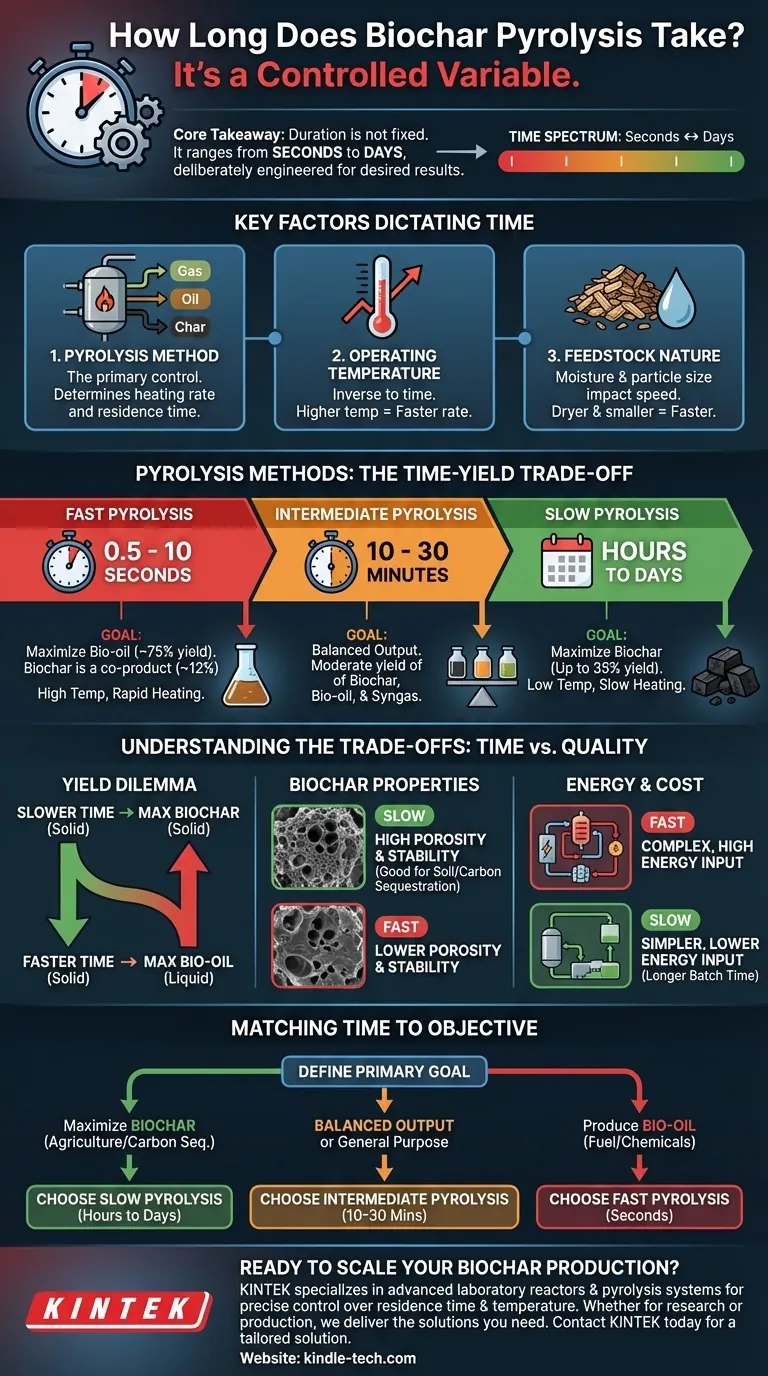

At its core, the process of biochar pyrolysis can take anywhere from a few seconds to several days. This vast range exists because the duration is not a fixed number but a critical variable that is deliberately controlled. The specific time depends entirely on the technology used and the desired properties of the final biochar product.

The essential takeaway is that pyrolysis time is a tool, not a constant. Shorter durations are engineered for liquid fuel production (bio-oil), while longer durations are used to maximize the yield and stability of the solid biochar itself.

The Core Factors That Dictate Pyrolysis Time

The duration that feedstock spends at reaction temperature, known as residence time, is the most direct answer to your question. This time is determined by three interconnected factors: the pyrolysis method, the operating temperature, and the nature of the feedstock.

Pyrolysis Method: The Primary Control

The most significant factor is the type of pyrolysis system being used. These are generally categorized by their heating rate and residence time.

- Slow Pyrolysis: This method, as the name implies, is a long-duration process. Residence times range from several hours to days. It uses lower temperatures and slow heating rates to maximize the production of biochar, yielding up to 35% solid char by weight.

- Fast Pyrolysis: This is an extremely rapid process with residence times of 0.5 to 10 seconds. It uses high temperatures and very fast heating rates. The primary goal of fast pyrolysis is to produce liquid bio-oil (up to 75% yield), with biochar being a secondary co-product (around 12% yield).

- Intermediate Pyrolysis: This method is a balance between the two extremes. Residence times are typically in the range of 10 to 30 minutes, producing more balanced quantities of biochar, bio-oil, and syngas.

Temperature and Heating Rate

Temperature and time are inversely related. To achieve a complete chemical transformation in a shorter time, you need a higher temperature and a faster heating rate.

Slow pyrolysis operates at relatively lower temperatures (around 400°C), allowing the feedstock to "cook" and convert to char over a long period. Fast pyrolysis requires much higher temperatures (often above 500°C) and sophisticated reactors to transfer that heat into the feedstock almost instantaneously.

Feedstock Type and Preparation

The material you are converting into biochar also plays a crucial role in determining the necessary time.

- Moisture Content: Wet feedstock requires a significant amount of initial energy and time just to boil off the water before pyrolysis can even begin. Drier feedstock will convert much more quickly.

- Particle Size: Smaller particles, like sawdust or fine wood chips, have a large surface-area-to-volume ratio. They heat up very quickly and uniformly, enabling short residence times. A large, dense log would require many hours or even days for heat to penetrate its core.

Understanding the Trade-offs: Time vs. Quality

Choosing a pyrolysis duration is an engineering decision with direct consequences for the final product and the efficiency of the operation. There is no single "best" time; there is only the best time for a specific goal.

The Yield Dilemma: Char vs. Oil

A longer residence time (slow pyrolysis) is the standard method for maximizing the yield of solid biochar. If your goal is to produce as much stable, solid carbon as possible for soil amendment or carbon sequestration, a slower process is superior. A shorter residence time (fast pyrolysis) intentionally limits char formation to maximize the yield of liquid bio-oil.

Biochar Properties: Stability and Porosity

Longer, slower pyrolysis generally produces biochar with a more developed pore structure (porosity) and higher surface area. These qualities are highly desirable for agricultural applications, as they improve soil water retention and provide habitat for beneficial microbes. The stable carbon structures formed during slow pyrolysis are also more resistant to decomposition, making them better for long-term carbon sequestration.

Energy Input and Operational Cost

Fast pyrolysis systems are often more complex and require significant energy input to maintain high temperatures and rapid heating. Slow pyrolysis can often be achieved with simpler, lower-cost technology (like retort kilns or earth mound kilns), though the trade-off is the much longer processing time per batch.

Matching Pyrolysis Time to Your Objective

To select the right process, you must first define your primary goal. The optimal duration is the one that produces the output you value most.

- If your primary focus is maximizing biochar for agriculture or carbon sequestration: Choose slow pyrolysis with a residence time of several hours to days.

- If your primary focus is producing liquid bio-oil for fuel or chemical feedstock: Choose fast pyrolysis with a residence time of a few seconds.

- If your primary focus is a balanced output or a smaller-scale, general-purpose system: Intermediate pyrolysis, with a residence time of 10-30 minutes, offers a practical compromise.

Ultimately, controlling the duration of pyrolysis is how you engineer the exact outcome of your process.

Summary Table:

| Pyrolysis Method | Typical Residence Time | Primary Goal | Biochar Yield |

|---|---|---|---|

| Fast Pyrolysis | 0.5 - 10 seconds | Maximize Bio-Oil | ~12% |

| Intermediate Pyrolysis | 10 - 30 minutes | Balanced Output | Moderate |

| Slow Pyrolysis | Hours to Days | Maximize Biochar | Up to 35% |

Ready to Scale Your Biochar Production?

Navigating the trade-offs between pyrolysis time, yield, and product quality requires the right equipment. KINTEK specializes in advanced laboratory reactors and pyrolysis systems designed for precise control over residence time and temperature.

Whether you're focused on maximizing biochar yield for agricultural research or optimizing bio-oil production for energy applications, our solutions deliver the reliability and data you need.

Let our experts help you select the ideal system for your specific goals. Contact KINTEL today to discuss your project and get a tailored solution.

Visual Guide

Related Products

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Why is chromium coating corrosion resistant? The Power of a Self-Healing Oxide Shield

- What is the process of aluminum sputtering? A Guide to Thin Film Deposition

- What is the chemical vapor deposition of silicon carbide? A Guide to High-Performance SiC Manufacturing

- What is the difference between thick film and thin film? Precision vs. Cost for Your Circuit Design

- What is the difference between CVD and MOCVD? Precision vs. Versatility in Thin-Film Deposition

- How are lab-grown diamonds created by CVD? Unlock the Science of Man-Made Gems

- What are the disadvantages of sputter deposition? Key Limitations in Thin Film Technology

- What is the process of ion beam deposition? Achieve Unmatched Precision in Thin-Film Coating