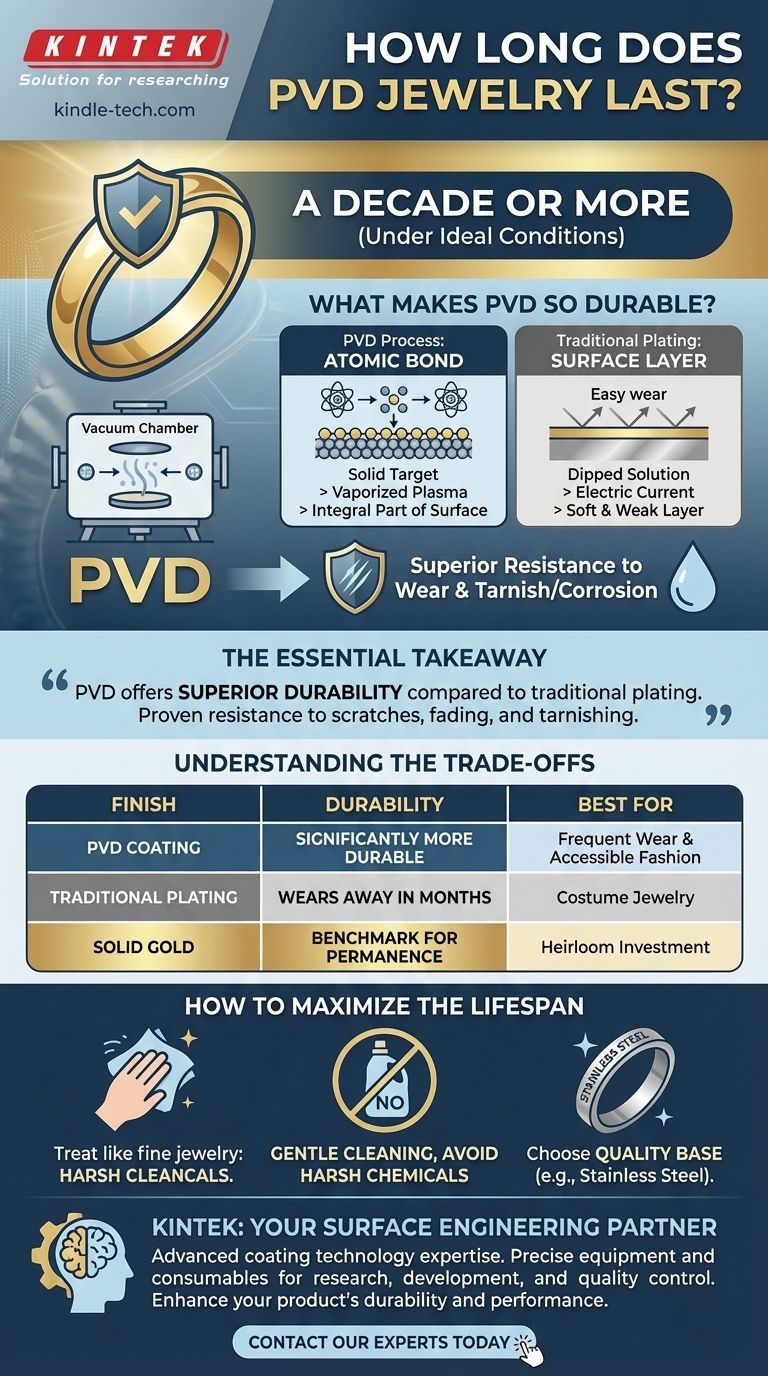

Under ideal conditions, a properly applied Physical Vapor Deposition (PVD) coating on jewelry can last for a decade or more. This remarkable longevity is due to the advanced process used to create it, which forms a durable layer that is significantly more resistant to wear than traditional plating methods. However, the actual lifespan depends heavily on the quality of the application, the base metal used, and how the jewelry is worn and cared for.

The essential takeaway is that PVD offers superior durability compared to any traditional plating. Its value lies not just in a theoretical lifespan, but in its proven resistance to the scratches, fading, and tarnishing that affect most coated jewelry during daily wear.

What Makes PVD So Durable?

The longevity of PVD is not a matter of chance; it's a direct result of the scientific process used to create the coating. It is fundamentally different from simple electroplating.

The PVD Process Explained

PVD, or Physical Vapor Deposition, is a process conducted in a high-tech vacuum chamber. A solid target material (such as titanium nitride, which produces a gold color) is vaporized into a plasma of atoms. These atoms are then bonded molecule by molecule onto the surface of the jewelry, forming a new, hard, and incredibly thin layer.

This creates an atomic bond between the coating and the base metal. Unlike a simple layer of paint or traditional plating that sits on top, the PVD coating becomes an integral part of the surface itself.

Superior Resistance to Wear

The resulting coating is extremely hard and dense. This provides exceptional protection against the scratches, scuffs, and impacts of everyday life. Jewelry with a PVD finish resists abrasion far better than pieces that are merely gold-plated or silver-plated.

A Barrier Against Tarnish and Corrosion

The PVD layer is chemically inert and non-porous. This creates a highly effective barrier that seals the base metal from exposure to air, moisture, sweat, and mild chemicals. As a result, PVD-coated jewelry is highly resistant to the tarnishing and corrosion that can quickly dull other types of jewelry.

Understanding the Trade-offs: PVD vs. Other Finishes

While PVD is highly durable, it's important to understand where it stands in relation to other common jewelry options.

PVD vs. Traditional Gold Plating

Traditional gold plating involves dipping a base metal into a solution containing gold and using an electric current to deposit a very thin layer. This layer is soft and adheres weakly, often wearing away in months with regular use.

PVD is significantly more durable and longer-lasting than traditional plating, making it a far better choice for items you intend to wear frequently.

PVD vs. Solid Gold

Solid gold is the benchmark for permanence, as the entire piece is made of a precious metal alloy. It will not wear off because there is no coating to begin with. While it can scratch, it can also be polished and repaired indefinitely.

PVD jewelry is not an equal substitute for solid gold but serves a different purpose. It offers the appearance and impressive durability of a gold finish at a fraction of the cost, making it an intelligent choice for accessible, long-wearing fashion and daily-use pieces.

How to Maximize the Lifespan of Your PVD Jewelry

Even the most durable coating benefits from proper care. To ensure your PVD jewelry lasts as long as possible, you should treat it like any fine jewelry. Avoid direct contact with harsh chemicals like chlorine, bleach, and perfumes, and clean it gently with a soft cloth.

- If your primary focus is affordable daily wear: Choose PVD-coated jewelry made with a quality base metal like stainless steel for the best combination of durability and price.

- If your primary focus is the best value in coated jewelry: PVD is the undisputed leader, offering a lifespan and resistance to wear that far surpasses any form of traditional plating.

- If your primary focus is an heirloom-quality investment: Opt for solid gold or platinum, as no coating can match the intrinsic permanence of a solid precious metal.

By understanding its unique properties, you can confidently choose PVD jewelry for its exceptional blend of durability, appearance, and value.

Summary Table:

| Factor | Impact on PVD Longevity |

|---|---|

| Coating Quality | Proper application is critical for maximum durability. |

| Base Metal | Higher quality metals (e.g., stainless steel) provide a better foundation. |

| Wear & Care | Avoiding harsh chemicals and abrasion extends lifespan significantly. |

| Comparison to Plating | PVD is far more durable and long-lasting than traditional gold plating. |

Ready to achieve superior, long-lasting finishes for your products?

The advanced coating technology behind durable PVD jewelry is similar to the high-performance solutions we provide for the laboratory. At KINTEK, we specialize in the precise equipment and consumables needed for research, development, and quality control in material science and surface engineering.

Whether you are developing new coating processes or need reliable lab equipment, our expertise can help you enhance your product's durability and performance.

Contact our experts today to discuss how KINTEK's solutions can support your innovation and quality goals.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition