In short, PVD-coated stainless steel is exceptionally durable. The Physical Vapor Deposition (PVD) process creates a surface layer that is significantly harder and more resistant to wear and corrosion than the stainless steel itself. This makes it one of the most durable colored finishes available for metal products.

The core takeaway is that PVD is not a paint or a simple plating; it's a high-tech process that molecularly bonds a thin ceramic film to the steel. This results in a finish that dramatically increases hardness and resistance to scratches and tarnishing, though it is not completely indestructible against aggressive damage.

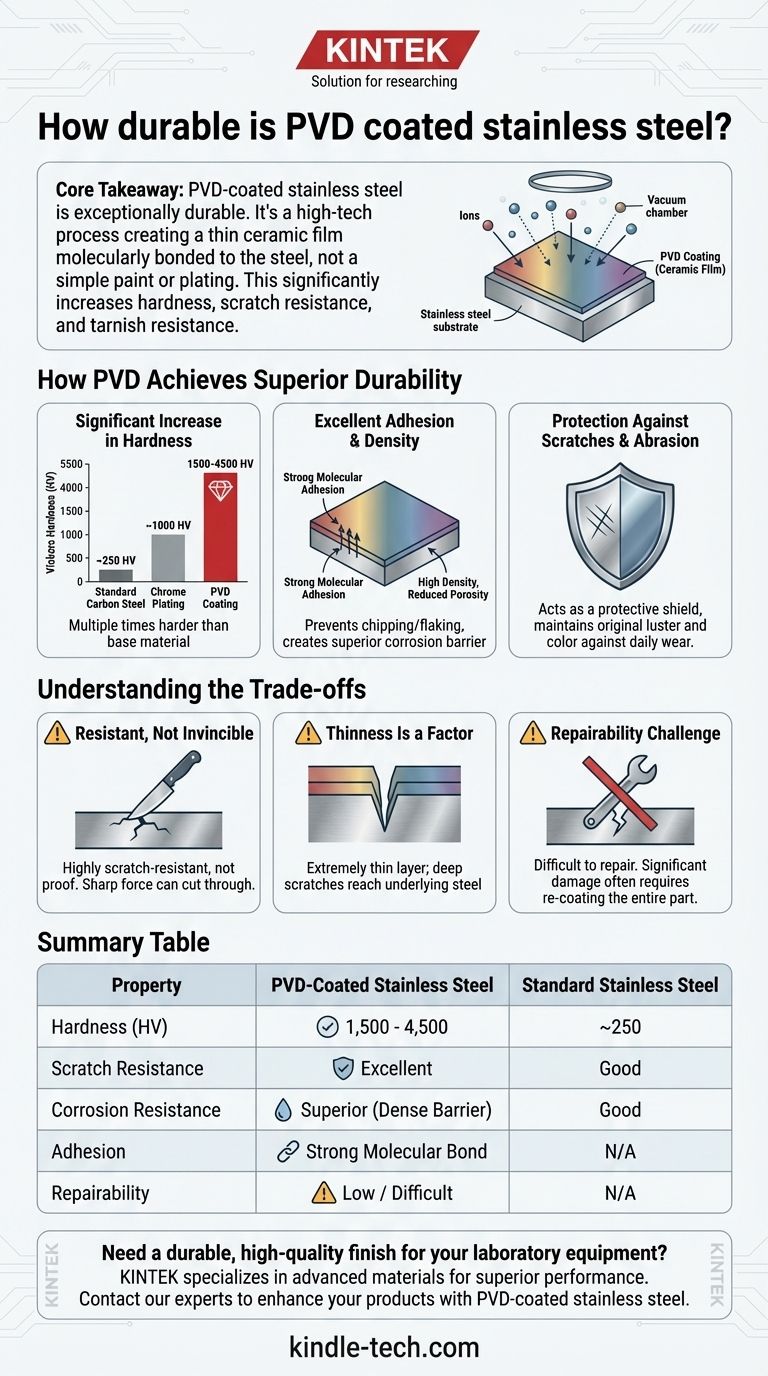

How PVD Achieves Superior Durability

The remarkable durability of a PVD coating stems directly from the advanced physics of its application process. It fundamentally changes the surface properties of the stainless steel.

A Significant Increase in Hardness

The most direct measure of durability is hardness. A PVD coating has a Vickers hardness (HV) value between 1500 and 4500.

To put this in perspective, standard carbon steels are around 250 HV. Even traditionally durable finishes like chrome plating or nitrided steels top out around 1000 HV. The PVD coating is, therefore, multiple times harder than the base material it protects.

Excellent Adhesion and Density

The PVD process involves ion bombardment in a vacuum chamber, which creates an incredibly dense and well-bonded coating. This strong molecular adhesion prevents the chipping or flaking commonly seen in lesser coating methods.

The high density of the coating also reduces porosity, creating a superior barrier against corrosion and environmental factors that could otherwise tarnish or discolor the steel.

Protection Against Scratches and Abrasion

This combination of extreme hardness and strong adhesion results in a surface with excellent resistance to everyday scratches and abrasions. The PVD layer acts as a protective shield for the stainless steel beneath it, maintaining the product's original luster and color for much longer than an uncoated or painted product.

Understanding the Trade-offs

While PVD is a top-tier finish, no material is invincible. Understanding its limitations is key to making an informed decision.

It Is Resistant, Not Invincible

PVD coatings are highly scratch-resistant, but not scratch-proof. A sufficiently sharp or aggressive force can cut through the coating. While it will withstand daily bumps and scuffs with ease, a deep gouge from a sharp tool or a hard impact against a rough surface can still cause damage.

The Thinness Is a Factor

PVD coatings are extremely thin, which is a benefit because they perfectly replicate the texture of the underlying material without softening details. However, this thinness means a deep scratch has less material to penetrate before it reaches the stainless steel below.

Repairability Can Be a Challenge

Unlike a painted surface that can be touched up, a damaged PVD coating is very difficult to repair. In most cases, a significant scratch or gouge may not be repairable, and the entire part would need to be re-coated, which is often not practical.

Making the Right Choice for Your Product

PVD-coated stainless steel offers an outstanding combination of aesthetic finish and robust performance. Your specific application will determine if it's the right choice.

- If your primary focus is daily wear and longevity: PVD is an excellent choice, providing superior protection against the minor scuffs, discoloration, and tarnishing that affect watches, faucets, and jewelry.

- If your product will face heavy, aggressive impacts: Be aware that while PVD is tough, a deep gouge can compromise the coating, and repairs are generally not an option.

- If your primary focus is a lasting aesthetic: PVD provides a durable, vibrant color finish that preserves the underlying texture of the stainless steel far better than other coating methods.

By understanding these properties, you can confidently choose PVD-coated stainless steel for its remarkable blend of durability and design.

Summary Table:

| Property | PVD-Coated Stainless Steel | Standard Stainless Steel |

|---|---|---|

| Hardness (HV) | 1,500 - 4,500 | ~250 |

| Scratch Resistance | Excellent | Good |

| Corrosion Resistance | Superior (Dense Barrier) | Good |

| Adhesion | Strong Molecular Bond | N/A |

| Repairability | Low / Difficult | N/A |

Need a durable, high-quality finish for your laboratory equipment or components? KINTEK specializes in providing advanced lab equipment and consumables. Our expertise ensures you get the right materials for superior performance and longevity. Contact our experts today to discuss how PVD-coated stainless steel can enhance your products!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells