An autoclave sterilizes equipment by using high-pressure steam to achieve temperatures far beyond the boiling point of water. This process of moist heat sterilization is exceptionally effective because the intense heat and penetrating steam work together to destroy all microbial life, including resilient bacterial spores and viruses, by irreversibly damaging their essential proteins and enzymes.

The fundamental challenge in sterilization is that boiling water at 100°C (212°F) is not hot enough to kill heat-resistant bacterial spores. An autoclave solves this by functioning like a sophisticated pressure cooker, using increased pressure to raise the boiling point of water, creating superheated steam that reliably sterilizes materials.

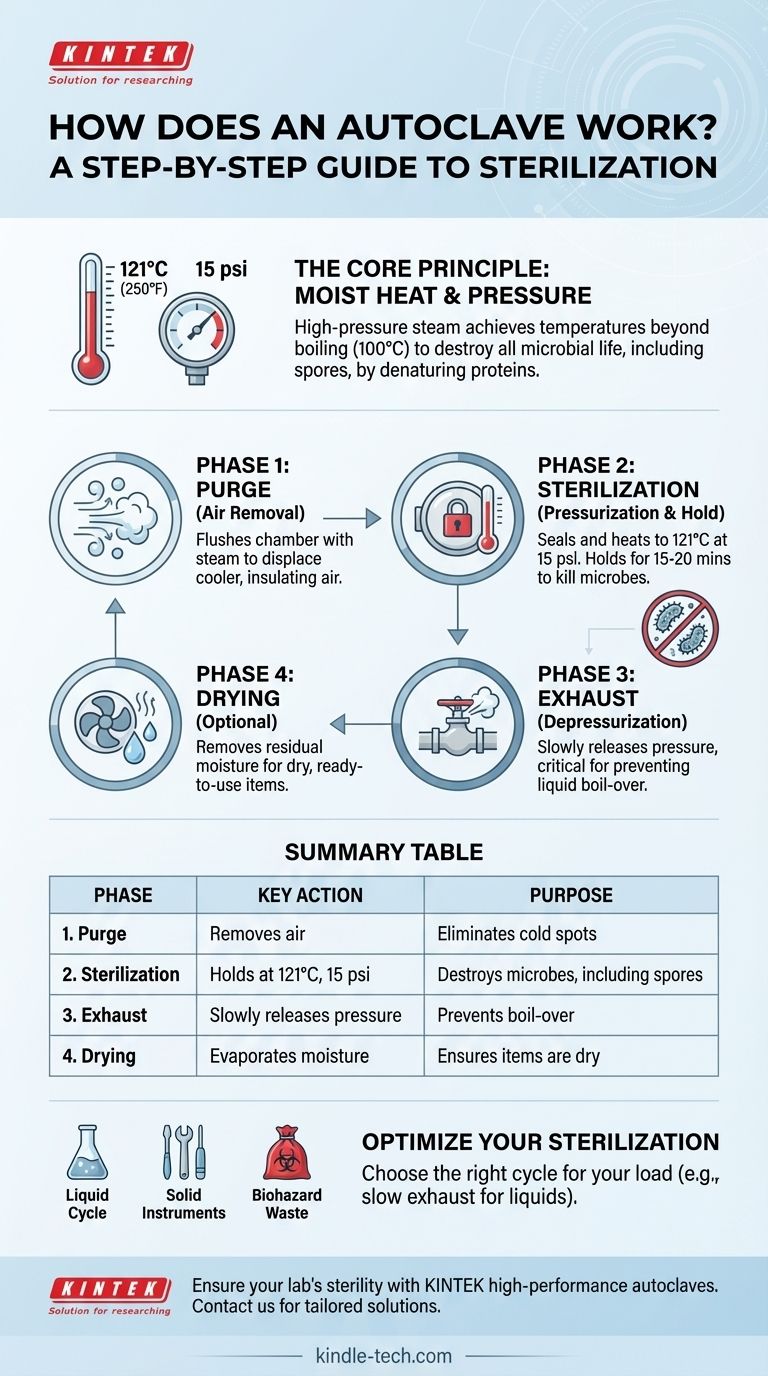

The Core Principle: Why Pressure is Essential

Moving Beyond Simple Boiling

Standard boiling is a method of disinfection, but it is not a method of sterilization. Many dangerous microbes, particularly bacterial spores, can survive being boiled in water at standard atmospheric pressure.

To achieve true sterilization, a higher temperature is required. This is where the laws of physics come into play.

The Physics of Pressurized Steam

The boiling point of water is directly related to the pressure surrounding it. At sea level, water boils at 100°C (212°F).

By sealing a chamber and increasing the internal pressure, an autoclave forces water to remain liquid at higher temperatures. When it finally turns to steam, that steam is significantly hotter than 100°C.

Typically, an autoclave operates at a pressure of about 15 pounds per square inch (psi) above atmospheric pressure. This allows it to generate saturated steam at 121°C (250°F), the standard temperature required for effective sterilization.

How Moist Heat Kills Microbes

The high-temperature steam is lethal to microorganisms. It works by denaturing and coagulating the essential proteins and enzymes within the cells.

This process is irreversible. The cellular structures are fundamentally destroyed, preventing the microbes from metabolizing or reproducing.

The Autoclave Cycle: A Step-by-Step Breakdown

A complete autoclave cycle is a precisely controlled, automated process designed for safety and effectiveness. It can be broken down into four distinct phases.

Phase 1: The Purge Cycle (Air Removal)

Before sterilization can begin, all air must be removed from the chamber. Air is a poor conductor of heat and can create insulating "cold spots" that prevent steam from reaching and sterilizing all surfaces.

The autoclave purges this air by flushing the chamber with steam, effectively displacing the cooler, less-dense air.

Phase 2: The Sterilization Cycle (Pressurization & Hold)

Once the air is removed, the steam inlet and exhaust valves close, sealing the chamber. Steam is continuously pumped in, causing both the pressure and temperature to rise until they reach the target setpoint (e.g., 121°C and 15 psi).

The autoclave then holds these conditions for a specific duration, known as the hold time, which is typically 15-20 minutes. This is the period when the actual sterilization occurs.

Phase 3: The Exhaust Cycle (Depressurization)

After the hold time is complete, an exhaust valve opens to slowly and safely release the pressure from the chamber.

This phase is critical, especially when sterilizing liquids. Releasing pressure too quickly would cause the superheated liquids to boil violently, a phenomenon known as "boil-over."

Phase 4: The Drying Cycle (Optional)

For loads containing instruments, glassware, or other hard goods, a drying cycle is often initiated. The heat from the chamber walls turns the remaining moisture into steam, which is then removed by a vacuum system.

This ensures the items are completely dry and ready for use or storage, preventing potential recontamination from wet surfaces.

Understanding the Key Trade-offs

Load Size and Density Matter

A small, loosely packed load will sterilize much faster than a large, dense load. The hold time must be long enough to ensure the steam penetrates to the very center of the densest item in the chamber.

Adjusting the cycle time based on the load is critical for guaranteeing sterilization.

The Problem of Trapped Air

Improper loading is a common cause of sterilization failure. If items are packed too tightly or placed in solid-bottomed containers, air can become trapped.

These pockets of trapped air prevent direct steam contact, leaving those areas unsterilized. Always ensure steam has a clear path to all surfaces.

Making the Right Choice for Your Goal

To ensure success, your autoclave settings must match the material you are sterilizing.

- If your primary focus is sterilizing liquids (like media or buffers): Ensure you use a "liquid cycle" with a slow, controlled exhaust to prevent dangerous boil-over.

- If your primary focus is sterilizing solid instruments (glassware or metal tools): Use a "gravity" or "vacuum" cycle that includes a post-sterilization drying phase to ensure items are ready for immediate use.

- If your primary focus is sterilizing biohazardous waste: Use a cycle with an extended hold time to guarantee complete heat penetration through the dense, insulated waste bags.

Ultimately, the autoclave is a powerful tool that leverages basic principles of physics to provide the highest standard of safety and sterility in scientific and medical environments.

Summary Table:

| Phase | Key Action | Purpose |

|---|---|---|

| 1. Purge | Removes air from the chamber | Eliminates cold spots for uniform steam penetration |

| 2. Sterilization | Holds at 121°C (250°F) and 15 psi | Destroys microbes, including spores, via moist heat |

| 3. Exhaust | Slowly releases pressure | Prevents boil-over, especially for liquids |

| 4. Drying (Optional) | Evaporates residual moisture | Ensures items are dry and ready for use or storage |

Ensure your lab's sterility and safety with the right equipment. KINTEK specializes in high-performance autoclaves and lab consumables designed for reliable, efficient sterilization cycles. Whether you process liquids, instruments, or biohazardous waste, our solutions are tailored to meet rigorous laboratory standards. Contact our experts today to find the perfect autoclave for your specific needs and enhance your lab's efficiency and compliance.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- Where should an autoclave be located in a lab? Balance Safety and Efficiency for Optimal Workflow

- What is autoclave in laboratory? Achieve Total Sterility for Your Lab

- What is an autoclave laboratory equipment? The Ultimate Guide to Steam Sterilization

- What is the temperature of autoclave in microbiology lab? Achieve Sterile Conditions with 121°C

- Is a UV sterilizer as good as an autoclave? The Critical Difference Between Sterilization and Disinfection