At its core, a muffle furnace is controlled using a dedicated automatic temperature controller. This external unit acts as the brain of the operation, receiving temperature readings from a thermocouple inside the furnace and adjusting the power to the heating elements to precisely match your set temperature. This process relies on a constant feedback loop to maintain a stable, high-temperature environment.

Controlling a muffle furnace is not just about turning a dial. It's a systematic process involving the correct physical setup of the controller and thermocouple, understanding the automatic feedback loop that maintains heat, and adhering to strict safety protocols to protect both the operator and the equipment.

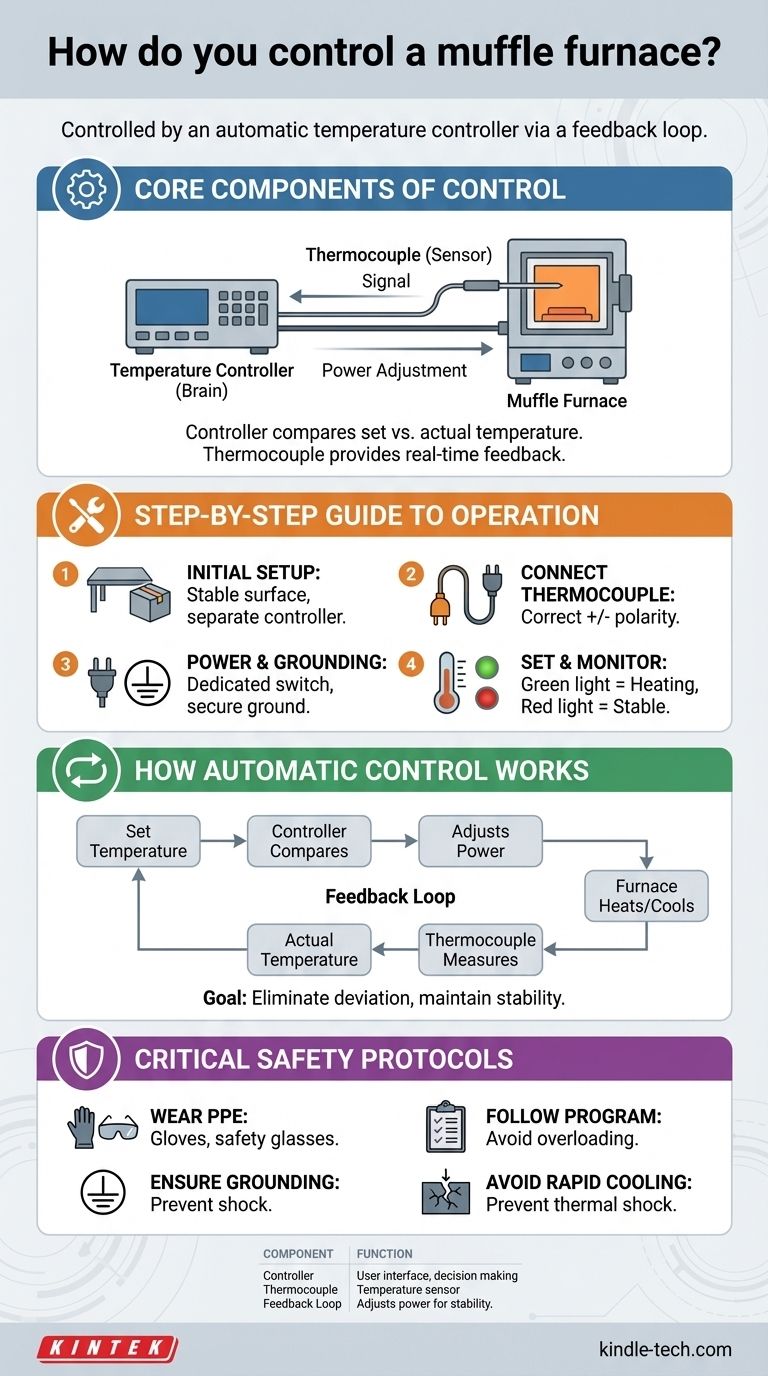

The Core Components of Control

A muffle furnace's control system is deceptively simple, consisting of two primary components that work in tandem. Understanding their roles is the first step to effective operation.

The Temperature Controller

The temperature controller is the user interface and the decision-making center. It's where you input your desired temperature and heating program.

Internally, it constantly compares the target temperature you've set with the actual temperature being measured inside the furnace.

The Thermocouple

The thermocouple is the system's sensory organ. It's a temperature-sensing probe inserted into the furnace chamber.

It generates a voltage signal proportional to the heat it detects, sending this crucial information back to the controller as real-time feedback.

A Step-by-Step Guide to Operation

Proper control begins with proper setup. Following a methodical process ensures accuracy, safety, and repeatable results.

Initial Setup and Placement

First, place the furnace on a flat, stable surface. The controller should be positioned away from the furnace body to prevent its electronic components from overheating.

Connecting the Thermocouple

Insert the thermocouple into the designated port in the furnace, ensuring it extends sufficiently into the chamber. The connection wires must be run to the controller, paying strict attention to the correct positive (+) and negative (-) polarity.

Power and Grounding

A dedicated power switch must be installed at the main power line for safety. It is absolutely critical that both the furnace and the controller are securely grounded to prevent electrical shock.

Setting and Monitoring the Temperature

After completing the wiring, you can set your desired temperature on the controller. Once the power is switched on, the system will begin its work.

Most controllers use simple indicator lights: a green light typically signifies that the furnace is actively heating, while a red light indicates it has reached the set temperature and is now in a stable, constant state.

How Automatic Control Actually Works

The "magic" of a muffle furnace holding a precise temperature is based on a straightforward engineering principle: a feedback loop.

The Principle of Feedback

The controller's job is to eliminate any deviation between your set temperature and the actual furnace temperature.

Think of it like a thermostat in your home. The controller measures the current temperature via the thermocouple, compares it to your target, and then adjusts the power to the heating elements to correct any difference.

Common Control Methods

This adjustment can be a simple on/off action (known as two-position control) or a more sophisticated, continuous adjustment of power (proportional, integral, and derivative, or PID, control).

The ultimate goal of any method is to supply just enough energy to counteract heat loss and maintain a stable temperature within a very narrow range.

Understanding the Trade-offs and Critical Safety Protocols

Controlling extreme heat demands unwavering attention to safety. These are not suggestions; they are requirements for safe and effective operation.

Before You Begin

Always wear appropriate Personal Protective Equipment (PPE), including heat-resistant gloves and safety glasses. Ensure the furnace is properly grounded and that the surrounding area is well-ventilated and clear of any combustible materials.

During Operation

Strictly follow the manufacturer's recommended heating program. Avoid overloading the chamber, which can lead to non-uniform heating. Never place flammable or explosive materials inside the furnace.

Crucially, avoid rapid cooling or opening the door at high temperatures, as the resulting thermal shock can crack the furnace's insulating material.

After Use

Once your process is complete, turn off the power at the main switch. If any malfunction occurs during operation, shut down the system immediately and have it inspected by a qualified technician.

Making the Right Choice for Your Goal

How you approach controlling the furnace depends on your objective.

- If your primary focus is precision and repeatability: Take the time to understand your controller's specific functions, like PID settings, and always use a programmed heating and cooling cycle.

- If your primary focus is safety and equipment longevity: Prioritize gradual heating and cooling cycles to prevent thermal shock, and perform regular checks of the thermocouple and wiring.

- If your primary focus is processing efficiency: Ensure workpieces are placed to allow for homogeneous heat transfer and avoid overloading the chamber, which compromises temperature uniformity.

Ultimately, mastering your muffle furnace comes from treating it as a precision instrument that demands a methodical and safety-conscious approach.

Summary Table:

| Control Component | Primary Function |

|---|---|

| Temperature Controller | User interface and decision-making center; compares setpoint with actual temperature. |

| Thermocouple | Temperature-sensing probe; provides real-time feedback to the controller. |

| Feedback Loop | Automatic system that adjusts heating power to maintain a stable set temperature. |

Ready to achieve precise, reliable, and safe high-temperature processing in your lab?

KINTEK specializes in high-quality lab equipment, including muffle furnaces designed for accuracy and durability. Our experts can help you select the right furnace and controller for your specific application, ensuring optimal performance and safety.

Contact our team today to discuss your laboratory heating needs and discover how KINTEK can support your research and processing goals.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the function of a solution treatment furnace? Activating CuAlMn Shape Memory Alloys

- What properties are sintered? Master Your Material's Strength, Conductivity & Translucency

- Why is a high-precision furnace essential for PH stainless steels? Master Microstructure for Shielding Performance

- How do the requirements for temperature control in sintering equipment affect Cu-Al2O3 internal oxidation at 950°C?

- Why is a high-temperature resistance furnace required for Inconel 625 SLM post-processing? Ensure Material Integrity

- What is the temperature for sintering? A Guide to Material-Specific Ranges and Trade-offs

- Why is precise heating rate control critical for tungsten oxide annealing? Preserve Delicate Nanostructures

- What is the effect of sintering temperature on ceramics? Master the Key to Ceramic Density & Strength