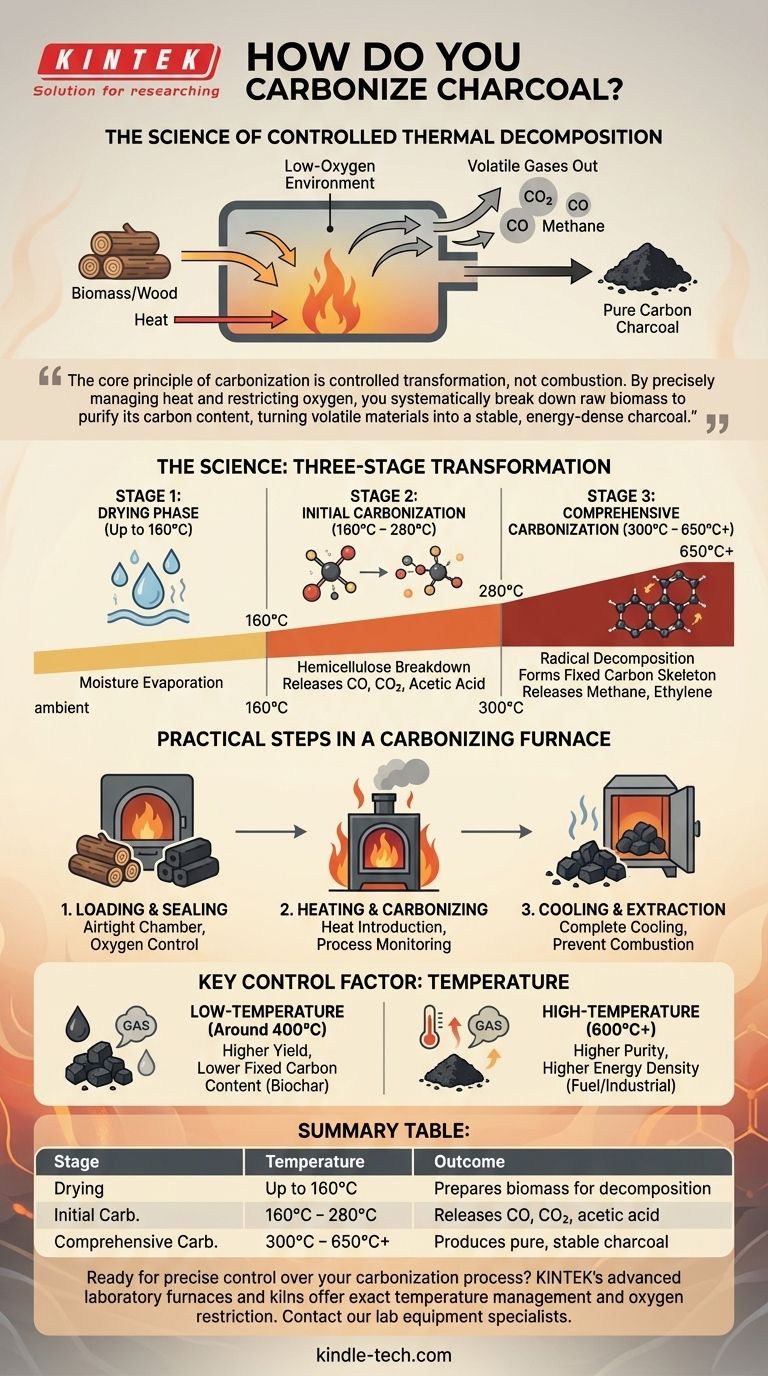

The Science of Carbonization: A Three-Stage Transformation

Carbonization is a progressive chemical change. As the temperature rises inside a sealed furnace or kiln, the raw material undergoes three distinct phases to become charcoal.

Stage 1: The Drying Phase (Up to 160°C)

The initial application of heat is focused on one goal: driving out moisture. All the water contained within the cells of the biomass evaporates, preparing the material for the chemical changes to come.

Stage 2: Initial Carbonization (160°C – 280°C)

Once the water is gone, the material begins to decompose. Less stable compounds, such as hemicellulose, break down. This stage releases gases like carbon dioxide (CO2), carbon monoxide (CO), and small amounts of acetic acid.

Stage 3: Comprehensive Carbonization (300°C – 650°C+)

This is the critical phase where true charcoal is formed. The temperature triggers a radical chemical decomposition of the remaining organic matter. More complex compounds break down, releasing combustible gases like methane and ethylene, along with byproducts like wood tar and carbinol. What remains is the fixed carbon skeleton—the charcoal itself.

The Practical Steps in a Carbonizing Furnace

While the science is complex, the operational steps are straightforward and focus on creating the correct environment for the transformation.

Step 1: Loading and Sealing

The raw material, such as wood logs or biomass briquettes, is placed into the carbonizing furnace or kiln. The chamber is then sealed airtight to control the oxygen supply.

Step 2: Heating and Carbonizing

Heat is introduced to the sealed chamber, initiating the three-stage process described above. The operator monitors the process, often by observing the color and density of the smoke exiting the vents.

Step 3: Cooling and Extraction

After the carbonization is complete, the charcoal must be allowed to cool down completely before being exposed to air. Opening the chamber too soon will cause the hot charcoal to ignite and burn to ash. Once cool, the finished charcoal is removed.

Understanding the Key Control Factor

The quality and type of charcoal produced are not left to chance. They are the direct result of how you manage the carbonization environment.

The Decisive Role of Temperature

The final temperature dictates the charcoal's properties. By adjusting the airflow into the furnace, you control the rate of heating and the maximum temperature reached.

Low-Temperature vs. High-Temperature Charcoal

A lower final temperature (around 400°C) produces a higher yield of charcoal but with a lower fixed carbon content. Conversely, a higher temperature (600°C+) results in a purer, more energy-dense charcoal but with a lower overall yield, as more of the material is converted into gas.

Making the Right Choice for Your Goal

The ideal carbonization process depends entirely on the desired characteristics of the final product.

- If your primary focus is maximizing yield (e.g., for biochar): Employ a lower-temperature process to preserve more of the material's mass as solid carbon.

- If your primary focus is high purity and energy density (e.g., for fuel or industrial use): Utilize a high-temperature process to drive off nearly all volatile matter, leaving almost pure carbon.

Ultimately, mastering carbonization is about the precise control of heat and the strategic starvation of oxygen.

Summary Table:

| Stage | Temperature Range | Key Process | Outcome |

|---|---|---|---|

| Drying | Up to 160°C | Moisture evaporation | Prepares biomass for decomposition |

| Initial Carbonization | 160°C – 280°C | Hemicellulose breakdown | Releases CO, CO2, acetic acid |

| Comprehensive Carbonization | 300°C – 650°C+ | Radical decomposition of organic matter | Produces pure, stable charcoal |

Ready to achieve precise control over your carbonization process? Whether your goal is high-yield biochar or high-purity industrial charcoal, KINTEK's advanced laboratory furnaces and kilns are engineered for exact temperature management and oxygen restriction. Our experts will help you select the ideal equipment to optimize yield, purity, and energy density for your specific biomass. Contact our lab equipment specialists today to discuss your project and get a personalized solution. Get in touch via our Contact Form

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What temperature is needed for porcelain? A Guide to Cone 6 and Cone 10 Firing

- What is the temperature of a rotary hearth furnace? Find the Right Heat for Your Process

- What temperature is a carbon regeneration kiln? Master the 650°C-800°C Range for Optimal Results

- What is the temperature of a carbon regeneration kiln? Mastering the 750-800°C Reactivation Process

- Can you restore activated carbon? Understanding the Industrial Reactivation Process