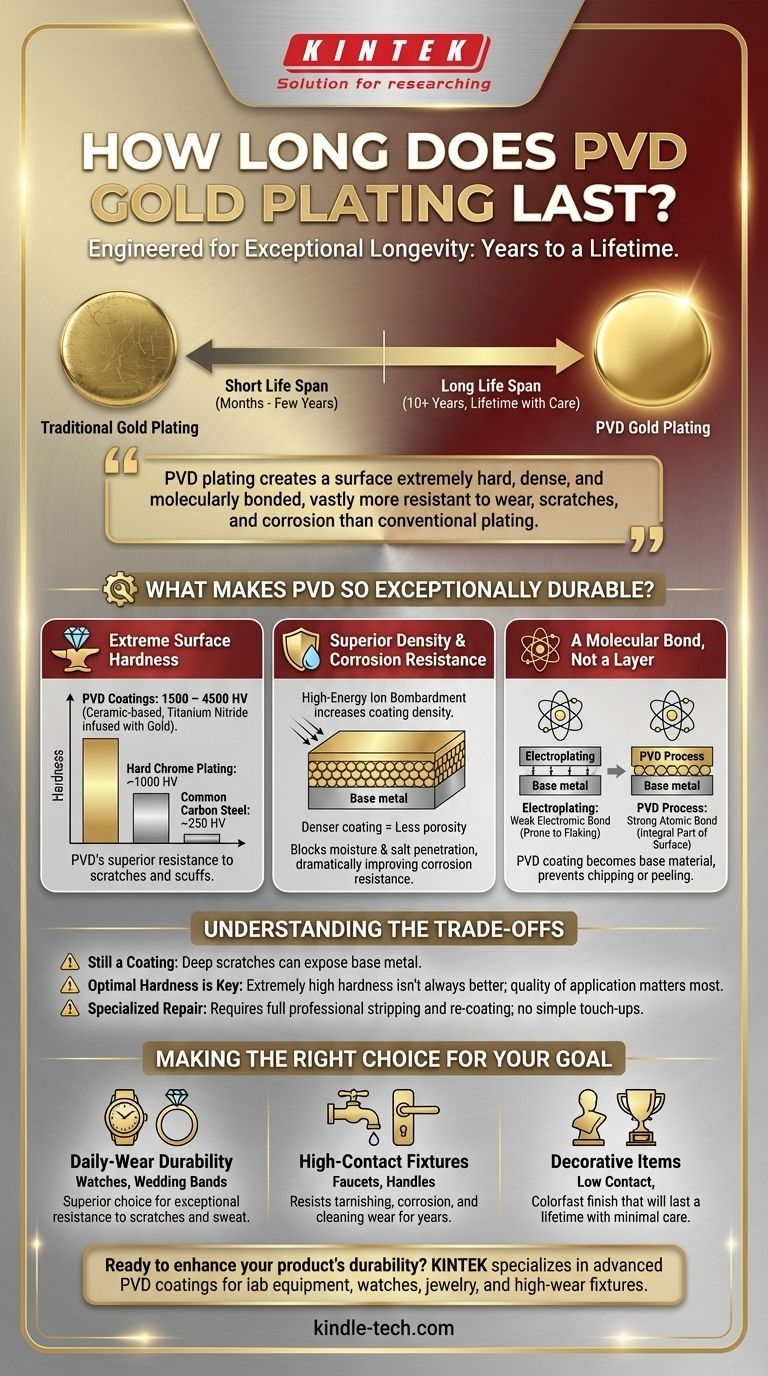

PVD gold plating is engineered for exceptional longevity. Unlike traditional gold plating, a high-quality PVD coating can last for many years—often exceeding a decade and, in some cases, for the lifetime of the item with proper care. Its durability is not measured in microns of gold but in the fundamental toughness of the surface it creates.

The longevity of PVD gold plating is a direct result of the application process itself. By creating a surface that is extremely hard, dense, and molecularly bonded to the base metal, the PVD process produces a finish that is vastly more resistant to wear, scratches, and corrosion than conventional plating methods.

What Makes PVD So Exceptionally Durable?

The term "PVD" stands for Physical Vapor Deposition. Understanding this process is key to understanding why the resulting coating is so resilient. It's a modern surface treatment performed in a high-tech vacuum chamber, not a simple dipping process.

Extreme Surface Hardness

The most significant factor in PVD's lifespan is its incredible hardness. PVD coatings are not just a thin layer of gold; they are a ceramic-based compound, often titanium nitride, infused with gold for color.

This results in a surface that is orders of magnitude harder than traditional materials. PVD coatings have a hardness of 1500 – 4500 HV (Vickers).

To put that in perspective, common carbon steels are around 250 HV, and even hard chrome plating typically maxes out around 1000 HV. This extreme hardness makes PVD-coated surfaces highly resistant to the daily scratches and scuffs that would quickly wear away traditional plating.

Superior Density and Corrosion Resistance

The PVD process involves bombarding the base metal with ions inside the vacuum chamber. This high-energy process doesn't just lay a coating on the surface; it increases the coating's density.

A denser coating has less porosity, meaning there are fewer microscopic holes for moisture or salt to penetrate. This dramatically improves the underlying metal's resistance to corrosion and tarnish.

A Molecular Bond, Not a Layer

Unlike electroplating, which creates a relatively weak electrochemical bond, PVD forms a strong atomic bond between the coating and the base material.

The coating becomes an integral part of the surface itself. This prevents the chipping, flaking, or peeling that is common with older plating methods over time.

Understanding the Trade-offs

While PVD is a superior technology, it's essential to approach it with an objective understanding of its characteristics. No coating is indestructible.

It Is Still a Coating

Despite its durability, a PVD finish is a surface layer. A sufficiently deep or abrasive scratch can still penetrate the coating and expose the base metal underneath, which is typically stainless steel.

Higher Hardness Is Not Always Better

There is an optimal hardness for wear resistance. As the provided research indicates, increasing hardness beyond a certain point can actually be a sign of an improperly applied or brittle coating.

The quality and control of the PVD application process are more critical than simply aiming for the highest hardness number. A reputable manufacturer's process is your best guarantee of quality.

Repair Is a Specialized Process

You cannot "touch up" a damaged PVD coating. If a PVD-coated item is severely damaged, the entire object must have the original coating professionally stripped before being completely re-coated in a specialized PVD facility. This can be costly and is often not feasible for consumer goods.

Making the Right Choice for Your Goal

Your decision should be based on how the item will be used. PVD excels in applications where durability is the primary concern.

- If your primary focus is daily-wear durability (e.g., watches, wedding bands): PVD is the superior choice, offering exceptional resistance to scratches, sweat, and wear that will far outlast traditional plating.

- If your primary focus is a high-contact fixture (e.g., faucets, door handles): PVD provides a finish that resists tarnishing, corrosion, and wear from cleaning and frequent handling for many years.

- If your primary focus is a decorative item with low contact: PVD offers a colorfast finish that will likely last a lifetime, ensuring the piece looks new for decades without polishing or special care.

By understanding that PVD's longevity comes from its advanced engineering process, you can confidently select it for applications where long-term performance is non-negotiable.

Summary Table:

| Key Factor | Why It Matters for Longevity |

|---|---|

| Surface Hardness | PVD coatings (1500-4500 HV) are significantly harder than steel (250 HV), resisting daily scratches and wear. |

| Density & Corrosion Resistance | A dense, non-porous layer prevents moisture and salt penetration, reducing tarnish and corrosion. |

| Molecular Bond | Forms an atomic bond with the base metal, preventing chipping, flaking, or peeling over time. |

Ready to enhance your product's durability with PVD gold plating? KINTEK specializes in advanced PVD coatings for lab equipment, watches, jewelry, and high-wear fixtures. Our process ensures a finish that lasts for decades, combining superior hardness with lasting aesthetic appeal. Contact our experts today to discuss how PVD can protect and elevate your products!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Touchscreen Automatic Vacuum Heat Press

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

People Also Ask

- What is deposition in environmental chemistry? Understanding How Air Pollution Harms Ecosystems

- How many types of sputtering are there? A Guide to DC, RF, and Advanced Techniques

- How many types of vapor phase deposition techniques are present? PVD vs. CVD Explained

- What are the effects of magnetron sputtering? Achieve High-Quality, Durable Thin Films for Your Lab

- What is a sputtering system? Achieve Unmatched Thin Film Deposition for Your Lab