To melt metal in a crucible, you must place your solid metal charge into the crucible, position it securely within a furnace, and apply sufficient, controlled heat. As the furnace temperature rises past the metal's specific melting point, the metal will transition from a solid to a liquid state, ready for casting.

The core principle of melting metal is not just about brute-force heat, but about using a controlled system. Success and safety depend on matching the right crucible material to the right furnace type for the specific metal you intend to melt.

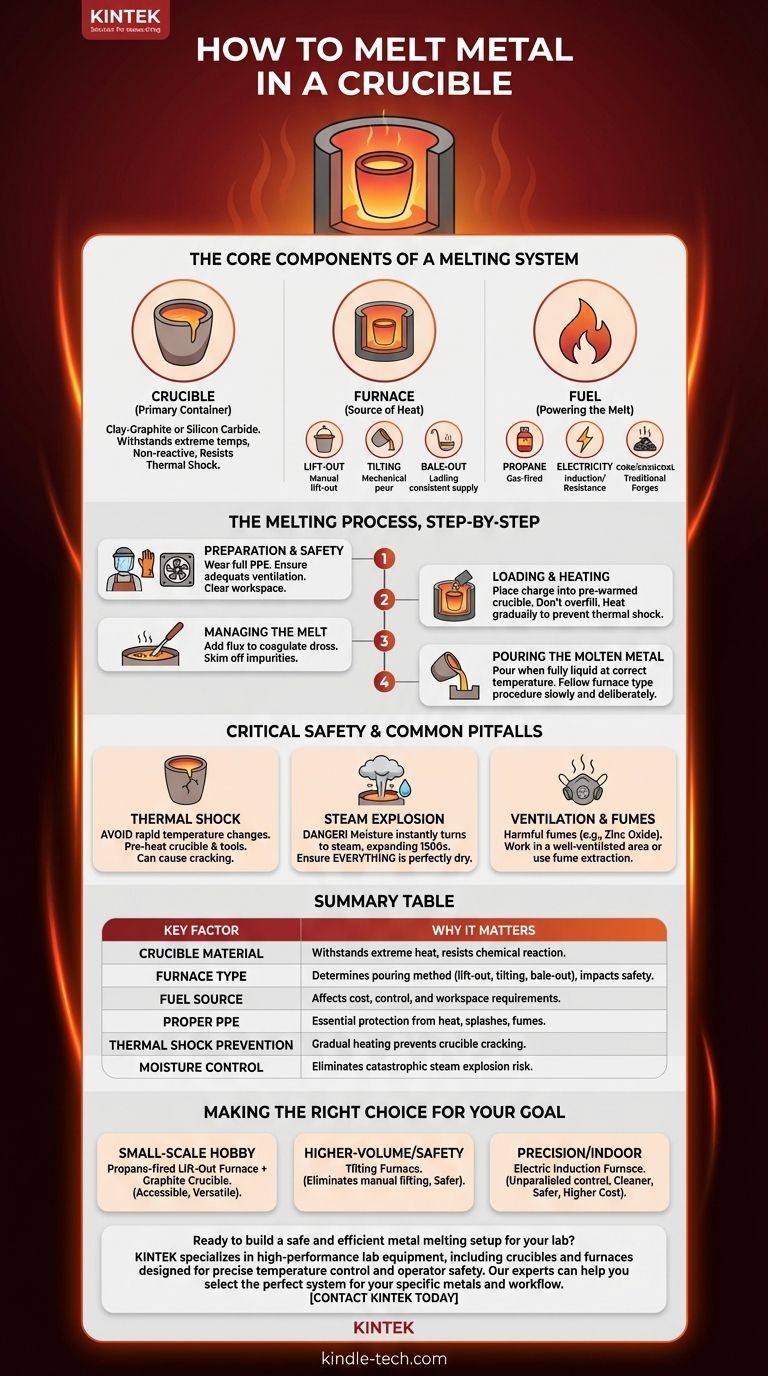

The Core Components of a Melting System

Melting metal is an integrated process. Understanding the function of each piece of equipment is critical to achieving a safe and effective melt.

The Crucible: Your Primary Container

A crucible is a ceramic or graphite-based pot designed to withstand extreme temperatures far beyond the melting point of most common metals. They are made from materials like clay-graphite or silicon carbide.

The choice of material is crucial, as it must be chemically non-reactive with the molten metal it holds and resistant to thermal shock—the cracking that can occur from rapid temperature changes.

The Furnace: The Source of Heat

The furnace's job is to contain and concentrate heat onto the crucible. Furnaces are generally categorized by how the molten metal is removed, which directly impacts your workflow.

- Lift-Out Furnace: The entire crucible is "lifted out" of the furnace using specialized tongs for pouring. This is common for smaller, hobbyist setups.

- Tilting Furnace: The furnace and crucible are built into a single unit that tilts mechanically to pour the metal. This design is safer for larger volumes as it avoids carrying a crucible full of liquid metal.

- Bale-Out Furnace: The crucible remains stationary inside the furnace, and molten metal is ladled out. This is often used in die-casting operations where a consistent supply of liquid metal is needed.

The Fuel: Powering the Melt

The heat itself is generated by a fuel source. Common options include propane (found in gas-fired furnaces), electricity (used in induction or resistance furnaces for clean, precise control), or solid fuels like coke and charcoal used in traditional forges.

The Melting Process, Step-by-Step

While specifics vary by metal and equipment, the fundamental process follows a clear sequence of events.

Step 1: Preparation and Safety

Before introducing any heat, ensure you are wearing the proper Personal Protective Equipment (PPE). This includes a full face shield, heat-resistant gloves, a leather or flame-retardant apron, and closed-toe leather boots. Ensure your workspace is clear of flammable materials and has adequate ventilation.

Step 2: Loading and Heating the Crucible

Place your metal—known as the "charge"—into the cold or slightly pre-warmed crucible. Do not fill it to the brim, as the metal will expand.

Place the crucible in the center of your furnace. Apply heat gradually at first to drive off any moisture and prevent thermal shock, which could crack the crucible. Then, increase the heat to bring the furnace to the target temperature.

Step 3: Managing the Melt

As the metal melts, impurities, or "dross," will float to the surface. You can add a small amount of flux, a chemical cleaning agent, which helps coagulate these impurities so they can be skimmed off with a steel tool.

Step 4: Pouring the Molten Metal

Once the metal is fully liquid and at the correct pouring temperature, it is time to pour. The method depends entirely on your furnace type, as discussed previously. Whether lifting the crucible out, tilting the furnace, or ladling the metal, all movements should be slow, deliberate, and confident.

Critical Safety and Common Pitfalls

Ignoring the inherent risks of working with molten metal can lead to severe injury or equipment failure. Understanding these trade-offs is non-negotiable.

The Danger of Thermal Shock

Placing a cold crucible into a red-hot furnace or adding cold metal to an already molten pool can cause the crucible to crack or even shatter from the rapid temperature differential. Always pre-heat your crucible and any tools or additional metal you plan to introduce to the melt.

The Risk of a Steam Explosion

This is the single most dangerous and violent risk in metal casting. If any water or moisture—even from a damp tool or piece of scrap—is introduced to a pool of molten metal, it will flash-vaporize into steam and expand over 1,500 times its original volume. This causes a catastrophic explosion that throws molten metal everywhere. Ensure all tools, charge material, and molds are perfectly dry.

Ventilation and Fume Management

Melting metals, particularly alloys like brass or bronze, can release harmful fumes (e.g., zinc oxide). Always work in a well-ventilated area or with a dedicated fume extraction system to avoid respiratory damage.

Making the Right Choice for Your Goal

Your equipment choice should be guided by your project's scale, budget, and safety priorities.

- If your primary focus is small-scale hobby casting: A propane-fired, lift-out furnace with a graphite crucible offers the most accessible and versatile entry point.

- If your primary focus is higher-volume production or safety: A tilting furnace is a superior choice, as it eliminates the need to manually carry a heavy, white-hot crucible.

- If your primary focus is ultimate precision and indoor work: An electric induction furnace provides unparalleled temperature control and safety by eliminating open flames and combustion byproducts, though at a significantly higher cost.

By understanding these core principles, you transform melting metal from a daunting task into a controlled and repeatable process.

Summary Table:

| Key Factor | Why It Matters |

|---|---|

| Crucible Material | Must withstand extreme heat and resist chemical reaction with the molten metal. |

| Furnace Type | Determines how metal is poured (lift-out, tilting, or bale-out) and impacts safety. |

| Fuel Source | Propane, electricity, or coke affects cost, control, and workspace requirements. |

| Proper PPE | Essential for protection from heat, splashes, and fumes (face shield, gloves, apron). |

| Thermal Shock Prevention | Gradual heating prevents the crucible from cracking. |

| Moisture Control | Eliminates the risk of a catastrophic steam explosion. |

Ready to build a safe and efficient metal melting setup for your lab? KINTEK specializes in high-performance lab equipment, including crucibles and furnaces designed for precise temperature control and operator safety. Our experts can help you select the perfect system for your specific metals and workflow. Contact KINTEK today to discuss your laboratory melting needs!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- What factors influence the general design of a tube furnace? Match Your Process with the Perfect System

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis