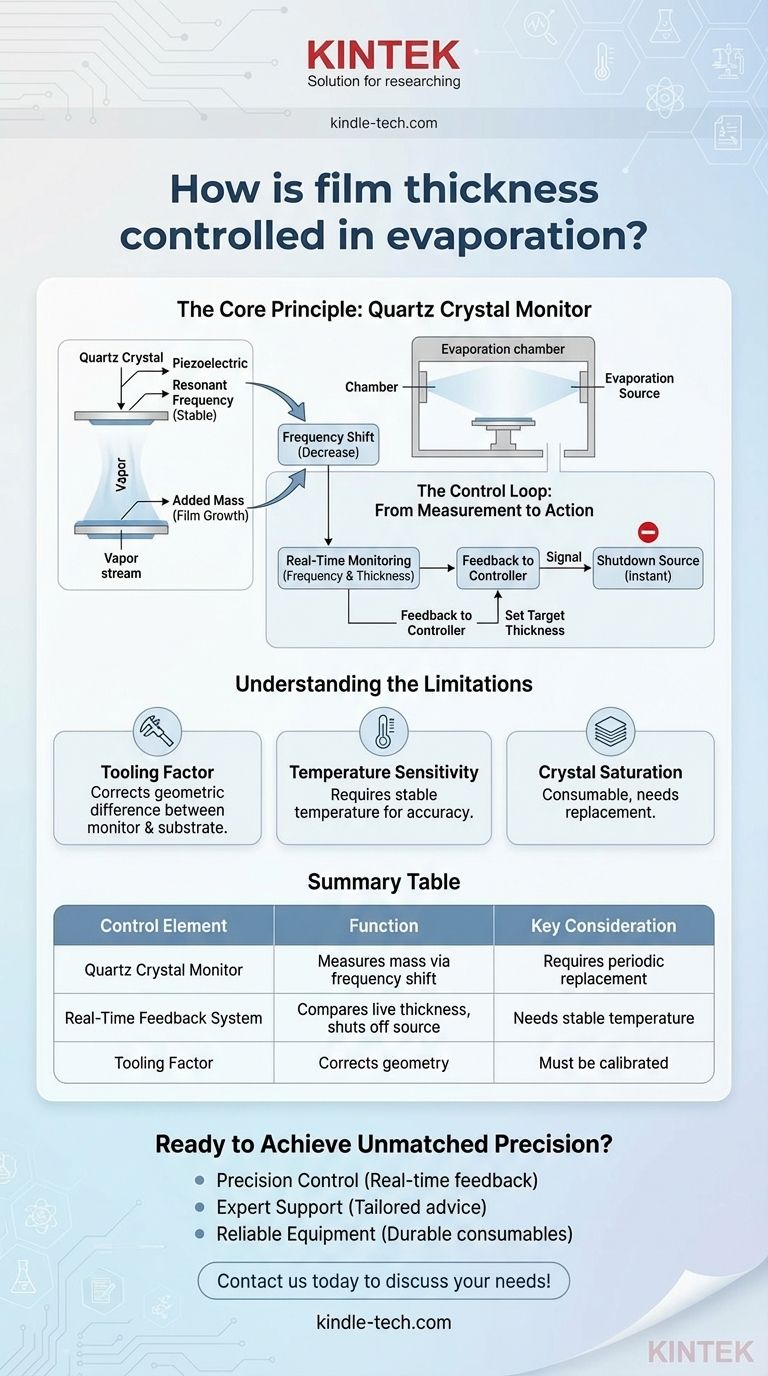

To control film thickness in evaporation, a real-time feedback system is used, centered around a device called a quartz crystal monitor. This monitor measures the rate of film growth as it happens and signals the evaporation source to shut off the instant the desired thickness is achieved, allowing for precision down to the nanometer scale.

The core principle is elegant: A quartz crystal vibrates at a specific frequency. As evaporated material coats the crystal, its mass increases, causing the vibration frequency to decrease. This change in frequency is precisely measured and converted into a film thickness measurement in real-time.

The Principle: How Mass Becomes a Measurement

The effectiveness of this technique relies on the unique properties of quartz crystal and a direct relationship between mass and frequency. Understanding this principle is key to trusting the process.

The Piezoelectric Effect

A quartz crystal is piezoelectric, meaning it physically deforms when a voltage is applied. By applying an alternating voltage, the crystal can be made to oscillate, or vibrate, at a very stable and predictable frequency.

Establishing a Resonant Frequency

Every quartz crystal monitor has a natural, stable resonant frequency. This frequency serves as the baseline—the "zero point"—before any material deposition begins.

The Impact of Added Mass

During evaporation, the stream of vaporized material coats everything inside the chamber, including the surface of the quartz crystal. This minuscule addition of mass makes the crystal heavier.

A heavier object vibrates more slowly than a lighter one. Therefore, as the film grows on the crystal, its resonant frequency begins to decrease in a highly predictable way.

From Frequency Shift to Thickness

The system continuously measures this drop in frequency. The change in frequency is directly proportional to the mass of the material that has been deposited onto the crystal's face.

Knowing the density of the material being evaporated, the system controller can instantly calculate the film's thickness from this mass measurement.

The Control Loop: From Measurement to Action

The measurement itself is only half the process. Its true power comes from how it's used to actively control the deposition.

