In the context of direct energy generation, gasification is often considered more advantageous than pyrolysis due to its higher efficiency in converting biomass into a usable energy form. The process is specifically designed to maximize the production of synthesis gas (syngas), a combustible fuel ideal for immediate use in generating electricity and heat. Pyrolysis, by contrast, fractures the feedstock into three separate products—bio-oil, bio-char, and gas—which require distinct and often separate downstream applications.

The choice between gasification and pyrolysis is not a matter of one being universally superior. The "advantage" is entirely dependent on your goal: choose gasification for maximum immediate power generation, and choose pyrolysis for producing storable liquid fuels and valuable solid byproducts.

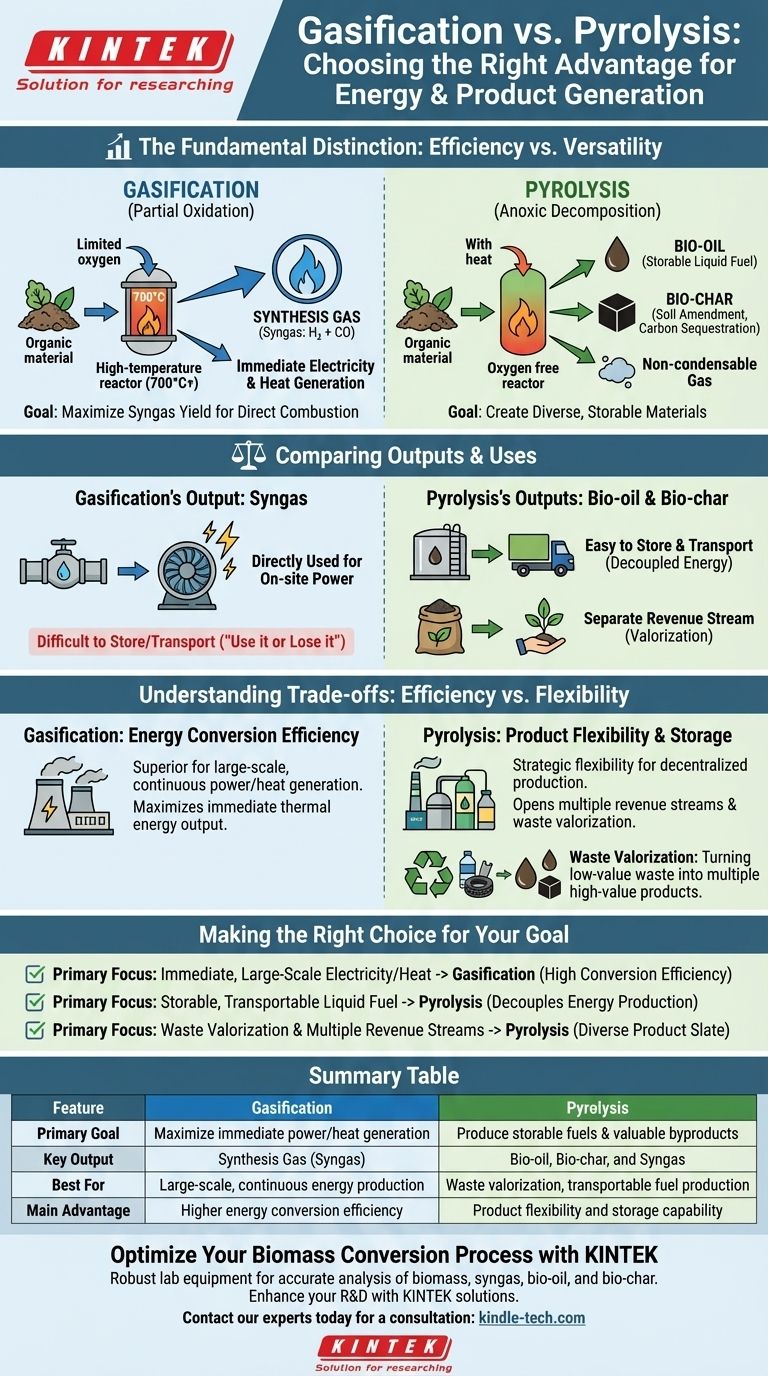

The Fundamental Process Distinction

To understand their respective advantages, you must first recognize that gasification and pyrolysis are engineered for different outcomes. They are not interchangeable processes.

Gasification: Creating a Gaseous Fuel

Gasification exposes organic material to very high temperatures (typically above 700°C) in an environment with a limited and controlled amount of oxygen.

This partial oxidation process is not designed to burn the material, but to break it down and convert it almost entirely into synthesis gas (syngas). Syngas is a mixture composed primarily of hydrogen (H₂) and carbon monoxide (CO).

The goal of gasification is singular: maximize the yield and energy content of this syngas for direct combustion.

Pyrolysis: Deconstructing a Feedstock

Pyrolysis occurs in a completely oxygen-free (anoxic) environment. The absence of oxygen prevents combustion and instead uses heat to thermally decompose the material into its core components.

This process yields three distinct products: a liquid (bio-oil), a solid (bio-char), and a smaller amount of non-condensable gas.

The goal of pyrolysis is product diversification—to create a portfolio of valuable, storable materials from a single feedstock.

Comparing the Primary Outputs and Their Uses

The "better" technology is the one that produces the output that best matches your strategic objective.

Gasification's Output: Synthesis Gas

Syngas is a fuel gas that can be immediately piped to a gas engine or turbine to generate electricity and heat. Its value lies in its direct and efficient utility for on-site power generation.

However, as a gas, syngas is difficult and economically unviable to store or transport over long distances. It is a "use it or lose it" energy source.

Pyrolysis's Outputs: Bio-oil and Bio-char

Bio-oil is an energy-dense liquid. This makes it easy to store and transport, effectively decoupling the energy production from the initial conversion process. It can be refined into transportation fuels or used to produce specialty chemicals.

Bio-char is a stable, carbon-rich solid. It is highly valued as a soil amendment to improve fertility and sequester carbon, representing a separate revenue stream or environmental benefit.

Understanding the Trade-offs: Efficiency vs. Versatility

The core advantage of gasification is its efficiency in a specific application, whereas the advantage of pyrolysis lies in its flexibility.

The Case for Gasification: Energy Conversion Efficiency

For the sole purpose of generating power and heat, gasification is superior. By converting the vast majority of the feedstock's chemical energy into a single, combustible gas, it maximizes the immediate thermal energy output.

This makes it the preferred technology for large-scale, continuous waste-to-energy or biomass-to-power facilities.

The Case for Pyrolysis: Product Flexibility and Storage

Pyrolysis offers strategic flexibility that gasification lacks. The ability to produce a stable, transportable liquid fuel allows for decentralized production, even in remote locations.

Biomass can be processed locally via pyrolysis, and the resulting energy-dense bio-oil can be transported far more cheaply than the original raw biomass. This opens up possibilities for multiple revenue streams from bio-oil, bio-char, and captured chemicals.

The Role of Waste Valorization

Pyrolysis is exceptionally well-suited for the concept of valorization—turning low-value waste into multiple high-value products. It can effectively process mixed waste streams like plastics and tires, recovering valuable materials and creating marketable commodities.

Gasification can also process these wastes, but its primary output remains syngas for energy, not a diverse slate of material products.

Making the Right Choice for Your Goal

The "advantage" of either technology is defined by your project's primary objective. Use these guidelines to make a clear decision.

- If your primary focus is immediate, large-scale electricity or heat generation: Gasification is the more direct and efficient pathway due to its high conversion efficiency into syngas.

- If your primary focus is producing a storable, transportable liquid fuel: Pyrolysis is the clear choice, as its primary liquid output (bio-oil) decouples energy use from its initial production.

- If your primary focus is waste valorization with multiple revenue streams: Pyrolysis is more advantageous because it creates distinct products—bio-oil for fuel/chemicals and bio-char for agriculture—from a single input stream.

Ultimately, understanding that these are two distinct tools for different outcomes is the key to selecting the right technology for your objective.

Summary Table:

| Feature | Gasification | Pyrolysis |

|---|---|---|

| Primary Goal | Maximize immediate power/heat generation | Produce storable fuels & valuable byproducts |

| Key Output | Synthesis Gas (Syngas) | Bio-oil, Bio-char, and Syngas |

| Best For | Large-scale, continuous energy production | Waste valorization, transportable fuel production |

| Main Advantage | Higher energy conversion efficiency for direct use | Product flexibility and storage capability |

Optimize Your Biomass Conversion Process with KINTEK

Whether your project requires the high-efficiency energy generation of gasification or the versatile product slate from pyrolysis, having the right laboratory equipment is crucial for research, development, and quality control. KINTEK specializes in supplying robust and precise lab equipment and consumables tailored for analyzing biomass, syngas, bio-oil, and bio-char.

Let us help you achieve your goals:

- Accurate Syngas Analysis for gasification process optimization.

- Reliable Bio-oil & Bio-char Testing to maximize product value from pyrolysis.

Contact our experts today to discuss how our solutions can enhance your biomass conversion R&D and ensure your process is efficient and effective.

Get in Touch for a Consultation

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Variable Speed Peristaltic Pump

People Also Ask

- What role does an autoclave play in simulating PWR conditions? Advanced Material Validation for Nuclear Safety

- What is the function of a constant temperature hydrothermal reactor? Master Coal Fly Ash Activation

- What roles do autoclaves play in MFI zeolite synthesis? Master Hydrothermal Crystalline Growth

- Why are sealed laboratory reaction vessels necessary in the hydrothermal synthesis of zeolites? Ensure Purity and Yield

- What is the contribution of a hydrothermal reactor to graded pore construction? Precision Templates for TAS