Sintering tungsten carbide is a precise, multi-stage heating process that transforms a compacted powder into a fully dense, high-performance material. The process involves heating a "green" part—a fragile compact of tungsten carbide (WC) grains and a metallic binder like cobalt—in a controlled furnace until the binder melts, fills the voids, and fuses the structure into a solid mass upon cooling.

Sintering is often viewed as a single heating step, but its success is entirely dependent on the preceding stages of powder metallurgy. True control over the final product's properties—its hardness, toughness, and wear resistance—is achieved by understanding the entire journey from raw powder to finished part.

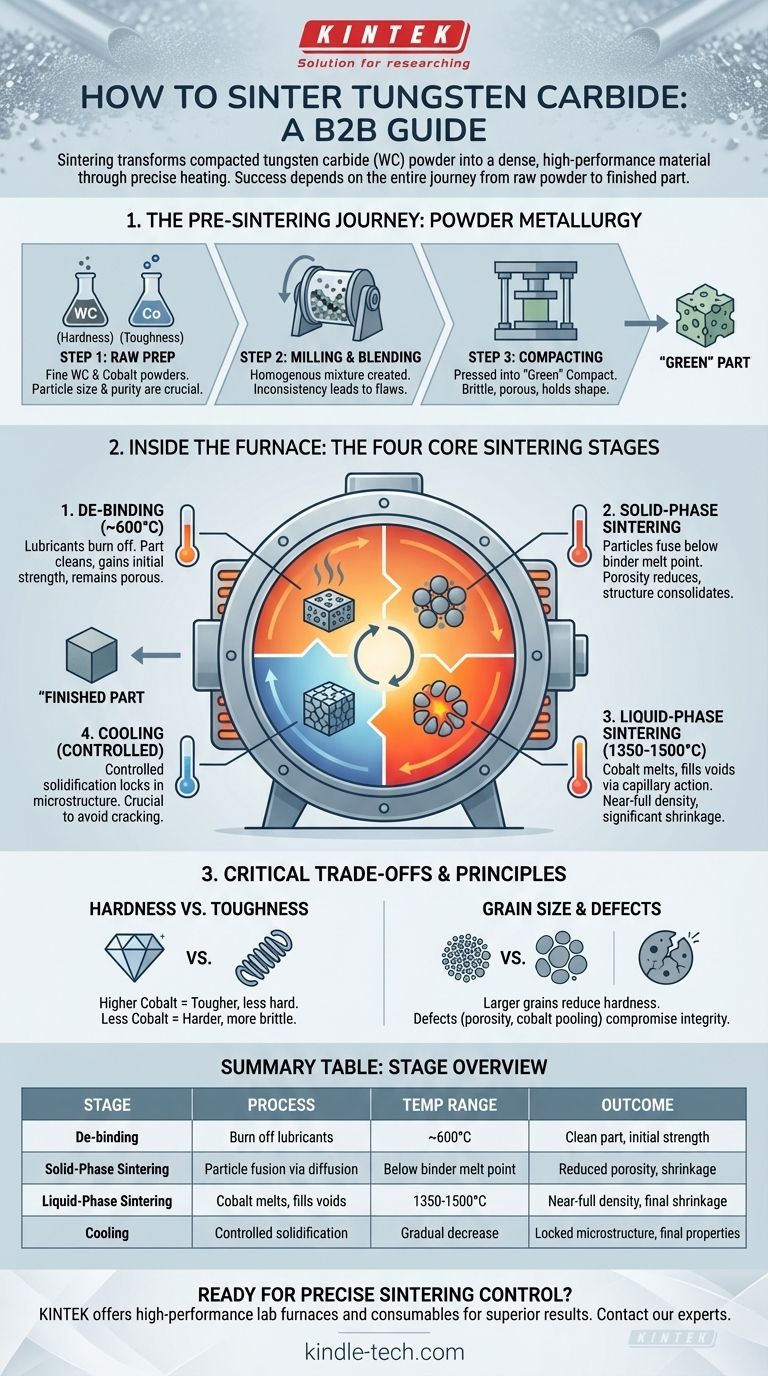

The Broader Context: Powder Metallurgy

Before a part ever enters a sintering furnace, it undergoes several critical preparation stages. The final quality is determined here.

Step 1: Raw Material Preparation

The process begins with extremely fine powders. Typically, this is a combination of tungsten carbide (WC), which provides the hardness, and a cobalt (Co) binder, which provides toughness.

The particle size and purity of these initial powders are paramount, as they directly influence the final microstructure and performance of the sintered part.

Step 2: Milling and Blending

The WC and Co powders are mixed together, often with a pressing lubricant, in a process called milling.

The goal is to create a perfectly homogenous mixture. Any inconsistency in this blend will result in flaws, inconsistent density, and poor performance in the final product.

Step 3: Compacting the "Green" Part

This homogenous powder is then pressed into the desired shape using immense pressure.

This resulting object is known as a "green" compact. It is brittle and porous but holds its shape, ready for the transformational heat of the sintering furnace.

Inside the Furnace: The Four Core Sintering Stages

With the "green" part formed, the sintering process itself begins. This happens inside a vacuum or controlled-atmosphere furnace to prevent oxidation.

Stage 1: De-binding and Pre-Sintering

As the temperature slowly rises (typically to around 600°C), the pressing lubricants and any other molding agents are burned off.

This stage cleans the material and creates pathways for gases to escape. The part gains some initial strength but is still highly porous.

Stage 2: Solid-Phase Sintering

As the heat increases further but remains below the binder's melting point, the particles begin to fuse at their points of contact.

This process, driven by atomic diffusion, starts to shrink the part and reduce porosity. The structure becomes more consolidated, but significant voids remain.

Stage 3: Liquid-Phase Sintering

This is the most critical stage. The temperature is raised above the melting point of the cobalt binder (around 1350-1500°C).

The now-liquid cobalt acts like a solvent, flowing into the remaining voids through capillary action. It pulls the solid tungsten carbide grains together, eliminating nearly all porosity and causing significant shrinkage of the part.

Stage 4: Cooling

The part is cooled in a highly controlled manner. This is crucial for solidifying the cobalt matrix around the WC grains without inducing thermal shock or cracking.

The final microstructure, and thus the material's properties, are locked in during this final stage.

Understanding the Critical Trade-offs

The parameters of the sintering cycle are a constant balance of competing properties.

Hardness vs. Toughness

The ratio of tungsten carbide to cobalt is the primary determinant of the material's final characteristics.

A higher cobalt content results in a tougher, more impact-resistant material, but at the expense of hardness and wear resistance. Conversely, less cobalt means a harder but more brittle material.

Grain Size Control

Sintering for too long or at too high a temperature can cause the tungsten carbide grains to grow larger.

Larger grains generally reduce hardness and wear resistance. Additives known as grain growth inhibitors are often used to maintain a fine microstructure during liquid-phase sintering.

Sintering Defects

An improperly controlled process can lead to critical flaws. These include porosity (incomplete densification), cobalt pooling (uneven distribution of the binder), or internal cracking.

These defects compromise the structural integrity of the part and are often caused by poor initial blending, incorrect heating rates, or a contaminated furnace atmosphere.

Applying Sintering Principles to Your Goal

The ideal sintering process is defined by the intended application of the final part.

- If your primary focus is maximum wear resistance and hardness: You will aim for a lower cobalt content and a fine tungsten carbide grain size, requiring meticulous control over sintering time and temperature to prevent grain growth.

- If your primary focus is impact resistance and toughness: You will formulate with a higher cobalt content, as the ductile cobalt matrix is what absorbs energy and prevents fracture.

- If your primary focus is overall quality and consistency: Your control over initial powder purity, blending homogeneity, and a clean furnace atmosphere is more critical than any single sintering parameter.

Ultimately, mastering the sintering of tungsten carbide is about using heat and a controlled atmosphere to transform a fragile powder compact into a fully dense, exceptionally strong component.

Summary Table:

| Sintering Stage | Key Process | Temperature Range | Outcome |

|---|---|---|---|

| De-binding | Burn off lubricants | ~600°C | Clean part, initial strength |

| Solid-Phase Sintering | Particle fusion via diffusion | Below binder melt point | Reduced porosity, shrinkage |

| Liquid-Phase Sintering | Cobalt melts, fills voids | 1350-1500°C | Near-full density, final shrinkage |

| Cooling | Controlled solidification | Gradual decrease | Locked microstructure, final properties |

Ready to achieve precise control over your tungsten carbide sintering process? KINTEK specializes in high-performance lab furnaces and consumables designed for exacting powder metallurgy applications. Our equipment ensures uniform heating, controlled atmospheres, and reliable results for superior material properties. Contact our experts today to discuss how we can support your laboratory's sintering needs and enhance your product quality.

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

People Also Ask

- How does a high-temperature furnace system assist in metal deposition? Master Steam Activation & Metal Migration

- What is the minimum pressure in a vacuum chamber? Achieve Your Application's Ideal Vacuum

- What is the function of a vacuum infiltration furnace in Cf/SiC composites? Master Reactive Melt Infiltration

- What role do vacuum pumps and pressure control systems play in studying the oxidation reactions of metallic yttrium?

- What are acceptable methods of leak detection? Ensure Your System's Integrity with the Right Method

- What does sintering do? Transform Powder into Strong, Dense Components

- What is physical Vapour deposition in crystal growth? Master Atomic-Level Thin Film Fabrication

- Why does copper-based porous foil as an interlayer in vacuum diffusion welding result in base-metal strength joints?