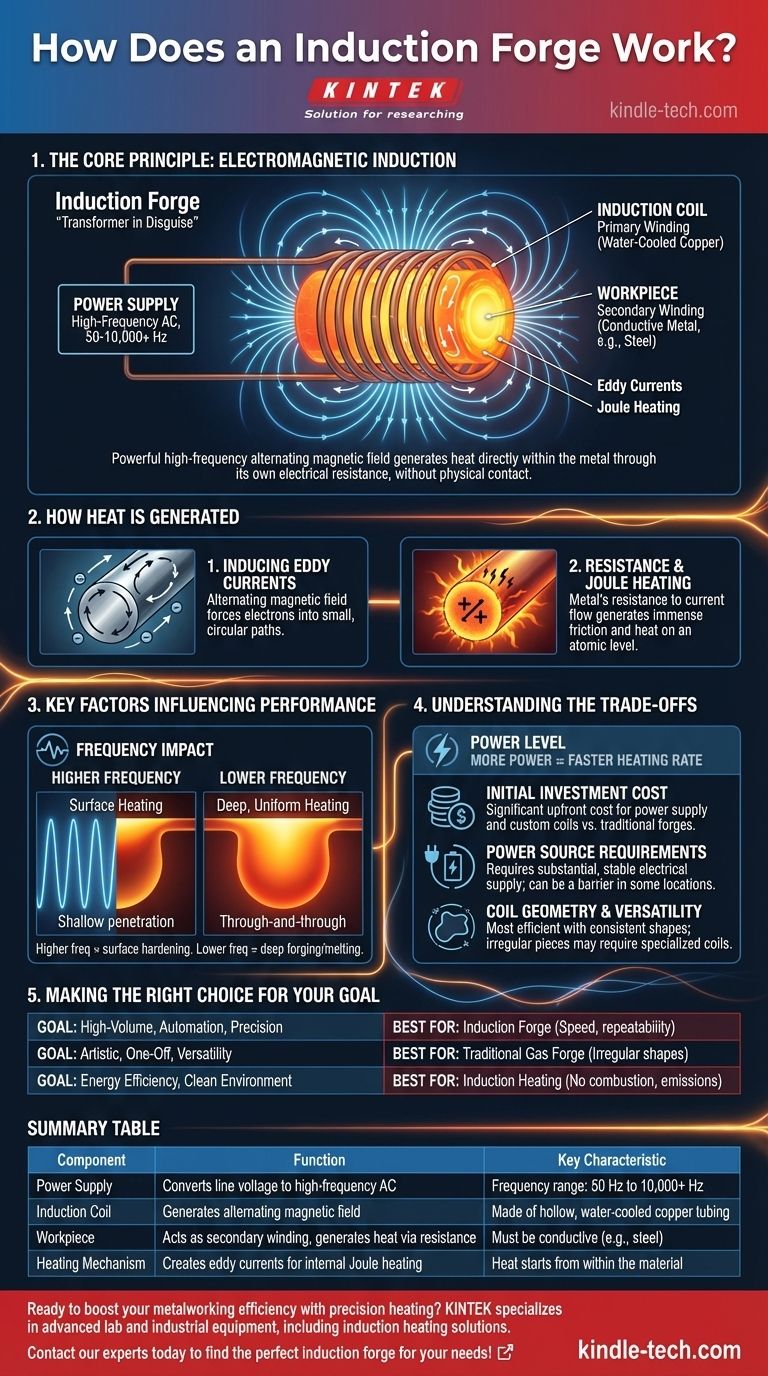

At its core, an induction forge works by using a powerful, high-frequency alternating magnetic field to generate heat directly within a metal workpiece, without any physical contact or flame. This process, known as electromagnetic induction, creates internal electrical currents that produce intense and rapid heating through the metal's own electrical resistance.

An induction forge operates like a specialized transformer where the forge's copper coil is the primary winding and the metal workpiece itself becomes a short-circuited secondary winding. The rapidly changing magnetic field induces powerful electrical currents (eddy currents) within the metal, and the material's natural resistance to this current flow generates precise, controllable heat.

The Core Principle: A Transformer in Disguise

An induction forge leverages a fundamental law of physics: electromagnetism. The entire system is designed to turn a piece of conductive metal into its own heating element.

The Power Supply and Primary Coil

The system starts with a high-frequency power supply. This unit converts standard line voltage into a high-frequency alternating current, often ranging from 50 Hz to over 10,000 Hz.

This current is sent through a specially designed induction coil, which is typically made of hollow copper tubing so it can be water-cooled. This coil is the primary of our "transformer."

The Workpiece as the Secondary

When you place a conductive material like steel inside the coil, it becomes the secondary component. The alternating current in the coil generates a powerful and rapidly changing magnetic field around it.

This magnetic field penetrates the workpiece, inducing electrical currents within the metal.

How Heat Is Actually Generated

The magnetic field itself doesn't create the heat. It's the reaction of the workpiece to this field that generates thermal energy through two primary effects.

Inducing Eddy Currents

The primary heating mechanism comes from eddy currents. The alternating magnetic field forces electrons within the metal to flow in small, circular paths.

Resistance and Joule Heating

The metal has a natural resistance to the flow of these electrical currents. As the eddy currents fight against this resistance, they generate immense friction on an atomic level, which manifests as heat. This is known as Joule heating.

The result is incredibly fast and efficient heating that starts from within the material itself, rather than being applied from an external source.

Key Factors Influencing Performance

The effectiveness of an induction forge is not arbitrary; it's controlled by precise electrical parameters that determine how the metal heats.

The Impact of Frequency

The frequency of the alternating current is a critical variable. A higher frequency tends to concentrate the eddy currents near the surface of the workpiece, which is ideal for surface hardening.

A lower frequency allows the magnetic field to penetrate deeper into the metal, resulting in more uniform, through-and-through heating, which is better for forging or melting.

The Importance of Power

The power level (measured in kilowatts) determines the rate of heating. More power means more energy is transferred to the workpiece per second, allowing it to reach the target temperature much faster.

This direct relationship between power and heating speed makes induction forges highly efficient and productive.

Understanding the Trade-offs

While powerful, induction technology is not universally superior for every application. Its advantages come with specific limitations that must be considered.

Initial Investment Cost

Induction systems represent a significant upfront capital investment compared to traditional gas or coal forges. The power supply and custom coils are complex pieces of equipment.

Power Source Requirements

These forges require a substantial and stable electrical supply. In locations with limited or unreliable power infrastructure, this can be a major barrier to implementation.

Coil Geometry and Versatility

Heating is most efficient when the workpiece has a consistent shape that fits closely within the coil. Heating highly irregular or oversized pieces can be inefficient or require multiple, specialized coils, reducing the system's flexibility.

Making the Right Choice for Your Goal

Selecting a heating method depends entirely on your operational priorities.

- If your primary focus is high-volume production and automation: An induction forge is unparalleled due to its speed, precision, and the repeatable quality it delivers.

- If your primary focus is artistic or one-off blacksmithing: A traditional gas forge may offer greater versatility for irregular shapes and a lower initial investment.

- If your primary focus is energy efficiency and a clean work environment: Induction heating offers a significant advantage over the combustion and emissions of fossil fuel-based forges.

Understanding these core principles empowers you to select the heating technology that best aligns with your operational needs and long-term goals.

Summary Table:

| Component | Function | Key Characteristic |

|---|---|---|

| Power Supply | Converts line voltage to high-frequency AC | Frequency range: 50 Hz to 10,000+ Hz |

| Induction Coil | Generates alternating magnetic field | Made of hollow, water-cooled copper tubing |

| Workpiece | Acts as secondary winding, generates heat via resistance | Must be conductive (e.g., steel) |

| Heating Mechanism | Creates eddy currents for internal Joule heating | Heat starts from within the material |

Ready to boost your metalworking efficiency with precision heating? KINTEK specializes in advanced lab and industrial equipment, including induction heating solutions tailored for forging, hardening, and more. Our systems deliver rapid, controlled, and repeatable results, saving you time and energy while ensuring superior quality. Contact our experts today to find the perfect induction forge for your needs!

Visual Guide

Related Products

- Non Consumable Vacuum Arc Induction Melting Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Gold Disc Electrode

People Also Ask

- What is the primary function of a vacuum arc melting furnace in RHEA preparation? Achieving Extreme Thermal Fusion

- What is the primary function of vacuum melting equipment in Ti-Zr-Ni alloy preparation? Ensure Purity and Phase Stability

- What is the difference between VAR and VIM? Legacy Vimscript Variables vs. Modern Neovim API

- What are the advantages and disadvantages of brazing? A Guide to Strong, Clean Metal Joining

- How does vacuum arc melting equipment facilitate Ti-Cr-Al-Nb alloy prep? Precision High-Temp Melting Explained