In industrial applications, there is no single answer to how long a diamond coating lasts. The lifespan can range from mere minutes in an extreme metal cutting operation to decades on a low-friction component. This variability is not a flaw in the technology, but a direct result of the specific type of coating used, the material it's applied to, and the precise demands of the application itself.

The critical takeaway is to stop asking "how long" and start asking "which factors control the lifespan." A diamond coating's longevity is not a fixed property but an outcome determined by the interplay of the coating type, the substrate, and the operational environment.

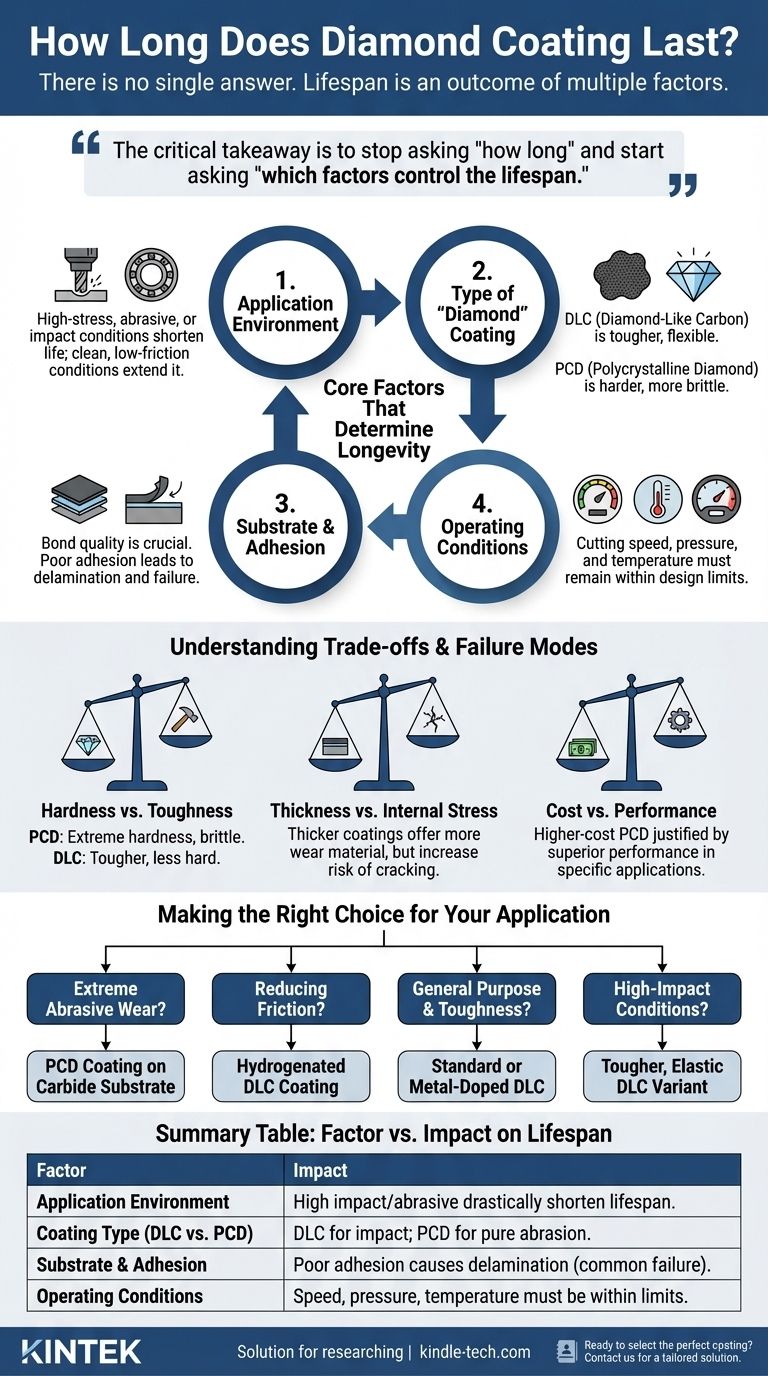

The Core Factors That Determine Longevity

A diamond coating is not a simple layer of paint; it is a highly engineered surface created through complex deposition processes like PVD (Physical Vapor Deposition) or CVD (Chemical Vapor Deposition). Its performance is a function of the entire system.

The Application Environment

The single greatest factor is what the coating is being asked to do. A coating on a cutting tool machining abrasive composites at high speed is under immense stress and will wear faster than one on a bearing surface in a clean, lubricated environment.

High-impact applications can cause chipping, while high-friction applications lead to gradual abrasive wear. Understanding the primary stress—be it impact, abrasion, corrosion, or heat—is the first step.

The Type of "Diamond" Coating

The term "diamond coating" is broad and covers several distinct materials with different properties.

- Diamond-Like Carbon (DLC): This is the most common type. It's an amorphous carbon film that shares properties with natural diamond (like hardness and low friction) but is not crystalline. DLC is generally tougher and more flexible but not as hard as pure diamond.

- Polycrystalline Diamond (PCD): This is a true, crystalline diamond film. PCD is exceptionally hard and offers the ultimate in abrasive wear resistance, but it can be more brittle than DLC and is often applied as a thicker layer.

The choice between the tougher DLC and the harder PCD is a fundamental engineering decision that directly impacts lifespan under specific conditions.

The Substrate and Adhesion

A coating is only as good as its bond to the material underneath, known as the substrate. A perfectly hard coating that peels off the substrate is a complete failure.

Factors like the substrate material (e.g., steel, tungsten carbide, silicon), surface preparation, and the presence of intermediate bonding layers are critical. Poor adhesion is the most common cause of premature coating failure, a phenomenon called delamination.

Operating Conditions

Even within a single application, specific operating conditions matter. For a cutting tool, this includes the cutting speed, feed rate, and the use of coolant. For a wear component, it includes the contact pressure, sliding velocity, and operating temperature. Pushing any of these parameters beyond the coating's design limits will drastically shorten its life.

Understanding the Trade-offs and Failure Modes

There is no universally "best" diamond coating. Every choice involves balancing competing properties, and understanding these trade-offs is essential for managing expectations.

Hardness vs. Toughness

This is the classic materials science trade-off. Hardness is the resistance to scratching and abrasive wear. Toughness is the resistance to chipping or fracturing under impact.

PCD is extremely hard but relatively brittle, making it ideal for pure abrasive wear but vulnerable to high-impact or interrupted cuts. DLC is generally tougher but less hard, giving it an advantage in applications with vibration or impact.

Coating Thickness and Internal Stress

Thicker coatings can provide a longer wear life, but only up to a point. As coatings get thicker, internal stresses can build up, increasing the risk of cracking or delamination.

The optimal thickness is a balance between providing enough wear material and maintaining the integrity and adhesion of the coating film.

Cost vs. Performance

True diamond (PCD) coatings are significantly more expensive to apply than most DLC variants. The investment must be justified by a proportional increase in performance and tool life.

Using a high-cost PCD coating for a light-duty application is an economic waste, just as using a cheap DLC coating in an extreme-wear environment will lead to premature failure and costly downtime.

Making the Right Choice for Your Application

To get a meaningful answer on longevity, you must first define your primary goal. The solution lies in matching the coating system to the specific problem you need to solve.

- If your primary focus is extreme abrasive wear resistance (e.g., machining graphite or metal matrix composites): A true Polycrystalline Diamond (PCD) coating on a rigid carbide substrate is the superior choice.

- If your primary focus is reducing friction and wear on moving parts (e.g., bearings, gears, engine components): A low-friction, hydrogenated Diamond-Like Carbon (DLC) coating is often the most effective and economical solution.

- If your primary focus is a balance of toughness and wear for general-purpose tooling (e.g., drilling aluminum, forming): A standard or metal-doped DLC provides a robust, cost-effective performance boost.

- If your primary focus is surviving high-impact conditions (e.g., stamping, punching): A tougher, more elastic variant of DLC will likely outperform a more brittle, pure diamond coating.

By defining the challenge with precision, you can select an engineered solution where longevity becomes a predictable and valuable outcome.

Summary Table:

| Factor | Impact on Coating Lifespan |

|---|---|

| Application Environment | High-impact or abrasive conditions drastically shorten lifespan compared to low-friction, clean environments. |

| Coating Type (DLC vs. PCD) | DLC is tougher for impact; PCD is harder for pure abrasion. The choice dictates wear resistance. |

| Substrate & Adhesion | Poor adhesion to the base material causes delamination, the most common failure mode. |

| Operating Conditions | Factors like speed, pressure, and temperature must stay within the coating's design limits. |

Ready to select the perfect diamond coating to maximize your tool or component's lifespan?

At KINTEK, we specialize in advanced lab equipment and consumables, including precision coating solutions. Our experts will help you analyze your specific application—whether it's extreme abrasion, high impact, or friction reduction—to recommend the ideal Diamond-Like Carbon (DLC) or Polycrystalline Diamond (PCD) coating.

Contact us today to discuss your requirements and get a tailored solution that ensures predictable performance and longevity for your laboratory or industrial needs.

#ContactForm

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond Dressing Tools for Precision Applications

- Laboratory CVD Boron Doped Diamond Materials

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability