In short, a larger area decreases the pressure exerted by the same force. The relationship is inversely proportional: as the area over which a constant force is applied increases, the pressure at any given point on that surface goes down. This is because the same amount of force is being spread out over a wider surface.

The core principle to understand is that pressure is not force itself, but the concentration of force. By increasing the area of contact, you are effectively diluting the force, leading to a reduction in pressure.

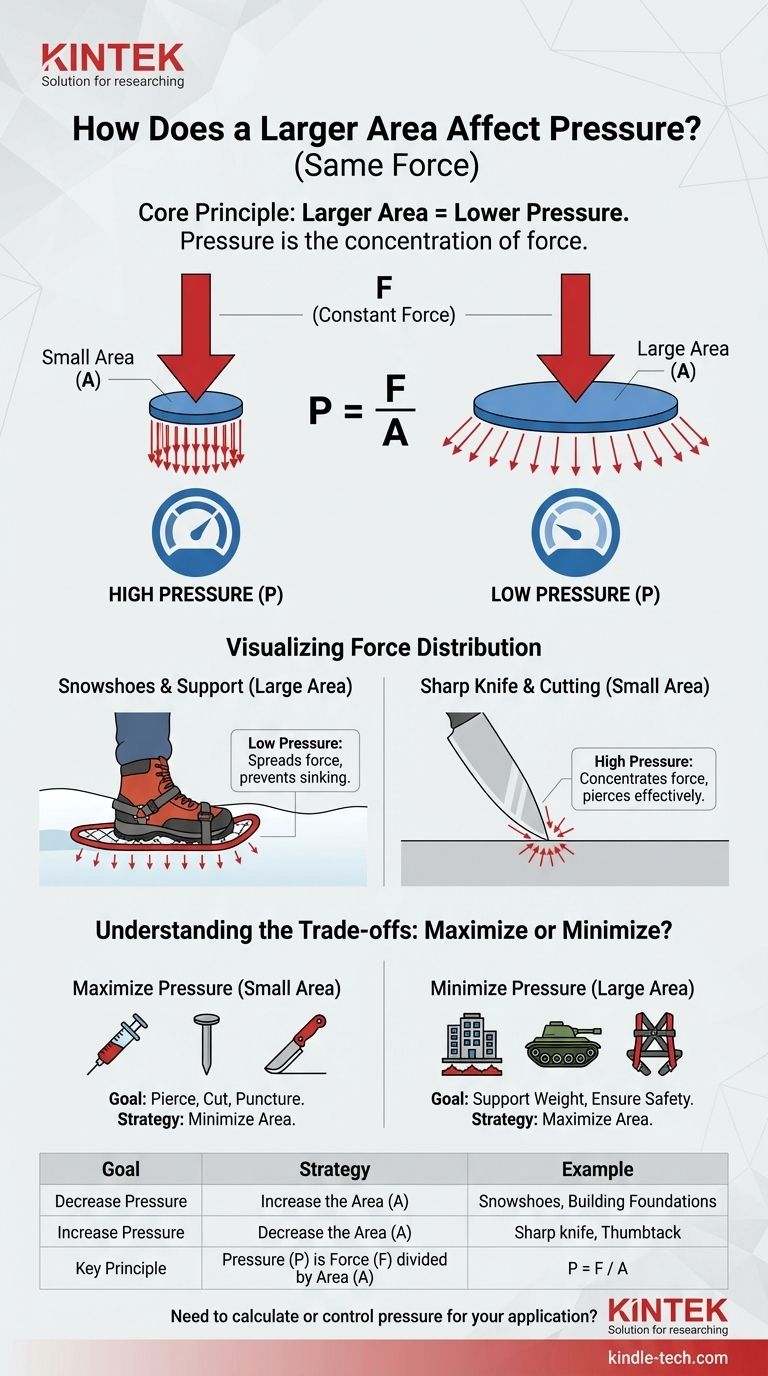

The Fundamental Relationship: Pressure, Force, and Area

To truly grasp this concept, we must look at the simple but powerful physics behind it. The interplay between these three elements governs everything from how a knife cuts to how a building stands.

The Core Equation

The relationship is defined by the equation P = F / A.

- P stands for Pressure, which is the amount of force exerted per unit of area.

- F stands for Force, which is the push or pull on an object (like weight).

- A stands for Area, which is the surface over which the force is distributed.

This formula makes it clear that if the Force (F) remains constant, increasing the Area (A) in the denominator will inevitably cause the resulting Pressure (P) to decrease.

