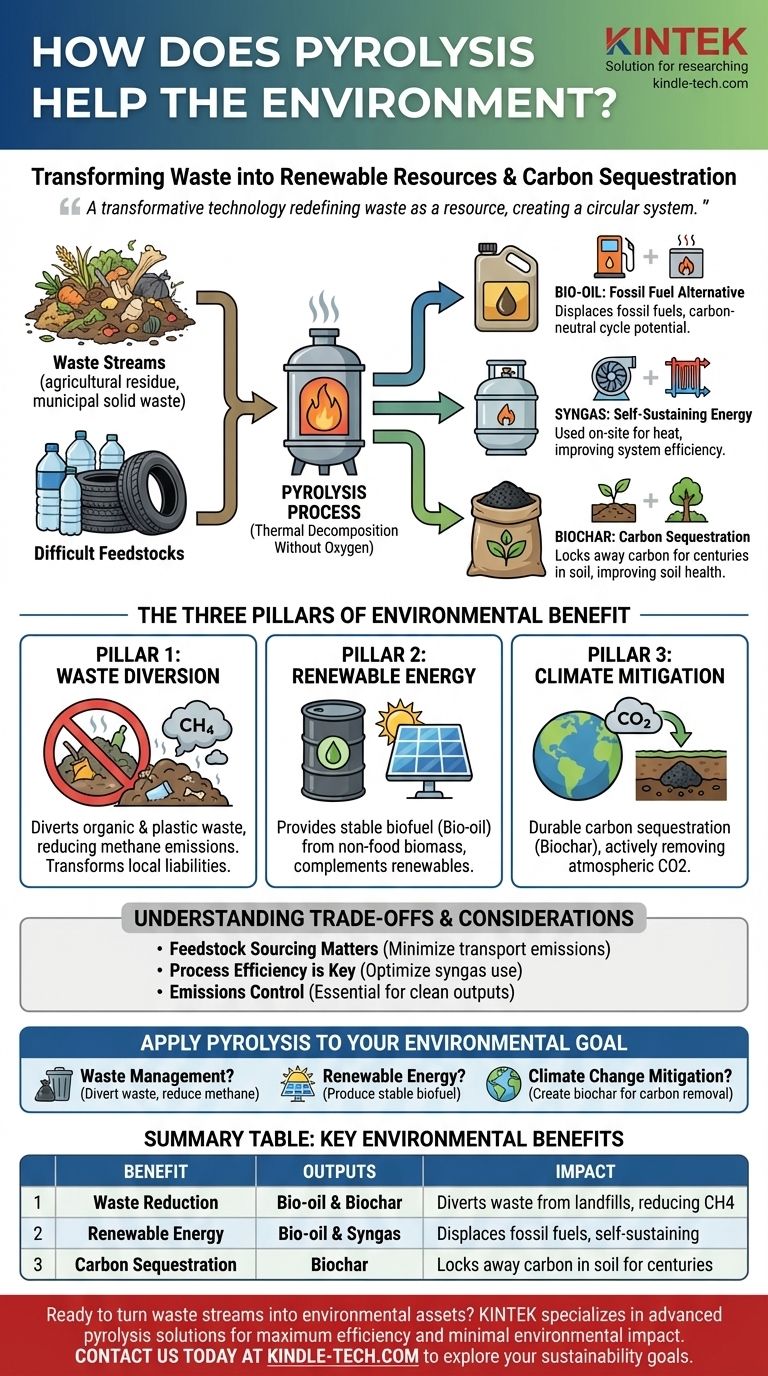

Fundamentally, pyrolysis helps the environment by thermally decomposing waste materials in the absence of oxygen. This process avoids the direct combustion that creates high emissions and instead transforms problematic waste—like agricultural residue, plastics, and municipal solid waste—into valuable, environmentally beneficial products. The three core benefits are the reduction of landfill waste, the creation of renewable energy, and the long-term sequestration of carbon.

Pyrolysis is more than just a waste disposal method; it is a transformative technology. It redefines waste as a resource, creating a circular system where organic and plastic materials are converted into renewable fuel and a stable form of carbon that can be returned to the earth.

From Waste Problem to Resource Solution

The primary environmental value of pyrolysis begins with its ability to intercept waste streams that would otherwise cause significant harm. It provides a productive end-of-life pathway for materials that are difficult to manage.

Diverting Waste from Landfills

Landfills are a major source of methane, a greenhouse gas far more potent than carbon dioxide. By diverting organic and plastic waste to a pyrolysis facility, these methane emissions are avoided.

Instead of slowly decomposing and releasing harmful gases, the carbon in the waste is captured and repurposed, drastically reducing the environmental footprint of waste management.

Processing Diverse and Difficult Feedstocks

Pyrolysis is remarkably versatile. It can process a wide range of materials, including agricultural residues (straw, husks), wood waste, and even end-of-life plastics and tires.

This flexibility allows communities to address their specific waste challenges, turning local liabilities into local assets without the need for long-distance transport.

Creating High-Density, Transportable Fuel

Raw biomass is often bulky, wet, and inefficient to transport. Pyrolysis converts this low-density solid into a high-density liquid called bio-oil.

This liquid is far cheaper and more energy-efficient to store and transport than the original feedstock. It can then be used in remote locations or refined further, reducing the overall carbon footprint associated with biomass logistics.

The Three Pillars of Environmental Benefit

The outputs of the pyrolysis process deliver distinct and complementary environmental advantages. By understanding these three products—bio-oil, syngas, and biochar—we can see the full scope of its impact.

Pillar 1: Bio-oil as a Fossil Fuel Alternative

Bio-oil is a liquid fuel that can be used to generate heat and power, directly displacing fossil fuels like heating oil or diesel in certain applications.

Because the carbon in bio-oil was recently captured from the atmosphere by plants (in the case of biomass), its use is considered part of a much shorter, often carbon-neutral cycle compared to burning fossil fuels.

Pillar 2: Syngas for Self-Sustaining Energy

Pyrolysis also produces a non-condensable gas called syngas. This gas has significant energy value and is typically used on-site to provide the heat needed to run the pyrolysis process itself.

This creates a self-sustaining system that requires minimal external energy input, dramatically improving the net energy balance and overall efficiency of the operation.

Pillar 3: Biochar for Carbon Sequestration

Perhaps the most powerful environmental benefit is the creation of biochar, a solid, charcoal-like material rich in stable carbon.

Unlike biomass that decomposes and releases its carbon back into the atmosphere, biochar is highly resistant to degradation. When added to soil, it effectively locks away that carbon for hundreds or even thousands of years. This process is a direct form of carbon sequestration, actively removing CO2 from the atmospheric cycle.

Understanding the Trade-offs and Considerations

While powerful, pyrolysis is not a silver bullet. Its environmental benefits depend entirely on responsible design and operation.

Feedstock Sourcing Matters

The sustainability of pyrolysis is tied to its feedstock. Using locally sourced waste is ideal. Transporting biomass over vast distances can generate significant emissions, potentially offsetting the climate benefits of the process.

Process Emissions and By-products

A poorly designed or operated pyrolysis unit can release harmful pollutants. The specific chemical composition of the feedstock—especially in mixed plastics or contaminated waste—determines the characteristics of the outputs. Proper controls are essential to ensure the bio-oil and biochar are clean and the process emissions are scrubbed.

The Importance of System Efficiency

The claim that pyrolysis is "highly efficient" is a potential, not a guarantee. The system must be engineered to effectively capture and use the energy in the syngas. If this energy is wasted, the process can become a net energy consumer, undermining its environmental purpose.

Applying Pyrolysis to Your Environmental Goal

To make an informed decision, align the specific benefits of pyrolysis with your primary objective.

- If your primary focus is waste management: Pyrolysis is a powerful tool for diverting organic and plastic waste from landfills, directly reducing methane emissions and creating value from discarded materials.

- If your primary focus is renewable energy: The technology provides a stable, storable liquid biofuel (bio-oil) from non-food biomass, complementing intermittent renewables like solar and wind.

- If your primary focus is climate change mitigation: The production of biochar offers a unique and durable method for active carbon sequestration, directly removing atmospheric CO2 and improving soil health.

Ultimately, pyrolysis provides a sophisticated technical path for converting environmental liabilities into valuable assets for a more circular economy.

Summary Table:

| Environmental Benefit | Key Output | Primary Impact |

|---|---|---|

| Waste Reduction | Bio-oil & Biochar | Diverts waste from landfills, reducing methane emissions |

| Renewable Energy | Bio-oil & Syngas | Displaces fossil fuels with self-sustaining energy |

| Carbon Sequestration | Biochar | Locks away carbon in soil for centuries |

Ready to turn your waste streams into environmental assets? KINTEK specializes in advanced pyrolysis equipment and consumables for laboratories and industrial facilities. Whether your goal is waste management, renewable energy production, or carbon sequestration, our solutions are engineered for maximum efficiency and minimal environmental impact. Contact us today to explore how our technology can help you achieve your sustainability goals and contribute to a circular economy.

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What are the main types of biomass conversion processes? Unlock the Best Pathway for Your Energy Needs

- How do high-temperature reaction furnaces control in-situ MMCs? Master Material Precision and Structural Integrity

- What temperature is needed for pyrolysis waste? A Guide to Optimizing Your Waste-to-Value Process

- What is the range of pyrolysis? Master Temperature Control for Optimal Bio-Product Yields

- How is a high-temperature calcination furnace utilized in BZY20 Sol-gel? Achieve Pure Cubic Perovskite Phases