An autoclave sterilizes materials by using high-pressure steam to generate intense heat far above the boiling point of water. This combination of moist heat and pressure is lethal to all forms of microbial life, including the most resilient bacterial spores, by irreversibly damaging their essential proteins and enzymes.

The true power of an autoclave lies not in the heat alone, but in the moist heat delivered under pressure. This principle allows steam to reach temperatures like 121°C (250°F), ensuring rapid and complete penetration into materials to destroy microorganisms from the inside out.

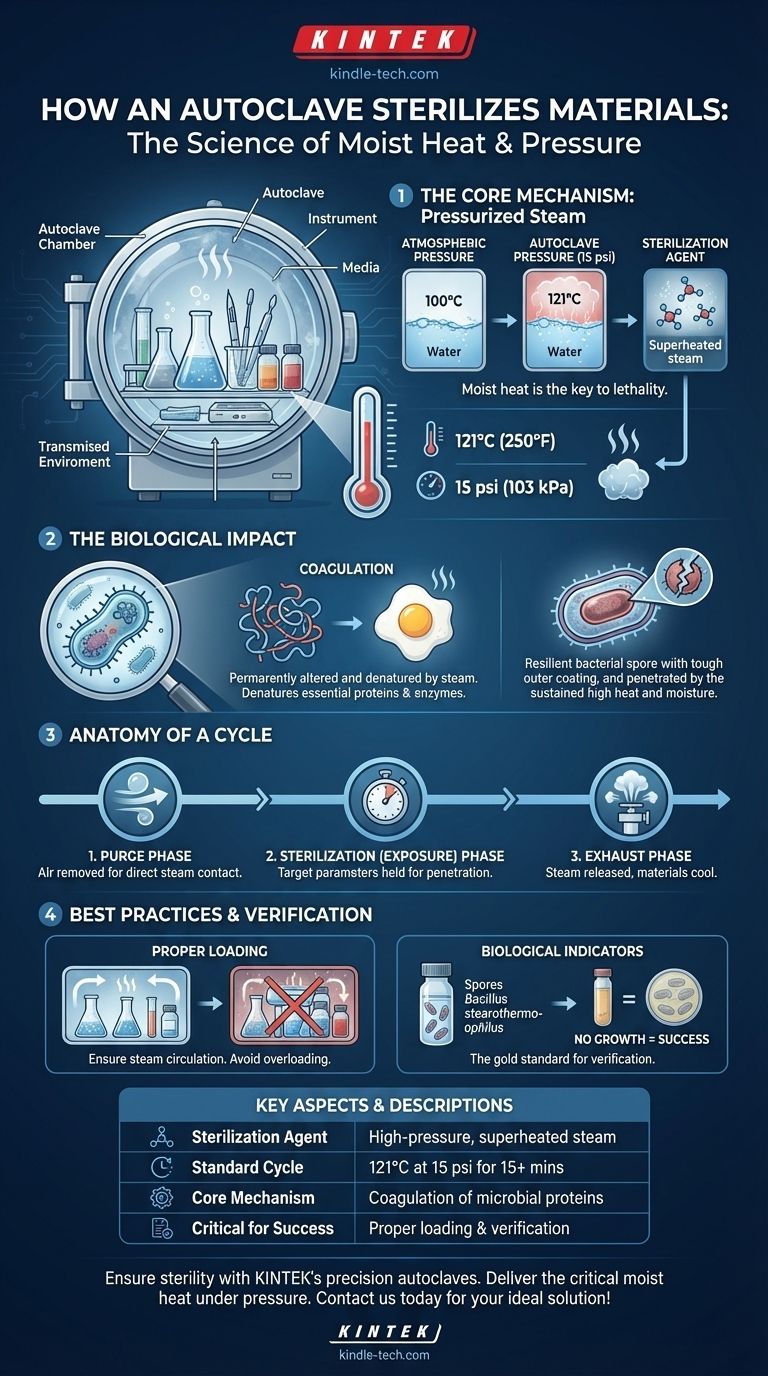

The Core Mechanism: How Pressurized Steam Works

An autoclave's effectiveness comes from a precise combination of physical and biological principles. It manipulates the properties of water to create an environment that is incompatible with life.

The Critical Role of Pressure

Under normal atmospheric conditions, water boils at 100°C (212°F). By increasing the pressure inside the sealed autoclave chamber to approximately 15 pounds per square inch (psi), the boiling point of water is raised to 121°C (250°F).

This superheated steam is the primary sterilization agent.

The Biological Impact of Moist Heat

The moisture in the steam is the key to its lethality. It works by a process called coagulation, rapidly and irreversibly denaturing the essential proteins and enzymes that all microorganisms rely on to live and reproduce.

Think of it like cooking an egg: the moist heat fundamentally and permanently changes the structure of the proteins. This process is far more efficient than dry heat sterilization.

Eliminating Heat-Resistant Spores

Many bacteria can form highly resistant spores as a survival mechanism. These spores can withstand boiling and many chemical disinfectants.

However, the sustained high temperature and moisture of an autoclave cycle are sufficient to penetrate these tough outer coatings and destroy the spore from within, ensuring true sterility.

Anatomy of a Standard Sterilization Cycle

A typical autoclave cycle is a carefully controlled, multi-stage process designed for maximum effectiveness and safety.

The Purge Phase

Before sterilization begins, all air must be removed from the chamber. Air pockets can act as an insulating barrier, preventing steam from making direct contact with the surfaces of the items being sterilized.

The Sterilization (Exposure) Phase

Once the chamber is filled with pure steam, the temperature and pressure are raised to the target level. A standard cycle holds items at 121°C and 15 psi for at least 15 minutes. This duration ensures the steam has enough time to penetrate all materials.

The Exhaust Phase

After the exposure time is complete, the steam is slowly released from the chamber, and the pressure returns to ambient levels. Materials are then allowed to cool before being removed.

Common Pitfalls and Best Practices

Simply running a cycle is not a guarantee of sterility. Proper use and verification are critical for ensuring the process was successful.

The Danger of Improper Loading

Overloading the autoclave or packing items too tightly prevents steam from circulating freely. This is one of the most common causes of a failed sterilization cycle.

Materials should be arranged to allow for maximum steam penetration, often using specialized stainless steel boxes or trays with ventilation.

The Need for Verification

You cannot assume a cycle was successful just because the machine ran. The gold standard for verification is the use of biological indicators.

These indicators contain spores of a highly heat-resistant, non-pathogenic bacterium, typically Bacillus stearothermophilus. After a cycle, these indicators are incubated. If no growth occurs, it confirms that the autoclave successfully created conditions lethal to even the toughest organisms.

Making the Right Choice for Your Goal

Understanding the autoclave's mechanism allows you to use it as a precise and reliable tool.

- If your primary focus is ensuring absolute sterility: Always validate your cycles using biological indicators, especially for critical applications like medical instruments or cell culture media.

- If your primary focus is process efficiency: Pay close attention to proper loading techniques to prevent failed cycles, which waste time, energy, and resources.

- If your primary focus is understanding the science: Remember that coagulation is the key. It's the moist heat's ability to denature microbial proteins that makes autoclaving the definitive standard for sterilization.

Ultimately, mastering the principles of autoclaving transforms it from a simple machine into a reliable guardian of scientific and medical integrity.

Summary Table:

| Key Aspect | Description |

|---|---|

| Sterilization Agent | High-pressure, superheated steam |

| Standard Cycle | 121°C (250°F) at 15 psi for 15+ minutes |

| Core Mechanism | Coagulation (denaturation) of microbial proteins |

| Critical for Success | Proper loading and verification with biological indicators |

Ensure your laboratory's sterility and integrity with KINTEK's precision autoclaves.

Our autoclaves are engineered for reliable, efficient sterilization cycles, providing the critical moist heat under pressure needed to destroy even the most resistant bacterial spores. Whether you're working with medical instruments, cell culture media, or other lab consumables, KINTEK's solutions deliver the performance and verification tools you need for absolute confidence.

Contact us today to find the perfect autoclave solution for your laboratory's specific needs and enhance your sterility protocols!

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

People Also Ask

- What autoclave is used for sterilization? The Definitive Guide to Steam Sterilization

- Is a sterilizer an autoclave? Understand the Key Differences for Your Lab

- Why is it important to autoclave the prepared reagents before using? Ensure Sterility and Reliable Results

- What is the life expectancy of an autoclave machine? Maximize Your Investment with Proper Care

- What are the 4 principles of autoclave? Master Steam Sterilization for Your Lab