An Intuitive Analogy: A Bed of Nails

Imagine trying to stand on a single nail. Your entire body weight (the force) would be concentrated on the tiny point of that one nail, creating immense pressure that would easily puncture your foot.

Now, picture a bed of thousands of nails. When you lie down, your same body weight is now distributed evenly across the points of all those nails. The total area is huge, so the pressure from any single nail is incredibly small and not enough to break your skin. The force didn't change, but the area did, radically changing the outcome.

Visualizing Force Distribution

Think of force as a fixed amount of water and area as the container you pour it into.

If you pour the water into a tall, thin glass (a small area), the water level will be high (high pressure). If you pour that same amount of water into a wide, shallow pan (a large area), the water level will be very low (low pressure). The amount of water never changed, only its concentration.

Practical Examples in Everyday Life

This principle is not just theoretical; it is a fundamental aspect of engineering and design that you interact with constantly.

Why Snowshoes Work

A person's weight (force) is constant. When wearing a normal boot, that force is concentrated on the small area of the sole, causing you to sink into the snow. Snowshoes dramatically increase the surface area, distributing your weight and lowering the pressure far below what the snow can support.

The Sharpness of a Knife

A sharp knife has an extremely small surface area on its cutting edge. This design concentrates the force you apply, creating immense pressure that can easily slice through materials. A dull knife has a larger, blunted area, which spreads the force out and requires much more effort to achieve the same cutting pressure.

Foundations of Buildings

Skyscrapers are incredibly heavy. To prevent them from sinking into the ground, they are built on wide, massive concrete foundations. These foundations spread the building's immense weight (force) over a very large area, ensuring the pressure exerted on the soil is low enough to be safely supported.

Thumbtacks and Needles

A thumbtack is a perfect example of manipulating this principle. It has a large, flat head for your thumb (large area, low pressure for comfort) and a sharp, tiny point for the wall (small area, high pressure for easy piercing).

Understanding the Trade-offs

The goal isn't always to decrease pressure. The optimal design depends entirely on the intended function, and engineers must choose whether to concentrate or distribute force.

When High Pressure is the Goal

In many applications, the objective is to maximize pressure. This is achieved by minimizing the area of contact to concentrate the applied force.

Examples include injection needles, nails, cutting tools, and ice skates. The entire purpose of these designs is to create pressure high enough to pierce a surface with minimal force.

When Low Pressure is Critical

Conversely, minimizing pressure is often a matter of safety, stability, or preservation. This is achieved by maximizing the area of contact.

Examples include the wide treads on a tank or bulldozer, the broad straps on a heavy backpack, and safety harnesses that distribute the force of a fall across the torso.

Making the Right Choice for Your Goal

Understanding how to manipulate the relationship between force, pressure, and area is key to solving countless physical challenges.

- If your primary focus is to pierce, cut, or puncture: You must concentrate your force by making the contact area as small as possible.

- If your primary focus is to support weight or prevent sinking: You must distribute your force by making the contact area as large as possible.

- If your primary focus is to ensure safety during an impact: You must dissipate the force across the widest possible area to minimize pressure on any single point.

Mastering this single principle allows you to design and build more effective tools and safer structures.

Summary Table:

| Goal | Strategy | Example |

|---|---|---|

| Decrease Pressure | Increase the Area (A) | Snowshoes, building foundations |

| Increase Pressure | Decrease the Area (A) | Sharp knife, thumbtack, ice skate blade |

| Key Principle | Pressure (P) is Force (F) divided by Area (A) | P = F / A |

Need to calculate or control pressure for your application? KINTEK specializes in lab equipment and consumables, providing the tools and expertise to help you apply these fundamental principles in your research or quality control processes. Whether you're designing a new product or optimizing a procedure, our team can help you select the right equipment to measure and manage force and pressure accurately.

Contact our experts today to discuss your specific needs!

Visual Guide

Related Products

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

People Also Ask

- What are the advantages of centrifugation over filtration? Handle Challenging Samples with Ease

- What is sintering aluminum? A guide to high-volume, complex part manufacturing

- What is heat treatment for small parts? Achieve Superior Strength and Durability

- How can we reduce the toxicity of carbon nanotubes? Strategies for Safer Applications

- How does temperature affect the mechanical properties of materials? Avoid Brittle Fracture & Creep Failure

- How does a high-power ultrasonic homogenizer assist in the preparation of organic-inorganic nanocomposites?

- What is abnormal grain growth during sintering? Understanding a Key Microstructural Defect

- What is glass sintering? A Guide to Low-Temperature, High-Strength Glass Fabrication