Defining the "efficiency" of pyrolysis is complex because it is not a single, universal number. The efficiency of the process depends entirely on three factors: the type of organic waste being processed (the feedstock), the specific pyrolysis technology used, and the desired end product you are trying to create, such as biofuels or recovered chemicals.

The true measure of pyrolysis efficiency is not a single number. It is a strategic balance between energy conversion, valuable material recovery, and waste reduction, with the optimal method depending entirely on the specific goal and input material.

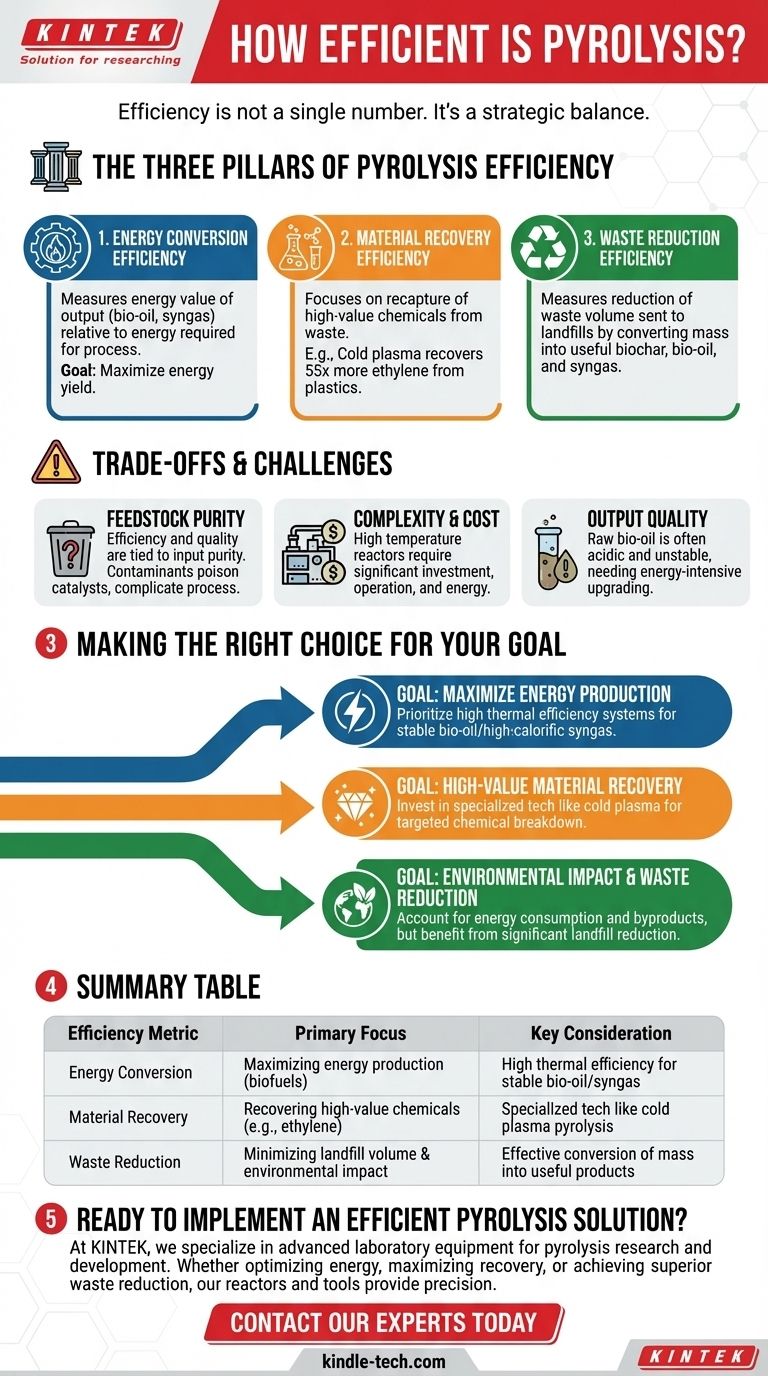

The Three Pillars of Pyrolysis Efficiency

To understand the effectiveness of pyrolysis, we must evaluate it across three distinct metrics. A process that excels in one area may be average in another.

1. Energy Conversion Efficiency

This is the most common interpretation of efficiency. It measures the energy value of the output products (like bio-oil and syngas) relative to the energy required to run the pyrolysis process itself.

A system with high energy efficiency produces biofuels that contain significantly more energy than was consumed to heat the feedstock and operate the equipment.

2. Material Recovery Efficiency

This metric focuses on the yield of specific, high-value products recovered from the waste stream. It is less about energy and more about recapturing valuable molecules.

For example, specialized techniques can dramatically increase the recovery of certain chemicals. Cold plasma pyrolysis is a highly efficient method that can recover 55 times more ethylene from plastic waste compared to conventional thermal pyrolysis.

This highlights how a process can be extremely efficient for a specific, targeted goal, such as creating chemical building blocks instead of fuel.

3. Waste Reduction Efficiency

This is an environmental metric that measures how effectively pyrolysis reduces the volume of waste sent to landfills.

From this perspective, nearly all pyrolysis systems are highly efficient. They convert the majority of an organic material's mass into useful solids (biochar), liquids (bio-oil), and gases (syngas), minimizing the final disposal footprint.

Understanding the Trade-offs and Challenges

While promising, pyrolysis is not a perfect solution. An objective evaluation requires acknowledging its operational complexities.

Feedstock Purity is Critical

The efficiency and quality of the output are directly tied to the purity of the input material. Contaminated waste streams can poison catalysts, reduce the value of the bio-oil, and complicate the entire process.

Process Complexity and Cost

Pyrolysis reactors are sophisticated industrial systems that require significant capital investment and skilled operators. The energy required to reach and maintain high temperatures is a major operational cost that impacts overall efficiency.

Output Quality and Upgrading

The raw output, particularly bio-oil, is often acidic, unstable, and requires further processing (upgrading) before it can be used as a direct replacement for fossil fuels. This additional step consumes more energy and adds cost, affecting the net efficiency of the entire fuel production cycle.

Making the Right Choice for Your Goal

The "best" pyrolysis approach is defined by your primary objective. You must align the technology with your specific end goal.

- If your primary focus is maximizing energy production: Prioritize systems with high thermal efficiency that are designed to produce a stable bio-oil or a high-calorific syngas from biomass.

- If your primary focus is high-value material recovery: Invest in specialized technologies like cold plasma pyrolysis, designed to break down specific feedstocks like plastics into valuable chemical components.

- If your primary focus is environmental impact and waste reduction: Almost any pyrolysis system offers a significant benefit over landfilling, but you must still account for the energy consumption and byproduct management of the process.

Ultimately, efficient pyrolysis is not about finding a single best method, but about precisely aligning the technology with the intended outcome.

Summary Table:

| Efficiency Metric | Primary Focus | Key Consideration |

|---|---|---|

| Energy Conversion | Maximizing energy production (biofuels) | High thermal efficiency for stable bio-oil/syngas |

| Material Recovery | Recovering high-value chemicals (e.g., ethylene) | Specialized tech like cold plasma pyrolysis |

| Waste Reduction | Minimizing landfill volume & environmental impact | Effective conversion of mass into useful products |

Ready to implement an efficient pyrolysis solution tailored to your specific goals? At KINTEK, we specialize in advanced laboratory equipment for pyrolysis research and development. Whether your focus is optimizing energy conversion, maximizing material recovery, or achieving superior waste reduction, our reactors and analytical tools provide the precision and reliability you need.

Contact our experts today to discuss how KINTEK can support your pyrolysis projects and help you achieve optimal efficiency.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds