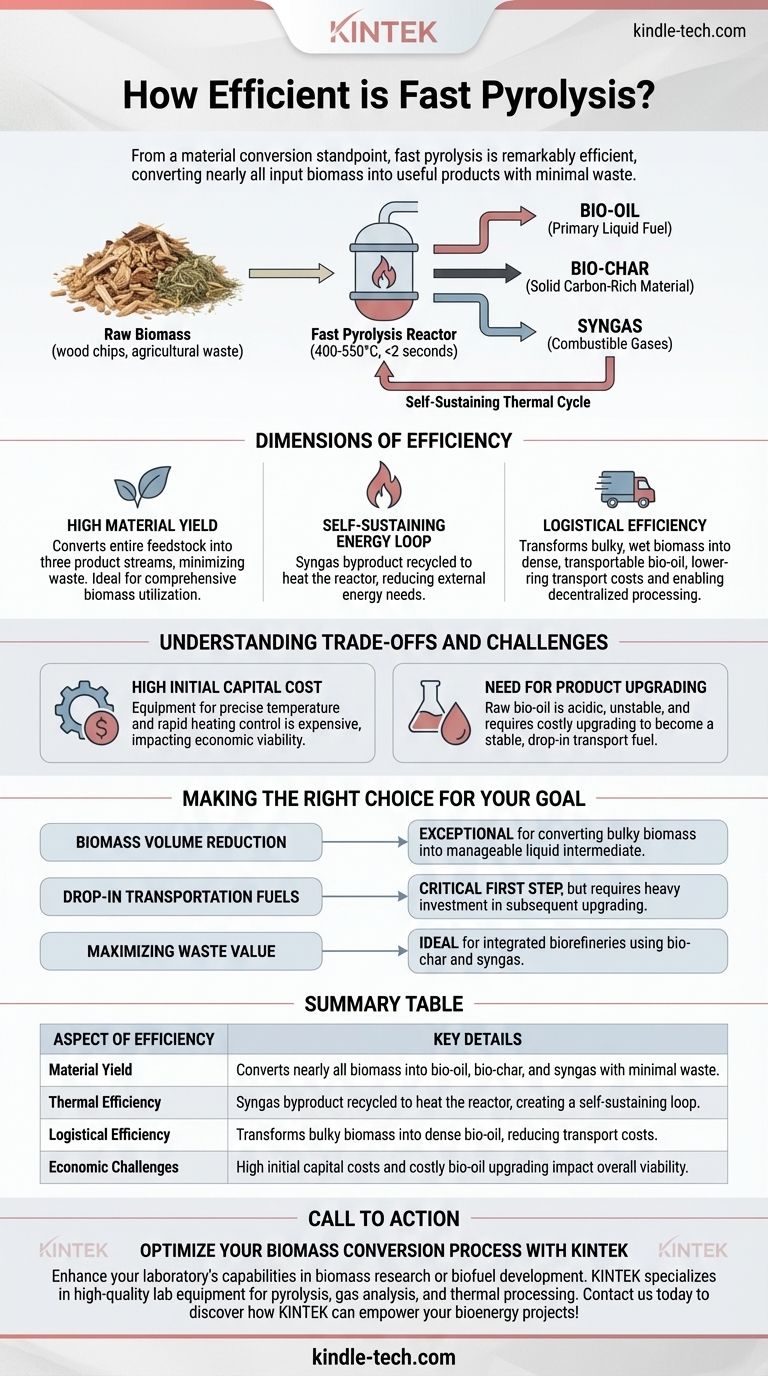

From a material conversion standpoint, fast pyrolysis is remarkably efficient. The process is designed to convert nearly all of the input biomass into useful products with minimal waste. The primary output is a liquid bio-oil, supplemented by solid bio-char and combustible syngas. Crucially, the syngas can be recycled to heat the reactor, creating a highly self-sustaining thermal cycle.

The true efficiency of fast pyrolysis isn't just about high product yield; it's about its strategic ability to transform solid, bulky biomass into a dense, transportable liquid fuel. However, this process efficiency must be weighed against the significant economic costs and post-processing steps required to make the end products commercially viable.

The Core Principle of Fast Pyrolysis

Rapid Thermal Conversion

Fast pyrolysis works by heating biomass to high temperatures (400-550°C) in an environment with no oxygen.

This process is defined by its speed, requiring very high heating rates and a short residence time for the biomass, typically less than two seconds.

The Three Key Products

This rapid decomposition avoids extensive chemical breakdown, resulting in three primary outputs.

The main product is bio-oil, a liquid biofuel. The process also yields a solid carbon-rich material called bio-char and a mixture of flammable gases known as syngas (methane, hydrogen, carbon monoxide).

Dimensions of Efficiency in Fast Pyrolysis

High Material Yield

A key advantage of fast pyrolysis is its ability to process all components of the biomass.

Unlike some biological conversion methods that only target specific sugars or celluloses, pyrolysis converts the entire feedstock into one of the three product streams. This comprehensive conversion minimizes waste.

The Self-Sustaining Energy Loop

The process exhibits high thermal efficiency due to the nature of its co-products.

The syngas produced has significant energy value and can be immediately burned to provide the heat needed to run the pyrolysis reactor. This creates a self-powering system, reducing the need for external energy inputs once the process is running.

Logistical Efficiency

Fast pyrolysis excels at solving a core logistical challenge: biomass is often bulky, wet, and difficult to transport.

The process converts this low-density solid into a high-density liquid bio-oil, which is far easier and cheaper to store and transport to a central upgrading facility. This allows for smaller, mobile reactors to be placed near the biomass source.

Understanding the Trade-offs and Challenges

High Initial Capital Cost

While the reactor principles are relatively simple, the equipment required to achieve the precise temperature control and rapid heating rates of fast pyrolysis can be expensive.

This initial investment is a significant barrier to widespread adoption and impacts the overall economic efficiency of a project.

The Need for Product Upgrading

The term "bio-oil" can be misleading. It is not a direct substitute for crude oil and cannot be used in conventional engines without significant processing.

Bio-oil is acidic, unstable, and contains high levels of water and oxygen. It requires costly and energy-intensive upgrading (such as hydrotreating) to be converted into a stable, transport-grade fuel. This post-processing reality must be factored into any efficiency calculation.

Making the Right Choice for Your Goal

Evaluating fast pyrolysis requires aligning its specific strengths with your primary objective.

- If your primary focus is biomass volume reduction and transport: Fast pyrolysis is exceptionally effective at converting scattered, low-density biomass into an easily managed liquid intermediate.

- If your primary focus is creating drop-in transportation fuels: View fast pyrolysis as a critical first step, but be prepared to invest heavily in the subsequent separation and upgrading infrastructure.

- If your primary focus is maximizing value from waste streams: The process is ideal for integrated biorefineries where bio-char can be used for soil amendment and the syngas can power the facility.

Ultimately, fast pyrolysis is best understood not as a single solution, but as a powerful enabling step in a larger bioenergy value chain.

Summary Table:

| Aspect of Efficiency | Key Details |

|---|---|

| Material Yield | Converts nearly all biomass into bio-oil (primary), bio-char, and syngas with minimal waste. |

| Thermal Efficiency | Syngas byproduct can be recycled to heat the reactor, creating a self-sustaining energy loop. |

| Logistical Efficiency | Transforms bulky biomass into a dense, transportable liquid (bio-oil), reducing transport costs. |

| Economic Challenges | High initial capital costs and the need for costly bio-oil upgrading impact overall viability. |

Optimize Your Biomass Conversion Process with KINTEK

Are you looking to enhance your laboratory's capabilities in biomass research or biofuel development? KINTEK specializes in high-quality lab equipment and consumables tailored for pyrolysis, gas analysis, and thermal processing applications. Our reliable reactors, temperature control systems, and analytical tools help you achieve precise, efficient results—whether you're scaling up bio-oil production, analyzing bio-char properties, or optimizing syngas utilization.

Let us support your innovation with equipment that ensures accuracy, durability, and seamless integration into your workflow. Contact us today to discuss your specific needs and discover how KINTEK can empower your bioenergy projects!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- What are the products of pyrolysis of wood? A Guide to Biochar, Bio-oil, and Syngas Yields

- What are the industrial applications of pyrolysis? Transform Waste into Energy and Valuable Products

- What is the principle of rotary kiln? Mastering Continuous Thermal Processing

- What is the difference between calcining and roasting? A Guide to High-Temperature Processing

- What are the zones in rotary kiln in cement production? Master the Core Process for High-Quality Clinker