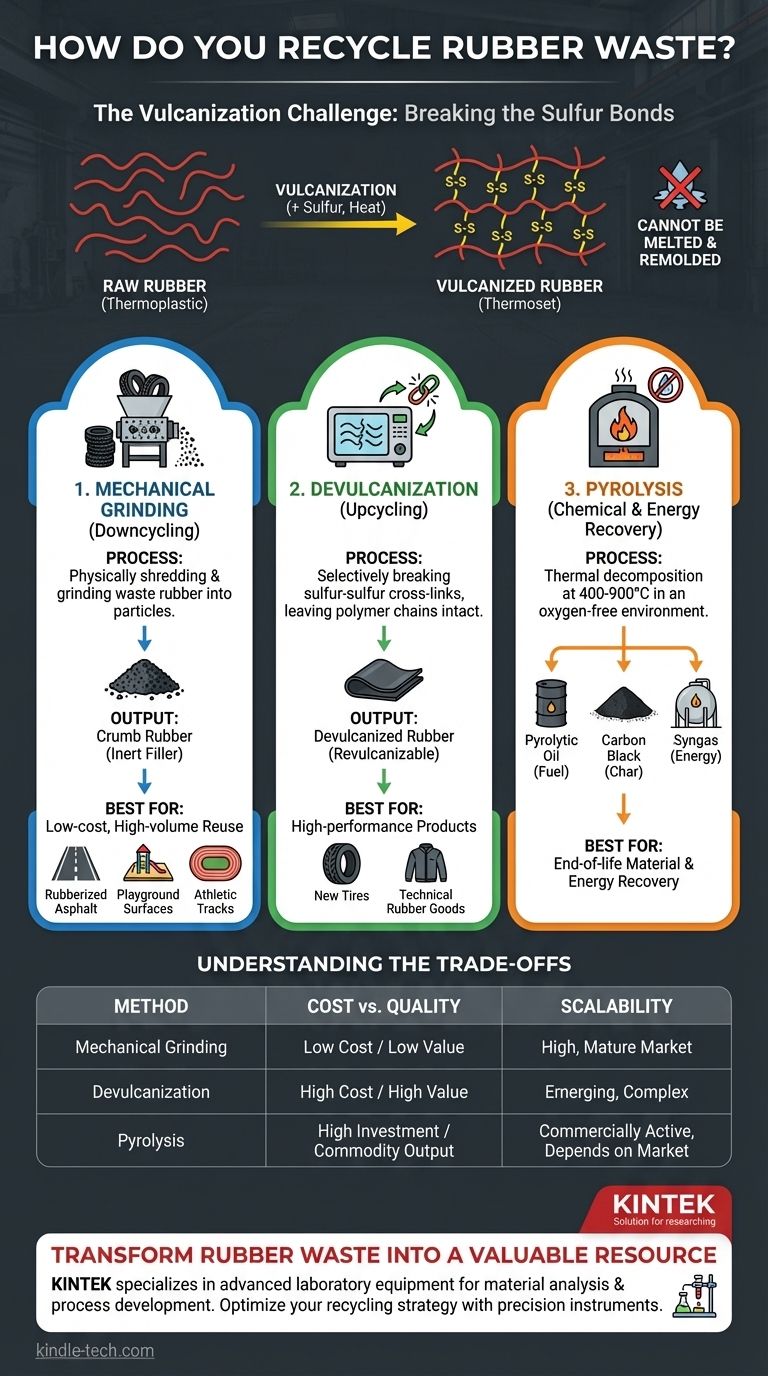

Recycling rubber waste is fundamentally different from recycling plastic due to its chemical structure. The primary methods are not simple melting and remolding but instead involve mechanical grinding, advanced chemical devulcanization, or thermal decomposition through pyrolysis. Each of these processes targets a different outcome, from low-grade filler material to high-value chemical feedstocks.

The central challenge in rubber recycling isn't just breaking it down, but reversing the chemical "vulcanization" process that gives it its strength and elasticity. While simple mechanical grinding is common, true closed-loop recycling requires advanced techniques to break the sulfur bonds without destroying the underlying polymer, a far more complex task than recycling common plastics.

The Vulcanization Problem: Why Rubber is So Hard to Recycle

Before exploring the methods, it's critical to understand why rubber, particularly tire rubber, presents a unique challenge. The issue lies in a process called vulcanization.

What is Vulcanization?

Vulcanization is a chemical process that uses sulfur to create strong cross-links between long polymer chains in the rubber. Imagine turning a pile of loose spaghetti strands (raw rubber) into a single, interconnected fishing net (vulcanized rubber).

This network of cross-links gives rubber its signature properties: strength, elasticity, and durability. It also transforms the material into a thermoset, meaning that once it's cured, it cannot be simply melted and reshaped like a thermoplastic.

The Recycling Dilemma

When you heat a thermoset material like vulcanized rubber, it doesn't melt into a liquid. Instead, it maintains its shape until it reaches a temperature where it begins to degrade and burn.

This means that traditional melt-and-remold recycling methods used for many plastics are completely ineffective for the vast majority of rubber waste. Effective recycling must either work around the cross-links or find a way to break them.

Primary Rubber Recycling Methods Explained

There are three main pathways for processing rubber waste, each with distinct goals, processes, and outputs.

Method 1: Mechanical Grinding (Downcycling)

This is the most common and straightforward method. It involves physically shredding and grinding waste rubber, primarily from tires, into small particles of various sizes, often called crumb rubber.

The vulcanized cross-links remain intact in these particles. As a result, crumb rubber acts as an inert filler material rather than a functional rubber. It's often used in low-spec applications like rubberized asphalt, playground surfaces, athletic tracks, and molded flooring.

Method 2: Devulcanization (Upcycling)

Devulcanization is the "holy grail" of rubber recycling. The goal is to selectively break the sulfur-sulfur cross-links created during vulcanization while leaving the main carbon polymer chains intact.

This is a highly technical process that can use various technologies, including microwaves, ultrasonic waves, or chemical agents. If successful, the resulting devulcanized rubber can be re-vulcanized and blended with virgin rubber to manufacture new, high-performance products, including tires.

Method 3: Pyrolysis (Chemical & Energy Recovery)

Pyrolysis is a thermal decomposition process. Rubber is heated to high temperatures (400-900°C) in an oxygen-free environment, causing the complex polymers to break down into simpler, valuable substances.

This process doesn't "recycle" the rubber in a circular sense but instead recovers its core components. The primary outputs are:

- Pyrolytic Oil: A synthetic crude oil that can be refined into diesel or other fuels.

- Carbon Black (Char): A solid residue that can be used as a pigment, reinforcing agent in new rubber, or as a solid fuel.

- Syngas: A mixture of combustible gases that can be used to power the pyrolysis process itself.

Understanding the Trade-offs

Choosing a recycling method involves balancing cost, output quality, and environmental impact. There is no single "best" solution; the right choice depends entirely on the end goal.

Cost vs. Quality

Mechanical grinding has the lowest capital and operational costs but produces the lowest-value product (crumb rubber).

Devulcanization is technically complex and often more expensive, but it yields a high-value material that can directly substitute for virgin rubber.

Pyrolysis requires a significant initial investment in equipment but creates multiple streams of marketable commodities (oil, carbon, gas), offering a different economic model.

Scalability and Viability

Mechanical grinding is mature, widely implemented, and commercially viable on a global scale. The market for crumb rubber is well-established.

Devulcanization technologies are still emerging. While commercially available, they are not yet deployed at the same massive scale as grinding, often facing challenges in consistency and cost-competitiveness.

Pyrolysis is commercially active, particularly for end-of-life tires. Its viability depends heavily on the market prices for oil and carbon black, as well as the ability to secure a large, consistent supply of feedstock.

Making the Right Choice for Your Goal

To select the appropriate pathway, you must first define your objective for the waste stream.

- If your primary focus is low-cost, high-volume reuse: Mechanical grinding to produce crumb rubber for applications like asphalt, playgrounds, or filler is your most viable option.

- If your primary focus is creating a high-performance recycled material: Devulcanization is the only path to producing a material that can be blended back into new, high-spec rubber products.

- If your primary focus is end-of-life material recovery and energy: Pyrolysis breaks the rubber down into valuable oil, gas, and carbon char, avoiding landfills entirely.

Understanding these distinct pathways is the key to transforming rubber waste from a liability into a valuable technical resource.

Summary Table:

| Method | Process | Output Material | Best For |

|---|---|---|---|

| Mechanical Grinding | Shredding & grinding | Crumb rubber (filler) | Low-cost, high-volume reuse (e.g., asphalt, playgrounds) |

| Devulcanization | Breaking sulfur bonds chemically/thermally | Revulcanizable rubber | High-performance recycled products (e.g., new tires) |

| Pyrolysis | Thermal decomposition without oxygen | Oil, carbon black, syngas | End-of-life material & energy recovery |

Ready to transform your rubber waste into a valuable resource?

Choosing the right recycling method is critical for efficiency, cost, and environmental impact. At KINTEK, we specialize in advanced laboratory equipment for material analysis and process development, helping you optimize your rubber recycling strategy.

Whether you're researching devulcanization techniques or scaling up pyrolysis processes, our precision instruments provide the data and reliability you need to succeed.

Contact our experts today to discuss how KINTEK's solutions can support your rubber recycling goals.

Get in touch via our Contact Form for a personalized consultation.

Visual Guide

Related Products

- Lab Internal Rubber Mixer Rubber Kneader Machine for Mixing and Kneading

- Laboratory Hybrid Tissue Grinding Mill

- Laboratory High Throughput Tissue Grinding Mill Grinder

- Powerful Plastic Crusher Machine

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- What are the advantages of twin screw extruder? Superior Mixing, Flexibility & Efficiency

- What is a two roll mill? Master Polymer Mixing for R&D and Quality Control

- What do injection molding machines make? Mass-Producing the Plastic Parts in Your Life

- How to make compound rubber? Master the Sequence to Prevent Scorch and Ensure Quality

- What is the process of double extrusion? Create Integrated Multi-Material Components

- How many types of mixers are there? Find the Right Mixing Mechanism for Your Material

- What are the advantages of screw extruders? Achieve Efficient, Continuous Polymer Processing

- What is the blown film technique? A Guide to High-Strength Plastic Film Production