Ultimately, the time it takes to produce biochar depends entirely on the method used, but the most common approach, slow pyrolysis, requires a residence time of several hours. This process involves heating biomass at lower temperatures (around 400°C) in an oxygen-free environment to deliberately maximize the final yield of the solid biochar itself.

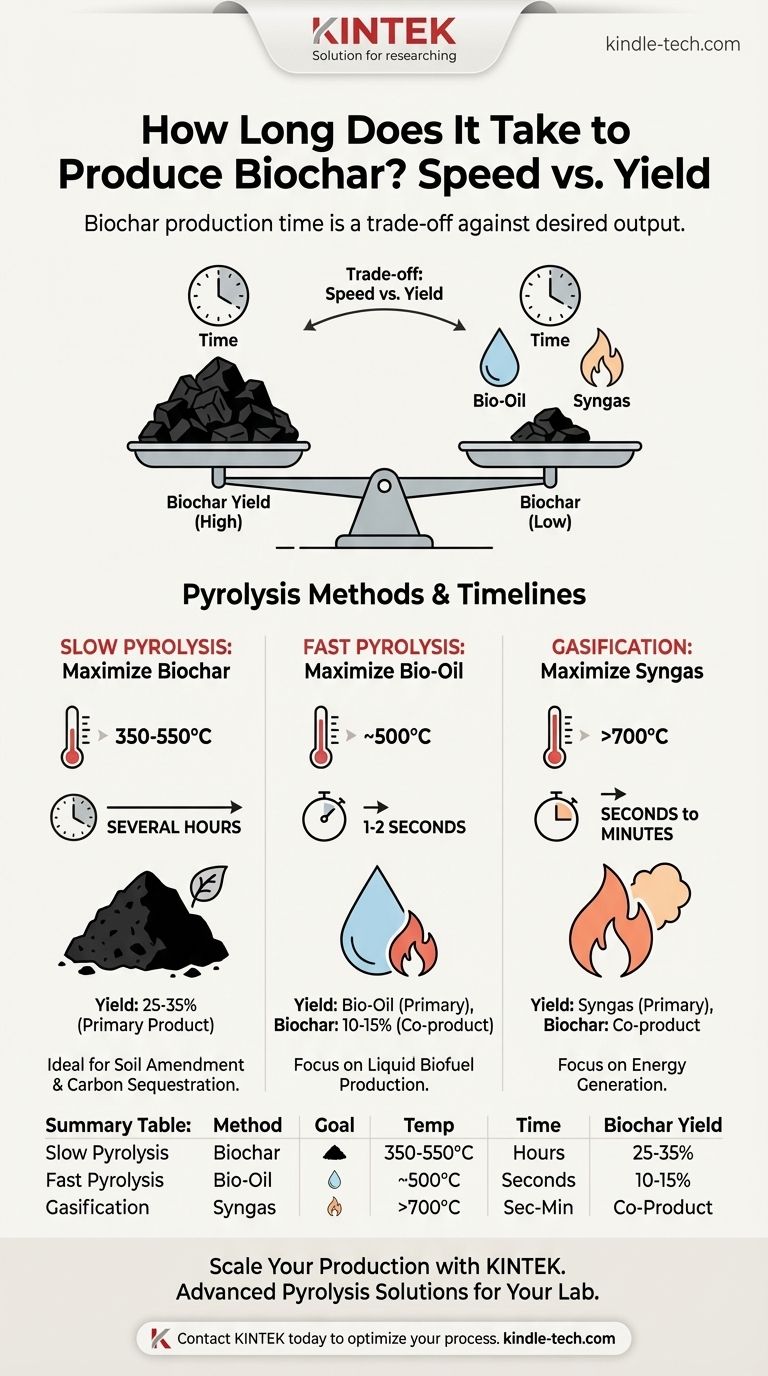

The production time for biochar is not a fixed duration but a critical variable that is traded against the desired output. While traditional methods take hours to maximize biochar yield, faster methods lasting mere seconds exist but prioritize the production of bio-oil or syngas instead.

The Core Process: Understanding Pyrolysis

Pyrolysis is the foundational process for creating biochar. It involves the thermal decomposition of organic material, like wood or agricultural waste, in the absence of oxygen.

The Role of Temperature and Residence Time

The two most important variables in any pyrolysis system are temperature and residence time (how long the biomass is heated). These factors have an inverse relationship and directly determine the final products.

Lower temperatures combined with longer residence times favor the production of a solid char. Conversely, higher temperatures and extremely short residence times favor the production of liquids (bio-oil) and gases (syngas).

Feedstock Preparation is a Prerequisite

Before the heating process can even begin, the raw biomass must be prepared. This involves drying the material to reduce its moisture content and mechanical processing (shredding or grinding) to create a uniform particle size, which ensures consistent heating.

Production Methods and Their Timelines

The term "biochar production" can refer to several distinct processes, each with a vastly different timeline and objective.

Slow Pyrolysis: Maximizing Biochar Yield

This is the most common method when the primary goal is producing biochar for applications like soil amendment or carbon sequestration.

By using lower temperatures (typically 350-550°C) and a long residence time of several hours, the process is optimized to convert the biomass into a stable, carbon-rich solid. This method typically yields 25-35% biochar by mass.

Fast Pyrolysis: Prioritizing Bio-Oil

When the goal is to create liquid biofuel, fast pyrolysis is the preferred method. This process uses higher temperatures (around 500°C) and an extremely short residence time, often just 1-2 seconds.

The rapid heating cracks the organic molecules into vapors, which are then quickly cooled and condensed into a liquid known as bio-oil. Biochar is still a co-product, but the yield is much lower, typically around 10-15%.

Gasification: A High-Temperature Alternative

Gasification uses even higher temperatures (>700°C) with a controlled amount of oxygen or steam. The primary goal is to convert the biomass into a combustible gas mixture called syngas.

The residence time is very short, often a matter of seconds to minutes. Biochar is produced as a co-product, but the focus is on maximizing energy generation from the syngas.

Understanding the Trade-offs: Speed vs. Yield

The choice of production method is a strategic decision based on the desired end product. You are always trading one output for another.

The Time-Yield-Product Triangle

You cannot simultaneously optimize for speed, biochar yield, and bio-oil yield.

- Long Time (Hours): Maximizes solid biochar.

- Short Time (Seconds): Maximizes liquid bio-oil or syngas.

Why Slow Pyrolysis Dominates for Biochar

If your objective is to sequester carbon or improve soil health, you need the stable, solid material itself. Therefore, the slow, hours-long process is the standard because it is purpose-built to maximize the yield and quality of the final biochar product. Faster methods treat biochar as a secondary byproduct, not the main event.

Making the Right Choice for Your Goal

The "correct" production time is the one that aligns with your primary objective.

- If your primary focus is producing high-quality biochar for soil: Opt for slow pyrolysis, accepting a residence time of several hours to maximize solid yield.

- If your primary focus is producing liquid biofuel (bio-oil): Use fast pyrolysis, which drastically reduces production time to seconds but yields significantly less biochar.

- If your primary focus is generating energy from syngas: Consider gasification, which also has a short residence time and produces biochar as a secondary co-product.

Understanding that production time is a direct function of your desired output empowers you to select the right pyrolytic process for your specific application.

Summary Table:

| Method | Primary Goal | Temperature Range | Residence Time | Biochar Yield |

|---|---|---|---|---|

| Slow Pyrolysis | Maximize Biochar | 350-550°C | Several Hours | 25-35% |

| Fast Pyrolysis | Maximize Bio-Oil | ~500°C | 1-2 Seconds | 10-15% |

| Gasification | Maximize Syngas | >700°C | Seconds to Minutes | Co-Product |

Ready to Scale Your Biochar Production?

Selecting the right pyrolysis method is critical for achieving your yield and efficiency goals. The experts at KINTEK specialize in advanced laboratory equipment for pyrolysis research and process development. We can help you optimize your biochar production, whether your focus is on soil amendment, carbon sequestration, or biofuel generation.

Contact KINTEK today to discuss how our solutions can enhance your lab's capabilities and accelerate your biochar projects.

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

People Also Ask

- What is the application of catalytic pyrolysis? Upgrade Waste into High-Value Biofuel & Chemicals

- What is the regeneration temperature of activated carbon? Optimize Your Process with the Right Method

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What are the advantages of rotary kiln furnace? Achieve Superior Uniformity & Efficiency

- What are the advantages of a rotary kiln? Achieve Superior High-Temperature Processing

- What is the temperature of carbon reactivation? Optimize Your Process Between 700°C and 900°C

- What is the feedstock for biochar? A Guide to Choosing the Right Biomass for Your Needs

- What is calcination in short answer? A Guide to High-Temperature Material Transformation