Real-Time Process Monitoring

This frequency measurement is not a post-process check. It happens live, moment by moment, providing an instantaneous reading of the film's thickness and the rate at which it is growing.

The Feedback Mechanism

The output from the quartz crystal monitor is fed directly into the evaporation system's main controller. The user pre-sets a target thickness for the film.

Triggering the Shutdown

The controller constantly compares the real-time thickness measurement to the target thickness. The moment they match, it sends a signal to shut off the evaporation source (such as an electron beam or a thermal filament), immediately stopping the deposition.

Understanding the Limitations

While incredibly precise, the quartz crystal monitoring method has practical considerations that must be managed for accurate and repeatable results.

The "Tooling Factor"

The crystal monitor is located at a different position than your actual sample (substrate). Due to the geometry of the chamber, the amount of material deposited on the monitor may be slightly different than on the substrate.

A tooling factor is a calibration value used to correct for this geometric difference, ensuring the thickness on your sample is what you truly intend it to be.

Temperature Sensitivity

The resonant frequency of quartz is also sensitive to temperature. Significant temperature fluctuations during the deposition process can introduce errors in the thickness reading. Maintaining a stable process temperature is crucial for accuracy.

Crystal Saturation and Lifetime

The crystal is a consumable component. As more material is deposited over many runs, it becomes so heavy that its oscillation can become unstable or stop altogether. This is known as crystal failure, and the crystal must be replaced periodically to ensure reliable operation.

Making the Right Choice for Your Goal

By understanding these principles, you can move from simply using the equipment to intelligently controlling your deposition process for optimal outcomes.

- If your primary focus is maximum accuracy: You must perform calibration runs to precisely determine the tooling factor for your specific material and chamber geometry.

- If your primary focus is process repeatability: You must prioritize stabilizing all process parameters, especially chamber temperature and the physical placement of the monitor and substrates.

- If your primary focus is reliable operation: You must implement a schedule for monitoring crystal life and replacing crystals proactively before they fail and ruin a deposition run.

Ultimately, mastering thickness control is about turning a physical principle into a precise and repeatable engineering process.

Summary Table:

| Control Element | Function | Key Consideration |

|---|---|---|

| Quartz Crystal Monitor | Measures mass deposition via frequency shift | Requires periodic replacement due to saturation |

| Real-Time Feedback System | Compares live thickness to target, shuts off source | Needs stable temperature for accuracy |

| Tooling Factor | Corrects for geometric differences between monitor and substrate | Must be calibrated for specific chamber setups |

Ready to Achieve Unmatched Precision in Your Thin-Film Deposition?

At KINTEK, we specialize in providing advanced laboratory equipment, including evaporation systems with sophisticated quartz crystal monitoring technology. Whether you're in research, semiconductor manufacturing, or materials science, our solutions ensure nanometer-scale accuracy and repeatable results for all your thin-film applications.

Let us help you optimize your process:

- Precision Control: Achieve exact film thickness with real-time feedback systems.

- Expert Support: Get tailored advice on tooling factor calibration and process stabilization.

- Reliable Equipment: Access durable consumables and monitoring components designed for long-term performance.

Contact us today to discuss your specific lab equipment needs and discover how KINTEK can enhance your evaporation processes!

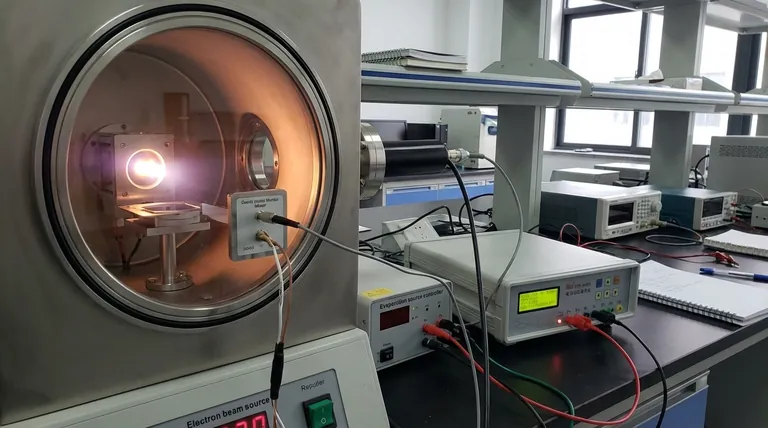

Visual Guide

Related Products

- Battery Lab Equipment Battery Capacity and Comprehensive Tester

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- High Performance Laboratory Freeze Dryer for Research and Development

- Multi Heating Zones CVD Tube Furnace Machine Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- How does the vacuum evaporation system work? A Guide to Thin Film Deposition

- What are two advantages of using sputtering as opposed to evaporation to create a metal interconnect system? Superior Film Quality & Control

- What is the use of electron beam? Harnessing Precision Energy for Industry & Science

- Why does the physical vapor deposition process need to be conducted in a vacuum environment? Ensure Purity and Performance

- What is e-beam evaporation? Achieve High-Purity Thin Film Deposition for Your Lab

- What is the evaporation method of e-beam? Achieve High-Purity Thin Film Coatings

- What is a thin film evaporator? A Gentle Solution for Heat-Sensitive & Viscous Materials

- What is thermal evaporation used to deposit? A Guide to Metals, Compounds, and Key Applications