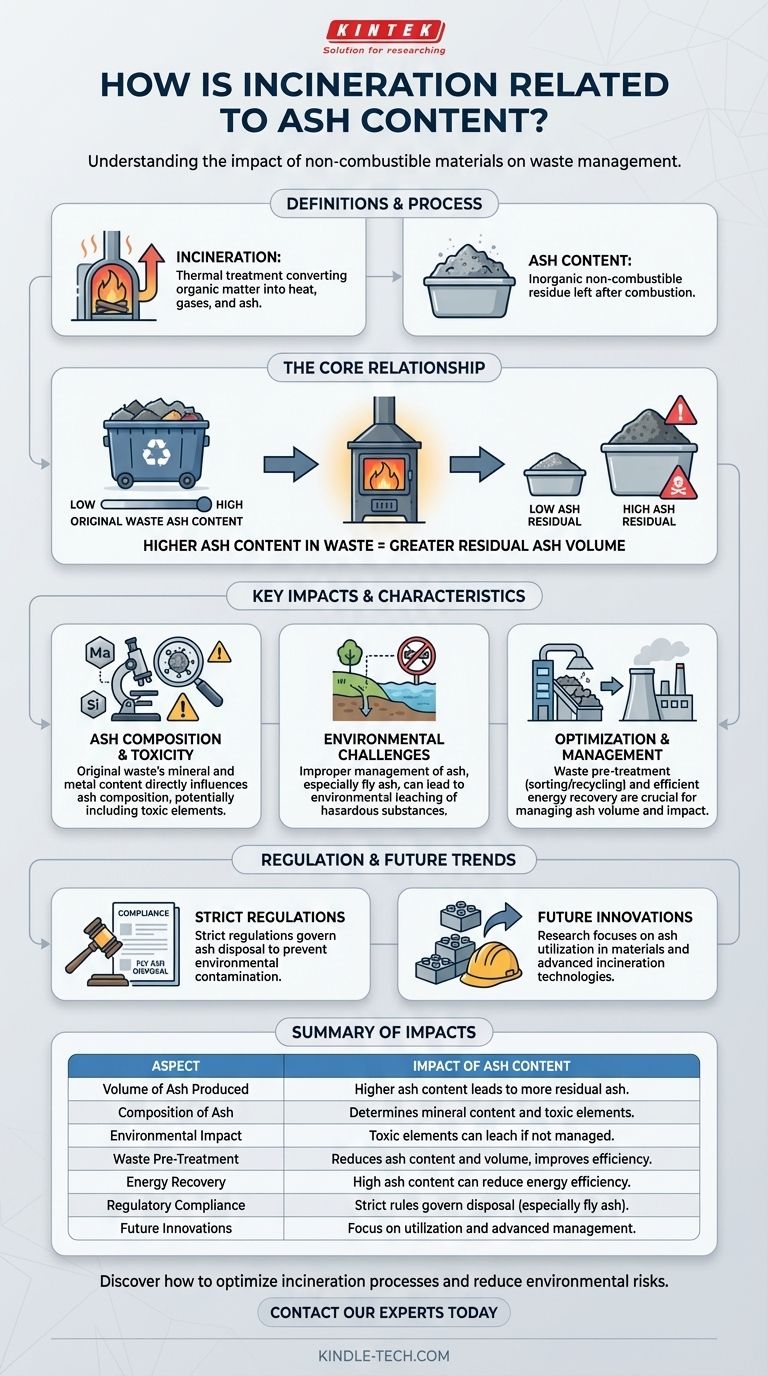

Incineration is a waste treatment process that involves the combustion of organic substances contained in waste materials. This process reduces the volume of waste and generates energy, but it also produces ash as a byproduct. The ash content in waste materials directly influences the amount and characteristics of the ash produced during incineration. Higher ash content in the original waste leads to more residual ash after combustion, which needs to be managed carefully due to its potential environmental impact. The composition of the ash, including its mineral content and potential toxic elements, is also determined by the original waste's ash content. Understanding the relationship between incineration and ash content is crucial for optimizing waste management strategies and minimizing environmental hazards.

Key Points Explained:

-

Definition of Incineration and Ash Content:

- Incineration: A thermal treatment process where waste materials are burned at high temperatures, converting organic matter into heat, gases, and ash.

- Ash Content: The inorganic residue left after the combustion of organic materials. It is a measure of the non-combustible portion of the waste.

-

Relationship Between Ash Content and Incineration:

- Volume of Ash Produced: The higher the ash content in the original waste, the greater the volume of ash that will remain after incineration. This is because ash content represents the non-combustible portion of the waste.

- Composition of Ash: The mineral content and potential toxic elements in the ash are directly influenced by the original waste's ash content. For example, waste with high metal content will produce ash with higher concentrations of metals.

-

Environmental Impact of Ash:

- Toxic Elements: Ash from incineration can contain heavy metals and other toxic substances, which can leach into the environment if not properly managed.

- Disposal and Management: The management of ash is a critical aspect of incineration. It often requires stabilization or treatment to prevent environmental contamination.

-

Optimizing Incineration Processes:

- Waste Pre-Treatment: Reducing the ash content in waste before incineration can minimize the volume of ash produced. This can be achieved through sorting and recycling processes.

- Energy Recovery: Efficient incineration processes can recover energy from waste, but the presence of high ash content can affect the efficiency of energy recovery.

-

Regulatory and Safety Considerations:

- Regulations: There are strict regulations governing the disposal of incineration ash, particularly fly ash, which is more likely to contain hazardous substances.

- Safety Measures: Proper handling and disposal of ash are essential to protect workers and the environment from potential hazards.

-

Future Trends and Innovations:

- Ash Utilization: Research is ongoing into ways to utilize incineration ash, such as in construction materials, which could reduce the need for landfill disposal.

- Advanced Incineration Technologies: New technologies aim to reduce the environmental impact of incineration, including better control of emissions and more efficient ash management.

Understanding the relationship between incineration and ash content is essential for developing effective waste management strategies that minimize environmental impact while maximizing resource recovery.

Summary Table:

| Aspect | Impact of Ash Content |

|---|---|

| Volume of Ash Produced | Higher ash content in waste leads to more residual ash after incineration. |

| Composition of Ash | Determines mineral content and toxic elements, influenced by the original waste's ash. |

| Environmental Impact | Toxic elements in ash can leach into the environment if not managed properly. |

| Waste Pre-Treatment | Reducing ash content before incineration minimizes ash volume and improves efficiency. |

| Energy Recovery | High ash content can reduce energy recovery efficiency during incineration. |

| Regulatory Compliance | Strict regulations govern ash disposal, especially for hazardous fly ash. |

| Future Innovations | Research focuses on ash utilization and advanced technologies for better ash management. |

Discover how to optimize incineration processes and reduce environmental risks—contact our experts today!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How are muffle or tube furnaces used in stainless steel creep research? Expert Insights for Precision Thermal Aging

- Why are high-temperature sintering furnaces necessary for ceramic breeder particles? Optimize Fusion Blanket Performance

- What are the applications of dry ashing? A Guide to Precise Mineral Analysis

- Why is a high-temperature muffle furnace required for the sintering of lithium-based tritium breeding ceramics? Optimize Density

- How does a high-temperature muffle furnace facilitate phase transformation in MWCNTs/TiO2? Enhance Your Material Research

- How does a high-temperature muffle furnace facilitate the control of crystalline phase transformations in TiO2?

- What does heat treatment do to materials? Unlock Strength, Durability, and Performance

- What are the primary functions of a high-temperature muffle furnace in CaO catalyst production? Master Biodiesel Efficiency