To press wood pellets, you must force pulverized raw wood material through a specialized metal plate, known as a die, using a high-pressure press. This process combines immense mechanical pressure with friction-generated heat, which activates the natural lignin within the wood. This lignin acts as a glue, binding the compressed particles together into the dense, uniform pellets that emerge from the die.

The critical insight is that pelletizing is not just a matter of force. It is a controlled process where the material's particle size, moisture content, and the heat generated during compression are managed precisely to create a durable, high-quality fuel.

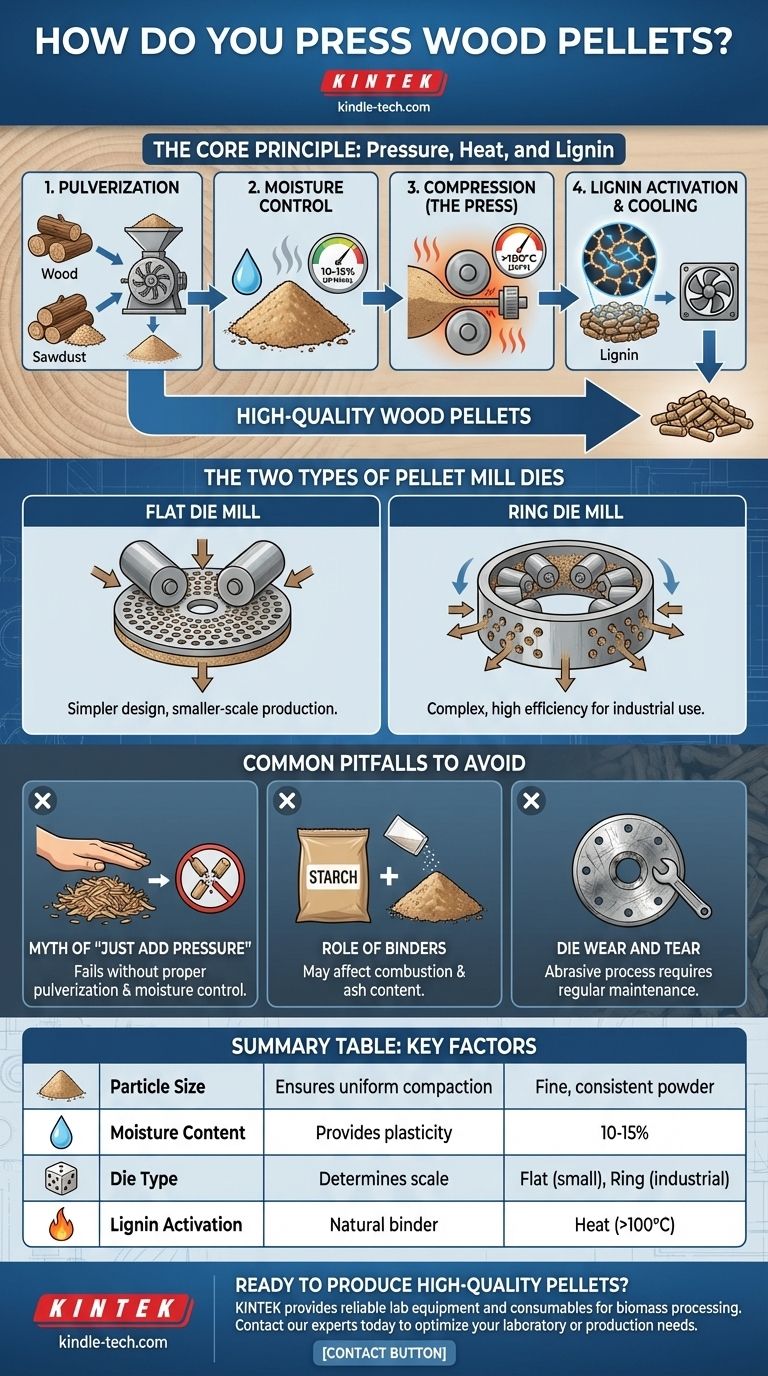

The Core Principle: Pressure, Heat, and Lignin

Creating a wood pellet is a transformation of raw biomass into a densified fuel. This transformation hinges on preparing the material correctly before it ever enters the press.

From Raw Wood to Consistent Powder

The process begins with pulverization. Raw wood materials like sawdust, shavings, or chips are ground down in a hammer mill to a consistent, fine powder.

This uniformity is essential. If particles are too large, they won't compact properly, leading to weak or inconsistent pellets.

The Critical Role of Moisture Content

Before pressing, the wood powder must have an optimal moisture content, typically between 10% and 15%.

Material that is too wet will create steam pockets in the die, preventing proper binding. Material that is too dry lacks the plasticity needed for compression and can result in brittle, crumbly pellets.

How Pressure Creates the Pellet

The prepared wood powder is fed into a pellet mill. Inside, rollers press the powder with extreme force, pushing it through the small holes of a die.

This compression squeezes the material into the familiar cylindrical pellet shape.

Lignin: The Wood's Natural Glue

The immense friction from this compression process generates significant heat, often reaching well over 100°C (212°F).

This heat softens the lignin, a natural polymer found in the wood's cell walls. The softened lignin acts as a natural binder, coating and gluing the wood particles together. As the pellets exit the die and cool, the lignin re-hardens, giving the pellet its rigid, durable structure.

The Two Types of Pellet Mill Dies

The die is the heart of the pellet mill, and its design dictates the machine's scale and efficiency.

The Flat Die Mill

In a flat die mill, the die is a horizontal, perforated disc. Rollers move across the top of this disc, forcing the raw material down through the holes.

This design is mechanically simpler and is most common in smaller-scale or entry-level pellet production.

The Ring Die Mill

A ring die mill uses a vertical, rotating ring lined with holes on its inner circumference. Rollers on the inside of the ring press the material outward through the holes.

This design is more complex but offers greater efficiency, durability, and throughput, making it the standard for industrial and large-scale commercial pellet manufacturing.

Common Pitfalls to Avoid

Achieving high-quality pellets requires avoiding common misconceptions and understanding the trade-offs.

The Myth of "Just Add Pressure"

Simply applying pressure to wood shavings is not enough. Without proper pulverization to a consistent size and precise moisture control, the pelletizing process will fail, resulting in poor-quality output or damage to the machinery.

The Role of Binders

While high-quality wood pellets rely on natural lignin, some biomass materials with low lignin content may require a forming agent or binder, such as starch.

Using binders can affect the combustion properties and ash content of the final pellet, which is a key consideration for fuel quality standards.

Die Wear and Tear

The pelletizing process is extremely abrasive. The die and rollers are consumable parts that are subject to constant wear. Regular maintenance and eventual replacement are necessary costs of operation.

Making the Right Choice for Your Goal

The right equipment and focus depend entirely on your objective.

- If your primary focus is small-scale or hobby production: A flat die mill is a more accessible and cost-effective starting point.

- If your primary focus is high-volume, commercial production: A ring die mill is the industry standard, providing the necessary efficiency and durability for consistent output.

- If your primary focus is ultimate pellet quality: Success depends on meticulously controlling your material preparation—particle size and moisture content—long before it reaches the press.

Ultimately, creating a superior wood pellet is a precise balance of material science and powerful mechanical force.

Summary Table:

| Key Factor | Role in Pelletizing | Optimal Range/Type |

|---|---|---|

| Particle Size | Ensures uniform compaction | Fine, consistent powder |

| Moisture Content | Provides plasticity for binding | 10-15% |

| Die Type | Determines scale and efficiency | Flat die (small-scale), Ring die (industrial) |

| Lignin Activation | Natural binder for pellet durability | Softened by friction heat (>100°C) |

Ready to produce high-quality wood pellets with precision? KINTEK specializes in reliable lab equipment and consumables for biomass processing, including pellet mills and material preparation tools. Whether you're scaling up production or optimizing pellet quality, our solutions ensure consistent results. Contact our experts today to find the perfect equipment for your laboratory or production needs!

Visual Guide

Related Products

- Twin Screw Extruder Plastic Granulation Machine

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Laboratory Heat Press Machine

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

People Also Ask

- What is the meaning of blowing film? A Guide to Biaxial Orientation and Stronger Plastic Films

- What is the screw extrusion process? A Guide to Continuous Plastic Profiling

- How does extrusion work step by step? A Guide to the Continuous Manufacturing Process

- What is the difference between extrusion and co-extrusion? Engineer Multi-Material Parts

- What are the disadvantages of the extrusion process? High Costs and Geometric Limits Explained