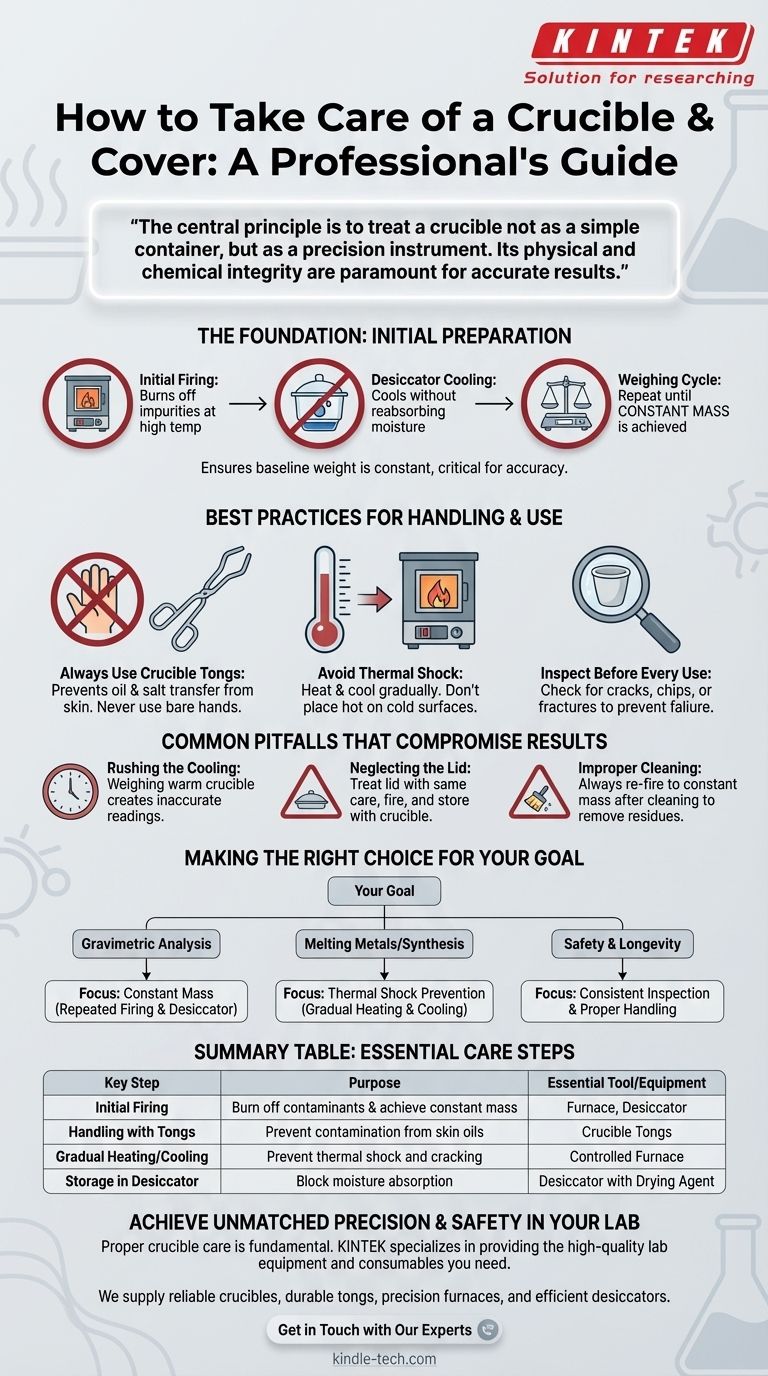

Proper crucible and cover care is a systematic process focused on maintaining a constant, uncontaminated mass and preventing structural failure. The core steps involve an initial firing to remove impurities, meticulous handling with tongs to avoid transferring oils, gradual heating and cooling to prevent cracking, and storage in a desiccator to block moisture absorption.

The central principle is to treat a crucible not as a simple container, but as a precision instrument. Its physical and chemical integrity are paramount for achieving accurate, repeatable results in high-temperature applications.

The Foundation: Initial Preparation

Before a crucible can be used for any sensitive measurement, it must be brought to a stable, clean state. This initial preparation is the most critical phase for ensuring accuracy.

Why Initial Firing is Non-Negotiable

A new crucible contains moisture, dust, and residual chemicals from manufacturing. Initial firing (also called ignition) burns off these volatile contaminants at a high temperature.

This process establishes a constant mass—a baseline weight that will not change with subsequent heatings, ensuring that any change in mass during your experiment is due to your sample alone.

The Firing and Weighing Cycle

To prepare the crucible, heat it in a furnace to the working temperature of your experiment (or slightly higher) for at least 15-20 minutes.

After heating, use clean tongs to move the hot crucible and lid to a desiccator. This is a sealed container with a drying agent that allows the crucible to cool to room temperature without reabsorbing atmospheric moisture.

Once cool, weigh the crucible on an analytical balance. Repeat the entire cycle of heating, cooling in the desiccator, and weighing until two consecutive measurements are identical. This confirms you have achieved constant mass.

Best Practices for Handling and Use

How you handle the crucible during an experiment is just as important as its initial preparation. Simple mistakes can easily invalidate your results.

Always Use Crucible Tongs

Never touch a crucible with your bare hands. The oils, salts, and moisture from your skin will transfer to its surface, altering its mass and compromising quantitative measurements.

Crucible tongs are the only tool you should use to move or handle a crucible, whether it is hot or at room temperature. Ensure the tongs themselves are clean.

Avoid Thermal Shock

Crucibles are typically made of ceramic materials that are strong under compression but vulnerable to thermal shock. This occurs when the temperature changes too rapidly, causing stress that leads to cracks or shattering.

Always heat and cool your crucible gradually. Place a cold crucible in a cool furnace and ramp up the temperature slowly. Similarly, avoid placing a hot crucible on a cold lab bench; let it cool partially in the air before moving it to a desiccator.

Inspect Before Every Use

Before each use, perform a quick visual inspection. Look for small cracks, chips, or fractures. A compromised crucible can fail catastrophically at high temperatures, resulting in the complete loss of your sample and potential damage to the furnace.

Common Pitfalls That Compromise Results

Avoiding common mistakes is key to maintaining the crucible's integrity and the validity of your data.

Rushing the Cooling Process

Removing the crucible from the desiccator before it has returned to ambient temperature is a frequent error. A warm crucible will create air currents around the balance pan, leading to an inaccurate, unstable mass reading.

Neglecting the Lid

The lid should be treated with the same care as the crucible itself. It should be fired, handled with tongs, and stored in the desiccator alongside the crucible. For many procedures, the crucible and lid are kept slightly ajar during heating to allow gases to escape.

Improper Cleaning

After use, most residue can be removed by re-firing the crucible. For stubborn materials, careful mechanical removal or specific chemical cleaning may be necessary. Always follow a cleaning procedure by firing the crucible to constant mass again to ensure all cleaning agents are removed.

Making the Right Choice for Your Goal

Your specific objective dictates which aspect of crucible care is most critical.

- If your primary focus is gravimetric analysis: Your top priority is achieving and maintaining a precise constant mass through repeated firing, desiccator cooling, and exclusive use of tongs.

- If your primary focus is melting metals or synthesis: Your main concern is preventing thermal shock through gradual heating/cooling and ensuring the crucible material is chemically compatible with your sample.

- If your primary focus is safety and equipment longevity: Your guiding principle is consistent pre-use inspection for cracks and strict adherence to proper handling procedures to prevent breakage.

Adopting these disciplined practices ensures your crucible remains a reliable tool for accurate scientific work.

Summary Table:

| Key Step | Purpose | Essential Tool/Equipment |

|---|---|---|

| Initial Firing | Burn off contaminants & achieve constant mass | Furnace, Desiccator |

| Handling with Tongs | Prevent contamination from skin oils | Crucible Tongs |

| Gradual Heating/Cooling | Prevent thermal shock and cracking | Controlled Furnace |

| Storage in Desiccator | Block moisture absorption | Desiccator with Drying Agent |

Achieve Unmatched Precision and Safety in Your Lab

Proper crucible care is fundamental to the accuracy and safety of your high-temperature procedures, from gravimetric analysis to metal synthesis. KINTEK specializes in providing the high-quality lab equipment and consumables you need to master these techniques.

We supply reliable crucibles, durable tongs, precision furnaces, and efficient desiccators designed for consistent performance. Let our expertise help you enhance your lab's efficiency and data integrity.

Contact us today to find the perfect tools for your specific application and ensure your crucible care routine is flawless.

Visual Guide

Related Products

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

People Also Ask

- Why is a graphite crucible selected for Na2S-NPS-C composites? Ensure High Purity in Casting-Annealing Processes

- Why must aluminum alloys be heated in alumina crucibles? Ensure Pure Results in Molten Corrosion Experiments

- Can you overheat a crucible? Avoid Catastrophic Failure and Extend Crucible Life

- What are the requirements for reaction crucibles used in the CT method? Ensuring Coating Purity and Stability

- Why is a Rhodium-Platinum (Rh-Pt) crucible preferred over a standard ceramic crucible? Achieve Purity in Glass Melting

- What are high melting point crucibles? Essential for Extreme Heat Applications

- How long do crucibles last? Extend crucible lifespan from 15 to 100+ uses

- Can you melt different metals in the same crucible? Avoid Costly Contamination and Failed Castings