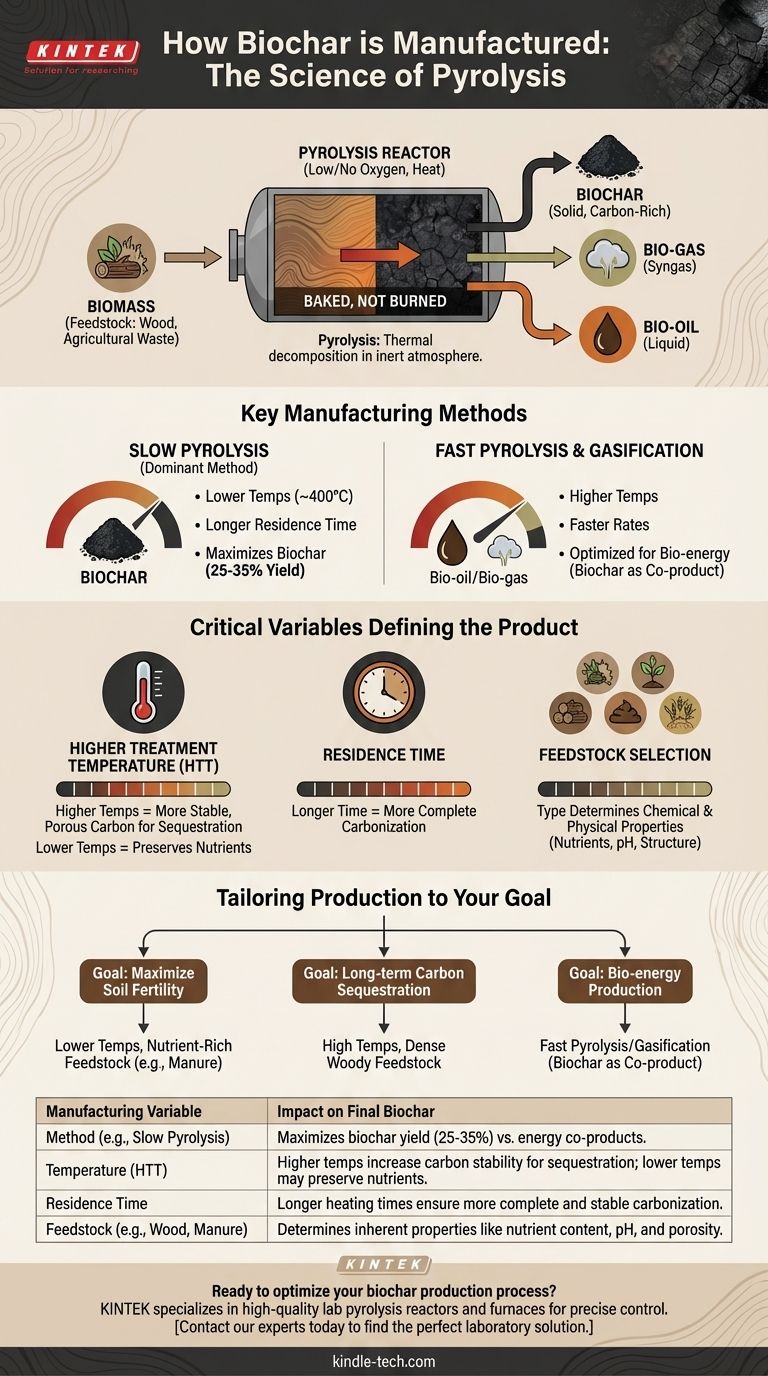

At its core, biochar is manufactured through a process called pyrolysis, which involves heating organic materials like wood or agricultural waste in a low-oxygen or oxygen-free environment. The most common method is slow pyrolysis, where biomass is heated at relatively low temperatures (around 400°C) for several hours, a process designed to maximize the yield of the solid, carbon-rich biochar.

The key takeaway is that biochar manufacturing is not a single, standardized process. The specific method and variables—temperature, heating time, and the type of biomass used—are deliberately controlled to engineer a final product with specific properties for goals like soil improvement or carbon sequestration.

The Core Principle: Pyrolysis

What is Pyrolysis?

Pyrolysis is the thermal decomposition of materials at elevated temperatures in an inert atmosphere. Think of it as "baking" biomass rather than burning it.

Without oxygen, the material doesn't combust into flame and ash. Instead, it breaks down into a solid, liquid, and gas.

The Key Inputs

The process requires two main inputs: a carbon-based organic material, known as feedstock, and a controlled heat source.

Feedstocks can be incredibly varied, including wood chips, crop residues, manure, or other forms of agricultural waste.

The Primary Outputs

Slow pyrolysis separates the biomass into two main products.

The primary output is the solid, stable, carbon-rich material called biochar. A secondary output is a mixture of gases called bio-gas or syngas, which can often be captured and used as an energy source.

Key Manufacturing Methods

Slow Pyrolysis: Maximizing Biochar

Slow pyrolysis is the dominant method for producing biochar. It uses lower temperatures and much longer residence times (the duration the biomass is heated).

This slow-and-low approach is specifically designed to maximize the conversion of biomass into the solid biochar, typically yielding 25-35% of the original material's mass as the final product.

Fast Pyrolysis and Gasification

While less common for dedicated biochar production, other thermal methods exist.

Fast pyrolysis and gasification use much higher temperatures and faster heating rates. These processes are typically optimized to produce bio-oil or syngas for energy, with biochar being a co-product rather than the primary goal.

Critical Variables That Define the Final Product

Highest Treatment Temperature (HTT)

The temperature at which the pyrolysis occurs is arguably the most critical factor.

Higher temperatures generally create a more stable, highly porous biochar with a higher carbon content, making it ideal for long-term carbon sequestration. Lower temperatures may preserve more nutrients from the original feedstock.

Residence Time

The duration of the heating process directly impacts the completeness of the carbonization.

Longer residence times, characteristic of slow pyrolysis, ensure a more thorough conversion of the biomass into a stable char structure.

Feedstock Selection

The type of biomass used fundamentally determines the biochar's inherent chemical and physical properties.

A woody feedstock will produce a very different biochar than one made from manure or corn stover, affecting its nutrient content, pH, and structural integrity.

Understanding the Production Challenges

Variability in Methods

A significant challenge in the biochar industry is the lack of standardization. The wide range of available techniques and process parameters makes it difficult to compare products.

This variability means the performance of one biochar in soil may not be representative of another produced under different conditions.

Feedstock Inconsistency

The broad array of potential feedstocks creates inconsistency. The performance of biochar is directly tied to its source material, making it a crucial variable that must be controlled for reliable results.

Optimizing for a Specific Goal

The ultimate challenge is that there is no single "best" biochar. The production process must be carefully tuned to create a product optimized for a specific application, whether that's improving water retention in sandy soil or immobilizing contaminants.

Tailoring Production to Your Goal

Understanding the manufacturing process allows you to select or create a biochar suited for a specific purpose.

- If your primary focus is maximizing soil fertility: A biochar produced at lower temperatures from a nutrient-rich feedstock like manure is often preferred.

- If your primary focus is long-term carbon sequestration: A biochar produced at a high temperature from a dense, woody feedstock will create the most stable form of carbon.

- If your primary focus is bio-energy production: Fast pyrolysis or gasification would be the chosen method to maximize liquid or gas yields, treating biochar as a valuable co-product.

Mastering the production process is the key to unlocking the full potential of biochar as a tool for agriculture and climate solutions.

Summary Table:

| Manufacturing Variable | Impact on Final Biochar |

|---|---|

| Method (e.g., Slow Pyrolysis) | Maximizes biochar yield (25-35%) vs. energy co-products. |

| Temperature (HTT) | Higher temps increase carbon stability for sequestration; lower temps may preserve nutrients. |

| Residence Time | Longer heating times ensure more complete and stable carbonization. |

| Feedstock (e.g., Wood, Manure) | Determines inherent properties like nutrient content, pH, and porosity. |

Ready to optimize your biochar production process?

The right laboratory equipment is crucial for precise control over pyrolysis variables like temperature and residence time to engineer biochar for your specific application, whether it's soil enhancement or carbon sequestration.

KINTEK specializes in high-quality lab pyrolysis reactors, furnaces, and consumables that provide the reliability and control needed for consistent, high-quality biochar research and development.

Contact our experts today to find the perfect laboratory solution for your biochar manufacturing needs.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- What is the speed of kiln for cement? Mastering the Slow Rotation for Optimal Clinker Quality

- What is the temperature of a carbon regeneration kiln? Mastering the 750-800°C Reactivation Process

- What does calcination remove? A Guide to Thermal Decomposition for Material Processing

- What does calcination do? Purify and Transform Materials with Controlled Heat

- What are the key components of a rotary kiln system? Optimize Your High-Volume Thermal Processing Efficiency

- How is cement prepared by rotary kiln method? A Step-by-Step Guide to Clinker Production

- What is the primary function of a rotary kiln in RSOW processing? Maximize Waste Volume Reduction & Safety

- How does carbon regeneration work? Restore Your Activated Carbon's Performance