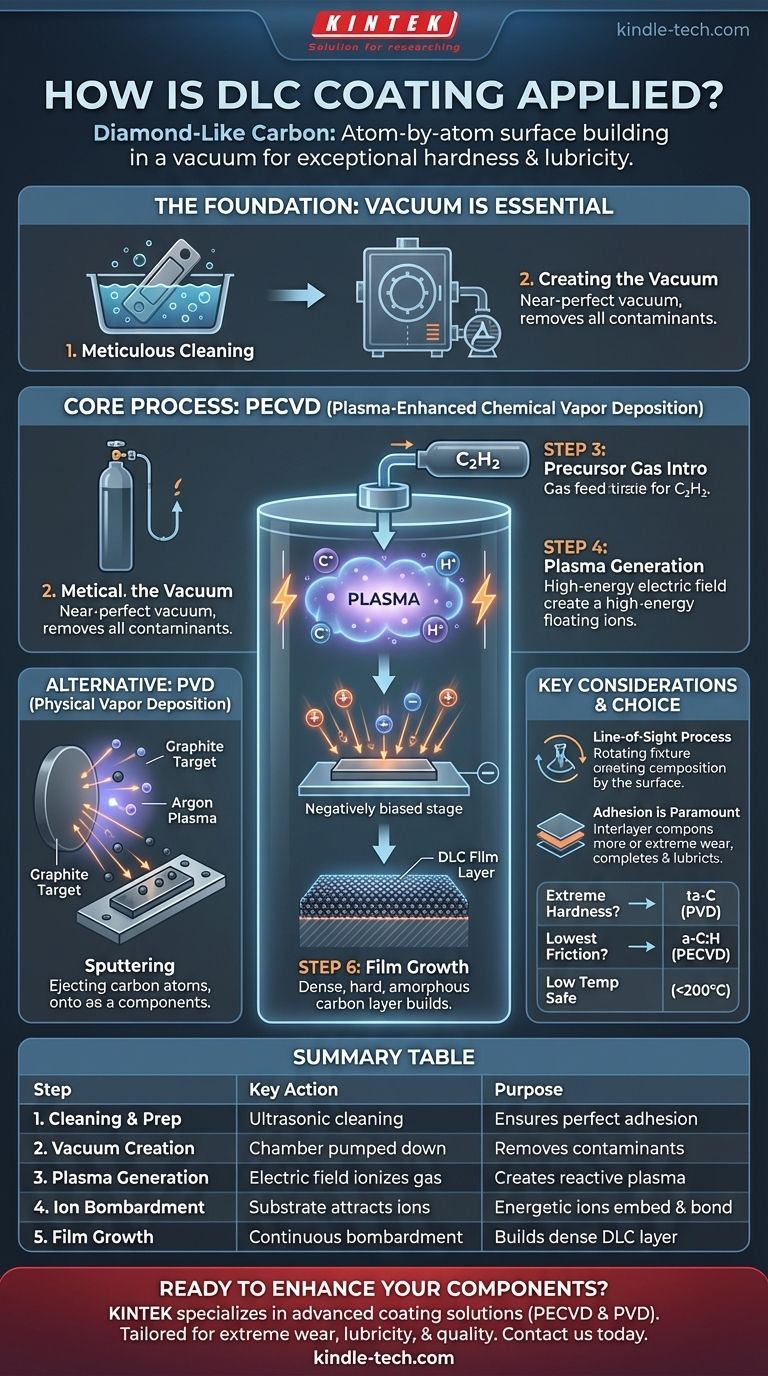

In essence, a Diamond-Like Carbon (DLC) coating is applied using a vacuum chamber process where a high-energy plasma is created from a hydrocarbon source. This plasma breaks down the source material into carbon and hydrogen ions, which are then accelerated and deposited onto the target component's surface. As these ions bombard the surface, they bond and "recombine" to form an extremely hard, dense, and smooth amorphous carbon layer with diamond-like properties.

The core principle is not painting or plating, but rather building a new surface, atom by atom. A high-energy vacuum process transforms a gas into a solid film that is atomically bonded to the component, granting it exceptional hardness and lubricity.

The Foundation: Why a Vacuum is Essential

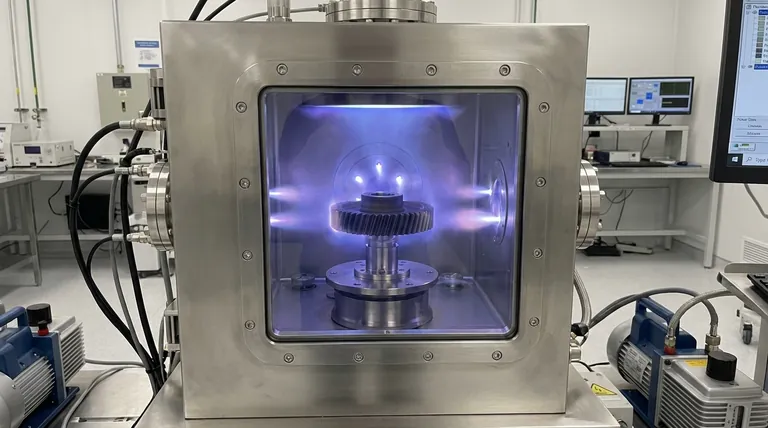

Before any coating can be applied, the process must take place in a controlled environment. The entire deposition process occurs inside a sealed vacuum chamber.

Step 1: Meticulous Cleaning

The single most critical factor for a successful coating is the cleanliness of the substrate. Any oil, grease, or microscopic contaminant will prevent the DLC film from bonding properly, leading to poor adhesion and failure. Parts undergo a multi-stage, often ultrasonic, cleaning process.

Step 2: Creating the Vacuum

The prepared components are loaded into the chamber, which is then pumped down to a near-perfect vacuum. This removes all atmospheric gases and potential contaminants, ensuring the only atoms present are the ones intentionally introduced for the coating process.

The Core Process: Plasma-Enhanced Chemical Vapor Deposition (PECVD)

The method described by your source is a form of PECVD, one of the most common ways to apply DLC. It uses a precursor gas as the source for the carbon atoms.

Step 3: Introducing the Precursor Gas

A precise amount of a hydrocarbon gas, such as acetylene (C₂H₂), is introduced into the vacuum chamber. This gas contains the essential carbon and hydrogen atoms needed to form the coating.

Step 4: Generating the Plasma

A powerful electric field is applied within the chamber. This immense energy strips electrons from the gas molecules, breaking them apart and creating a glowing, ionized gas known as plasma. This plasma is a highly reactive soup of carbon ions, hydrogen ions, and other molecular fragments.

Step 5: Deposition via Ion Bombardment

The component to be coated (the substrate) is given a negative electrical bias. This attracts the positively charged ions from the plasma, causing them to accelerate and bombard the surface with significant energy. This is the "spraying" action your source describes.

Step 6: Film Growth

As the energetic carbon and hydrogen ions strike the surface, they embed themselves and form strong covalent bonds with the substrate and with each other. This continuous bombardment builds the DLC film layer by layer, creating a dense, hard, and atomically smooth amorphous structure.

An Alternative Method: Physical Vapor Deposition (PVD)

It's important to know that PECVD is not the only method. PVD is another common technique, which starts with a solid material instead of a gas.

How PVD Differs

In a PVD process like sputtering, a solid block of high-purity graphite is used as the target. Instead of a hydrocarbon gas, an inert gas like argon is introduced and ionized to create a plasma. This argon plasma is used to bombard the graphite target, physically knocking off, or "sputtering," carbon atoms which then travel through the vacuum and deposit onto the component.

Understanding the Trade-offs and Key Considerations

Applying a DLC coating is a sophisticated process with specific limitations and benefits that dictate its use.

It is a Line-of-Sight Process

The plasma ions travel in relatively straight lines. This means that any surface that is "hidden" or has deep, complex internal geometries will not receive a uniform coating. Parts often need to be mounted on complex fixtures that rotate during the process to ensure even coverage.

Adhesion is Paramount

The DLC film is incredibly hard, but it is only as durable as its bond to the material underneath. Often, a very thin "interlayer" of a different material, like chromium or silicon, is deposited first to act as an atomic glue between the substrate and the final DLC layer.

Not All DLC is the Same

By controlling the process parameters—such as the amount of hydrogen in the precursor gas or the energy of the plasma—engineers can fine-tune the final properties. This results in different types of DLC, from hydrogenated versions (a-C:H) that are extremely slick to hydrogen-free versions (ta-C) that are exceptionally hard.

Making the Right Choice for Your Goal

The method and type of DLC are chosen based on the desired outcome for the component.

- If your primary focus is extreme hardness and wear resistance: A hydrogen-free (ta-C) DLC, often applied via a PVD arc process, is typically the superior choice.

- If your primary focus is the lowest possible friction (lubricity): A hydrogenated (a-C:H) DLC applied via PECVD is often the most effective and economical solution.

- If your component is sensitive to high temperatures: All DLC processes are considered "low temperature" (typically under 200°C), making them safe for heat-treated steels and other sensitive materials.

Ultimately, understanding how DLC is applied reveals that it is a precise engineering process designed to fundamentally enhance a material's surface properties.

Summary Table:

| Process Step | Key Action | Purpose |

|---|---|---|

| 1. Cleaning & Prep | Ultrasonic cleaning of substrate | Ensures perfect adhesion by removing contaminants |

| 2. Vacuum Creation | Chamber is pumped down | Removes atmospheric gases and contaminants |

| 3. Plasma Generation | Electric field ionizes precursor gas | Creates reactive plasma of carbon/hydrogen ions |

| 4. Ion Bombardment | Negatively biased substrate attracts ions | Energetic ions embed and bond to the surface |

| 5. Film Growth | Continuous ion bombardment | Builds a dense, hard, amorphous carbon layer atom by atom |

Ready to enhance your components with a high-performance DLC coating?

At KINTEK, we specialize in advanced coating solutions for laboratories and manufacturers. Our expertise in PECVD and PVD processes ensures your parts gain the exact surface properties you need—whether it's for extreme wear resistance, superior lubricity, or corrosion protection.

We provide:

- Tailored Coating Solutions: Choose from hydrogenated (a-C:H) for low friction or hydrogen-free (ta-C) for maximum hardness.

- Precision and Quality: Our controlled vacuum processes guarantee uniform, adherent coatings on even the most complex geometries.

- Expert Support: From material selection to post-coating analysis, our team is here to ensure your project's success.

Contact us today to discuss how a KINTEK DLC coating can solve your wear and friction challenges.

Get a Quote & Discuss Your Project

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- What is the role of a plasma reactor in cobalt ferrite synthesis? Enhance Magnetic Performance with Plasma Processing

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- How do vacuum pumps and pressure control systems ensure the consistency of thin films in PECVD? Master Film Uniformity

- How is DLC deposited? A Guide to PVD vs. PACVD Methods for Superior Coatings

- What are the advantages of DLC coating? Achieve Superior Hardness, Low Friction & Corrosion Resistance

- What are the different types of plasma sources? A Guide to DC, RF, and Microwave Technologies

- What are the improvements and applications of HDPCVD? Solve High-Aspect-Ratio Gap Filling in Semiconductors

- Where is PECVD used? Unlocking Low-Temperature Thin Film Deposition for Advanced Materials