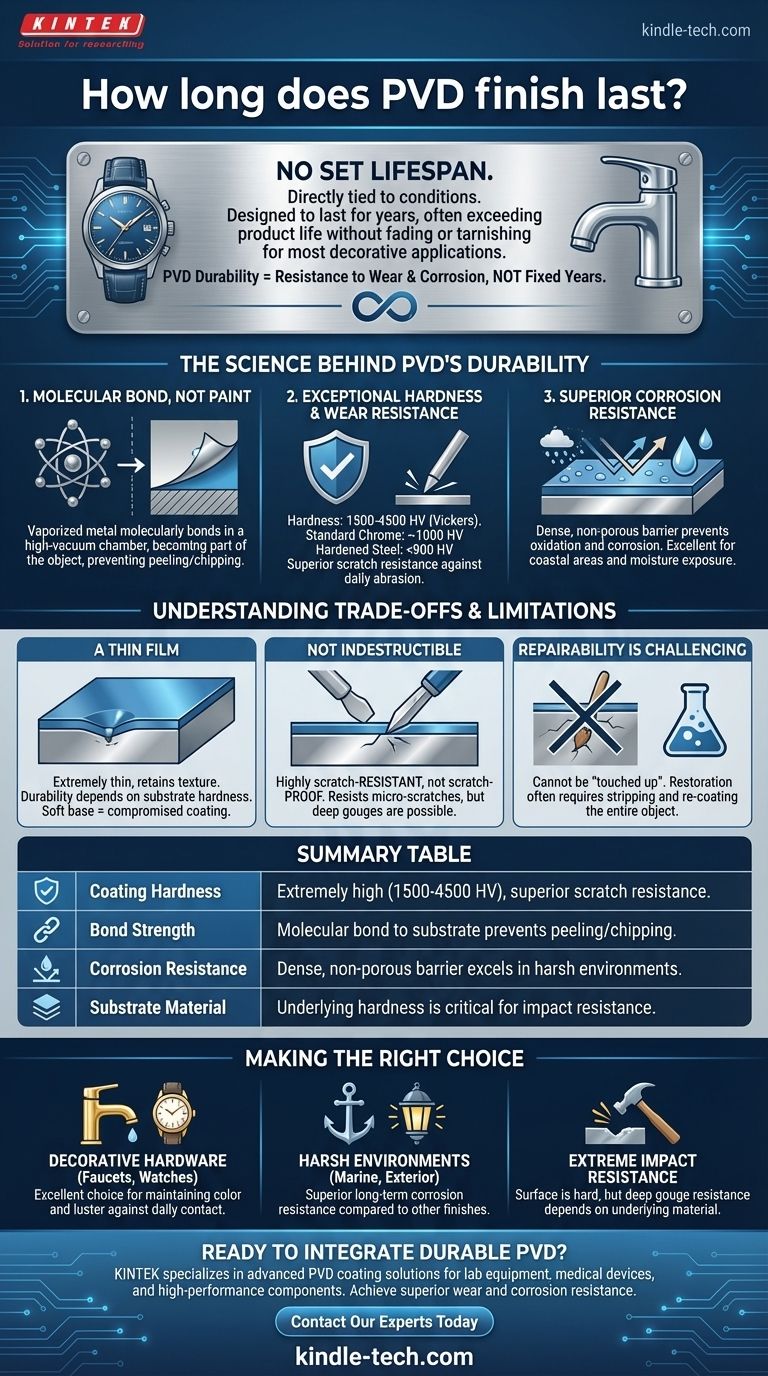

In practice, a PVD finish does not have a set lifespan. Its longevity is directly tied to the conditions it faces. For most decorative and consumer applications, such as on a watch or faucet, a high-quality PVD coating is designed to last for many years, often exceeding the functional life of the product itself without fading or tarnishing.

The durability of a PVD finish isn't measured in a fixed number of years, but rather in its fundamental resistance to wear and corrosion. Its longevity is a direct result of its extreme hardness and the strong molecular bond it forms with the underlying material, making it one of the most durable surface finishes available today.

The Science Behind PVD's Durability

To understand why PVD lasts so long, we need to look beyond the surface and understand the process itself. It's fundamentally different from traditional plating or painting.

A Molecular Bond, Not a Layer of Paint

A PVD coating is not simply applied on top of a surface. The process uses a high-vacuum chamber to vaporize a solid metal, which then molecularly bonds to the substrate.

This creates a finish that is part of the object itself, rather than a separate layer that can easily peel or chip away.

Exceptional Hardness and Wear Resistance

PVD coatings are incredibly hard, which is the primary reason for their superior scratch resistance. Their hardness is typically measured between 1500 and 4500 HV (Vickers).

To put that in perspective, standard chrome plating is around 1000 HV, and hardened steels are often below 900 HV. This exceptional hardness makes PVD finishes highly resistant to the daily abrasion that would degrade lesser coatings.

Superior Corrosion Resistance

The PVD application process creates a very dense, non-porous coating. This barrier is highly effective at preventing oxidation and corrosion.

This is why PVD-coated items perform exceptionally well in harsh environments, such as coastal areas with salt in the air or on fixtures that are frequently exposed to moisture and cleaning chemicals.

Understanding the Trade-offs and Limitations

While PVD is a top-tier finish, it is not invincible. Understanding its limitations is key to using it effectively.

It's a Thin Film

PVD coatings are extremely thin, which allows the product to retain its original texture and shape without softening sharp edges.

However, this means the durability of the finish is also dependent on the hardness of the substrate material. If the base metal is soft and gets dented, the PVD coating can be compromised along with it.

It Is Not Indestructible

While highly scratch-resistant, a PVD finish is not scratch-proof. A sufficiently aggressive attack with a sharp, hard object can gouge the coating.

The key distinction is that it resists the micro-scratches and wear from everyday contact that cause other finishes to look worn and faded over time.

Repairability Can Be a Challenge

Unlike paint, a damaged PVD finish cannot be "touched up." Repairing a significant scratch or gouge is not a simple process.

In most cases, the only way to restore the finish is to chemically strip the entire object and re-coat it, which is often impractical for a consumer product.

Making the Right Choice for Your Application

The suitability of a PVD finish ultimately depends on your specific goal.

- If your primary focus is decorative hardware (faucets, door handles, watches): PVD is an excellent choice that will maintain its original color and luster for many years against daily contact, sweat, and cleaning.

- If your primary focus is components for harsh environments (marine hardware, exterior fixtures): PVD's exceptional corrosion resistance makes it a superior long-term solution compared to most other finishes.

- If your primary focus is extreme impact resistance: Remember that while the surface is hard, the durability against deep gouges depends on the strength of the material underneath the coating.

For its intended applications, a PVD coating offers a level of permanence that few other commercially available finishes can match.

Summary Table:

| Factor | Impact on PVD Longevity |

|---|---|

| Coating Hardness | Extremely high (1500-4500 HV), providing superior scratch resistance. |

| Bond Strength | Molecular bond to substrate prevents peeling and chipping. |

| Corrosion Resistance | Dense, non-porous barrier excels in harsh environments. |

| Substrate Material | Underlying material hardness is critical for impact resistance. |

Ready to integrate a durable, long-lasting PVD finish into your product line? KINTEK specializes in advanced PVD coating solutions for laboratory equipment, medical devices, and high-performance components. Our expertise ensures your products achieve superior wear and corrosion resistance. Contact our experts today to discuss how we can enhance your product's durability and value.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- Why is a heated laboratory hydraulic press necessary for preparing composite laminates with specific fiber orientations?

- What are the advantages and disadvantages of hot stamping? Unlock Ultra-High Strength for Automotive Parts

- What is hot press moulding? Achieve Superior Density and Complex Shapes with Heat and Pressure

- How does hot pressing work? Achieve Maximum Density for Advanced Materials

- What is the advantage by using hot press forming? Achieve Stronger, More Complex Parts