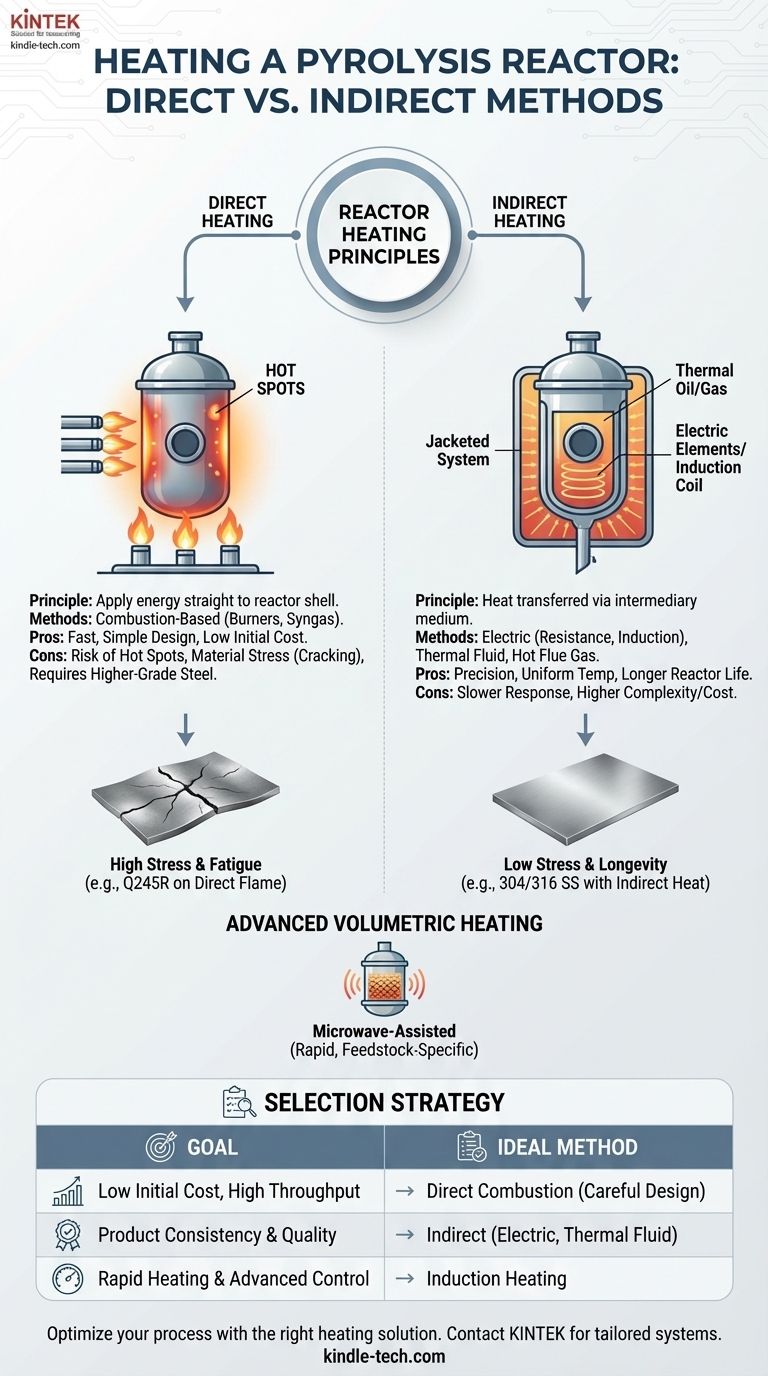

At its core, heating a pyrolysis reactor involves transferring a tremendous amount of energy into an oxygen-free chamber to thermally decompose material. The primary methods to achieve this are broadly categorized into two approaches: direct heating, where the heat source is applied straight to the reactor's outer shell, and indirect heating, which uses an intermediary medium like hot gas, thermal oil, or electricity to provide a more controlled and uniform temperature.

The fundamental decision in reactor heating is a trade-off between the simplicity and rapid response of direct heating versus the precision, uniformity, and material longevity offered by indirect heating methods. Your choice directly impacts operational control, product consistency, and the reactor's lifespan.

The Two Principles of Reactor Heating

Understanding the difference between direct and indirect heating is the first step in designing or selecting a pyrolysis system. Each philosophy has significant implications for cost, control, and maintenance.

Direct Heating: Applying Energy Straight to the Source

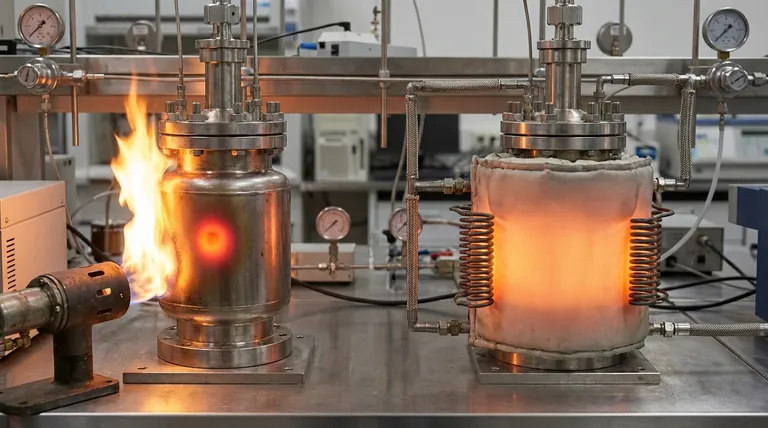

Direct heating is the most straightforward concept. It involves applying the heat source, typically a flame from a burner, directly onto the surface of the pyrolysis reactor.

This method is analogous to holding a pot directly over a high-power gas flame. The energy transfer is fast and intense.

Common fuel sources for direct heating include natural gas, diesel, or even the non-condensable syngas produced by the pyrolysis process itself, creating a self-sustaining loop.

Indirect Heating: Precision Through an Intermediary

Indirect heating separates the primary heat source from the reactor wall. Energy is first transferred to a secondary medium, which then uniformly heats the reactor.

This is like placing your pot in a pre-heated oven. The heat is less intense at any single point but envelops the target evenly.

Methods include circulating hot flue gas around the reactor, using a jacket filled with thermal oil or molten salt, or wrapping the reactor with electric resistance heaters.

A Deeper Look at Heating Technologies

While the principles are simple, the specific technologies used to implement them vary in complexity, efficiency, and cost.

Combustion-Based Systems

This is the most common method, utilizing the combustion of fuel to generate heat. Burners can be configured for both direct and indirect heating.

In a direct-fired rotary kiln, for example, burners are aimed at the rotating shell. In an indirect system, the burners might heat a "hot box," with the hot exhaust gases then ducted to flow around the stationary reactor vessel.

Electric Heating

Electric heating offers unparalleled precision and cleanliness at the point of use, though it can be more expensive to operate depending on electricity costs.

Resistance heating involves wrapping the reactor with high-power heating elements, similar to an electric kiln. It provides excellent, zoned temperature control.

Induction heating is a more advanced technique. It uses an electromagnetic coil to induce an electric current directly within the reactor's metal wall, causing it to heat up rapidly and uniformly from within.

Advanced Volumetric Heating

For certain applications, energy can be introduced in a way that heats the feedstock material itself, not just the reactor walls.

Microwave-assisted pyrolysis uses microwaves to directly excite and heat polar molecules within the feedstock (like water). This can lead to extremely rapid and efficient heating but is typically limited to smaller-scale or specialized systems.

Understanding the Trade-offs: Heat vs. Material Integrity

The choice of heating method has a direct and critical impact on the reactor's structural health and lifespan. The reference to materials like Q245R boiler plate and 304/316 stainless steel is central to this problem.

The Danger of Hot Spots

Direct flame impingement is notorious for creating hot spots—localized areas on the reactor shell that are significantly hotter than the average temperature.

These hot spots create immense thermal stress and can dramatically accelerate material fatigue, corrosion, and creep. Over time, this can lead to warping, cracking, and catastrophic reactor failure.

Heat Transfer Rate vs. Material Stress

The rate at which you heat and cool the reactor induces thermal stress. Indirect methods, particularly those using thermal fluids or controlled electric elements, allow for programmed, gradual temperature ramps.

This controlled process minimizes thermal shock and is much gentler on the reactor's welds and structure, extending its operational life.

Matching Material to Method

High-temperature, direct-fired systems almost always demand superior materials like 304 or 316 stainless steel. These alloys maintain their strength at high temperatures and resist the oxidation and corrosion accelerated by hot spots.

Using a lower-grade material like Q245R boiler steel in a direct-fired application is a significant risk. However, for a lower-temperature process using a well-controlled indirect heating method (like a thermal oil jacket), such a material might be a viable, cost-effective choice.

Selecting the Right Heating Strategy for Your Goal

Your choice must be guided by your primary objective, whether it's minimizing capital cost, maximizing product quality, or achieving high throughput.

- If your primary focus is low initial cost and simplicity: Direct combustion heating is often the most economical choice, but it requires careful burner design and potentially higher-grade materials to mitigate the risk of hot spots.

- If your primary focus is product consistency and quality: Indirect heating via electric elements, thermal fluid, or molten salt provides the superior temperature control needed to produce a consistent output.

- If your primary focus is rapid heating and advanced process control: Induction heating offers unmatched speed and uniformity, while microwave heating can provide unique benefits for specific feedstocks, though both come at a higher cost and complexity.

Ultimately, your heating system is not just an accessory; it is a fundamental component that dictates the performance, safety, and economic viability of your entire pyrolysis operation.

Summary Table:

| Heating Method | Principle | Key Features | Ideal For |

|---|---|---|---|

| Direct Heating | Flame applied directly to reactor shell | Fast heating, simpler design, risk of hot spots | Low initial cost, high throughput |

| Indirect Heating | Heat transferred via medium (oil, gas, electricity) | Uniform temperature, precise control, longer reactor life | Product consistency, material longevity |

| Electric/Induction | Clean, zoned, or internal heating via electricity | High precision, rapid response, higher operational cost | Advanced control, specialized applications |

Optimize your pyrolysis process with the right heating solution. The choice between direct and indirect heating is critical for your reactor's efficiency, product quality, and lifespan. At KINTEK, we specialize in lab equipment and consumables, providing tailored pyrolysis systems that match your specific needs—whether you prioritize cost, control, or durability. Contact our experts today to design a heating strategy that ensures your laboratory's success!

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What is the contribution of a hydrothermal reactor to graded pore construction? Precision Templates for TAS

- How does a high-pressure reactor demonstrate its value in accelerated aging? Predict Catalyst Durability Fast

- What is the purpose of using high-purity argon gas in a high-pressure reactor? Ensure Precise Corrosion Test Data

- What is the role of high-pressure reactors in the study of alloy oxidation? Essential Tools for Supercritical Research

- Why are sealed laboratory reaction vessels necessary in the hydrothermal synthesis of zeolites? Ensure Purity and Yield