At its core, torrefaction and slow pyrolysis are both thermochemical processes that heat biomass in the absence of oxygen, but they operate at different temperatures to achieve fundamentally different goals. Torrefaction is a mild "roasting" process (200-300°C) designed to upgrade solid biomass into a high-quality, coal-like fuel, prioritizing a high mass and energy yield in the solid product. Slow pyrolysis is a more intense "charring" process (>300°C) intended to maximize the production of stable, carbon-rich biochar for agricultural or specialty uses.

The critical distinction is one of intent. Choose torrefaction when your goal is to create a better solid fuel. Choose slow pyrolysis when your goal is to create a stable solid carbon product (biochar).

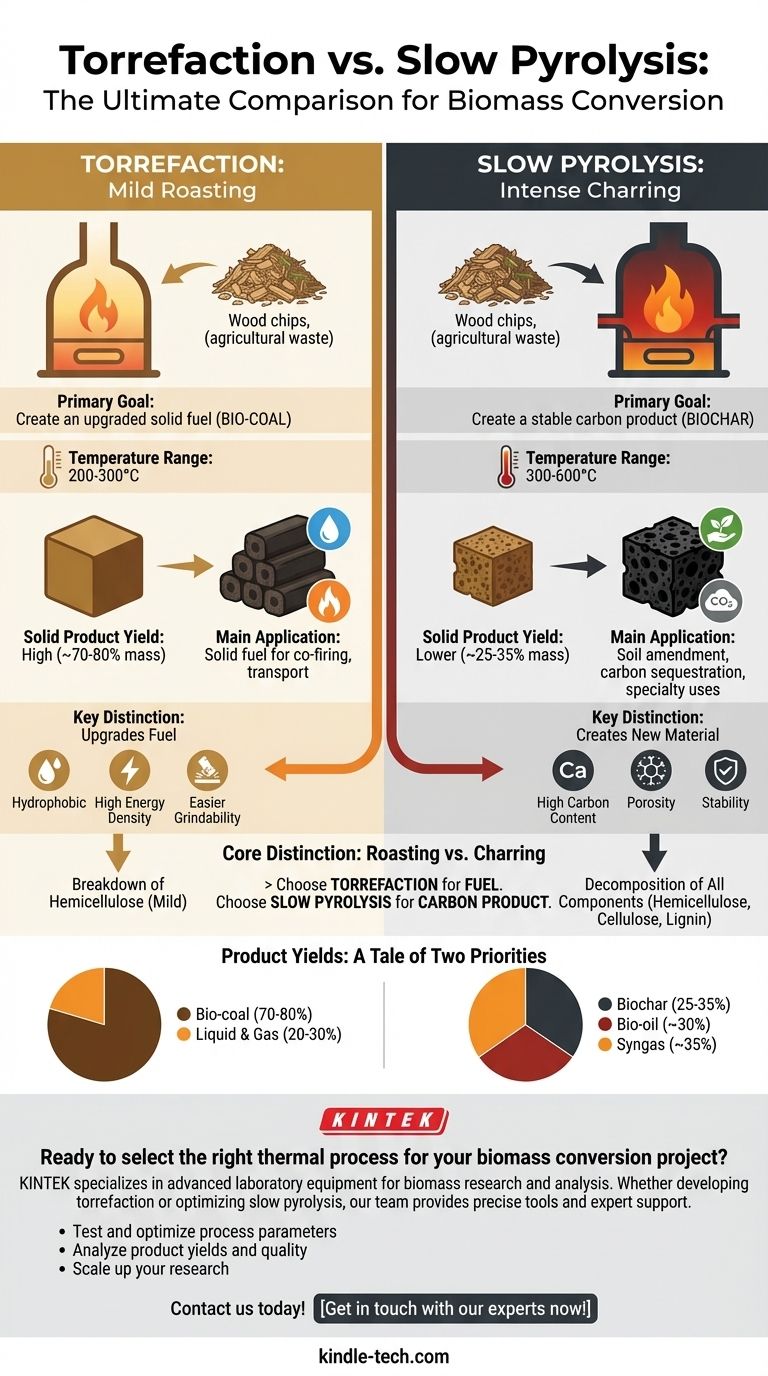

The Core Distinction: Roasting vs. Charring

The difference between these two technologies is best understood by their intended outcomes. One aims to improve a fuel, while the other aims to create a new material.

Torrefaction: Upgrading a Solid Fuel

Torrefaction is essentially a low-temperature heat treatment. Its primary purpose is to improve the physical and chemical properties of raw biomass, making it a better substitute for coal.

The resulting product, torrefied biomass or bio-coal, is hydrophobic (water-resistant), has a higher energy density, and is far easier to grind and transport than the original feedstock. The process targets the breakdown of hemicellulose while leaving most of the cellulose and lignin intact.

Slow Pyrolysis: Creating Stable Biochar

Slow pyrolysis operates at higher temperatures and is designed to thermally decompose all of the biomass components (hemicellulose, cellulose, and lignin).

While it also produces liquid (bio-oil) and gaseous (syngas) products, the "slow" heating rate and longer processing time are optimized to maximize the yield of the solid residue, biochar. This material is valued not for its fuel properties but for its high carbon content, porosity, and stability, making it ideal for soil amendment and carbon sequestration.

Key Process Parameters Compared

The different goals of torrefaction and pyrolysis dictate different operating conditions. The temperature is the most significant variable.

Operating Temperature: The Defining Factor

Temperature directly controls which components of the biomass break down.

- Torrefaction (200-300°C): This range is high enough to drive off water and decompose the volatile, low-energy hemicellulose component of the biomass. This is what improves the fuel quality.

- Slow Pyrolysis (300-600°C): This higher temperature range is required to fully break down the more resilient cellulose and lignin, converting them into a stable, aromatic carbon structure (biochar).

Product Yields: A Tale of Two Priorities

The final distribution of solid, liquid, and gas products reveals the different priorities of each process.

-

Torrefaction Yields:

- Solid (Bio-coal): ~70-80% mass yield. The goal is to keep as much mass as possible.

- Liquid & Gas: ~20-30% yield. These are often burned to provide heat for the process itself.

-

Slow Pyrolysis Yields:

- Solid (Biochar): ~25-35% mass yield.

- Liquid (Bio-oil): ~30% mass yield.

- Gas (Syngas): ~35% mass yield.

Torrefaction sacrifices a small amount of mass to significantly upgrade the majority. Slow pyrolysis converts the majority of the mass into a distribution of new products.

Understanding the Trade-offs

Choosing between these processes involves clear trade-offs related to energy, complexity, and final application.

Energy Yield vs. End-Use

In torrefaction, about 90% of the initial energy content of the biomass is retained in the solid bio-coal. This makes it an extremely efficient way to produce a solid fuel.

In slow pyrolysis, the energy is distributed across the three product streams (biochar, bio-oil, syngas). The value is not in a single energy product but in the unique properties of the biochar and the potential use of the co-products.

Process Complexity and Cost

Torrefaction operates at lower temperatures, generally requiring less energy input and simpler reactor designs. Its focus on a single primary product simplifies downstream processing.

Slow pyrolysis requires higher temperatures and must manage three distinct product streams (solid, liquid, gas), which adds significant complexity and cost to the overall system for separation, collection, and storage.

Application Mismatches

Using the wrong product for a given application leads to inefficiency. Torrefied biomass is not a good soil amendment because it is not as stable or porous as biochar. Conversely, using high-value biochar simply as a fuel is an economic waste of its unique structural properties.

Making the Right Choice for Your Goal

The decision to use torrefaction or slow pyrolysis should be driven entirely by your end-product requirements.

- If your primary focus is producing a dense, water-resistant solid fuel to co-fire in coal plants or for easier transport: Your clear choice is torrefaction to create bio-coal.

- If your primary focus is creating a stable, porous carbon product for soil improvement, carbon sequestration, or specialty material applications: Your clear choice is slow pyrolysis to create biochar.

- If your primary focus is maximizing the liquid fuel (bio-oil) yield from biomass: You should investigate a third process, fast pyrolysis, which uses even higher heating rates to achieve this specific goal.

Understanding this fundamental difference in purpose is the key to selecting the optimal thermal process for your biomass conversion goals.

Summary Table:

| Feature | Torrefaction | Slow Pyrolysis |

|---|---|---|

| Primary Goal | Create an upgraded solid fuel (bio-coal) | Create a stable carbon product (biochar) |

| Temperature Range | 200-300°C | 300-600°C |

| Solid Product Yield | High (~70-80% mass) | Lower (~25-35% mass) |

| Main Application | Solid fuel for co-firing, transport | Soil amendment, carbon sequestration, specialty uses |

| Process Complexity | Lower temperature, simpler | Higher temperature, manages multiple product streams |

Ready to select the right thermal process for your biomass conversion project?

At KINTEK, we specialize in advanced laboratory equipment for biomass research and analysis. Whether you are developing torrefaction processes to create efficient biofuels or optimizing slow pyrolysis for high-quality biochar production, our team can provide the precise tools and expert support you need.

We help our laboratory customers:

- Test and optimize process parameters with reliable, high-performance reactors and furnaces.

- Analyze product yields and quality with accurate measurement and characterization equipment.

- Scale up your research from bench-top to pilot-scale with robust and customizable systems.

Contact us today to discuss your specific application and discover how KINTEK's solutions can accelerate your biomass innovation. Get in touch with our experts now!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How is a high-temperature calcination furnace utilized in BZY20 Sol-gel? Achieve Pure Cubic Perovskite Phases

- What are the advantages of using a rotary tube furnace for MoVOx catalysts? Elevate Uniformity and Crystallinity

- What temperature is needed for pyrolysis waste? A Guide to Optimizing Your Waste-to-Value Process

- What are the process advantages of using a rotary tube furnace for WS2 powder? Achieve Superior Material Crystallinity

- What are the equipment requirements for loading platinum (Pt) onto composite supports? Precise Stirring for High Dispersion