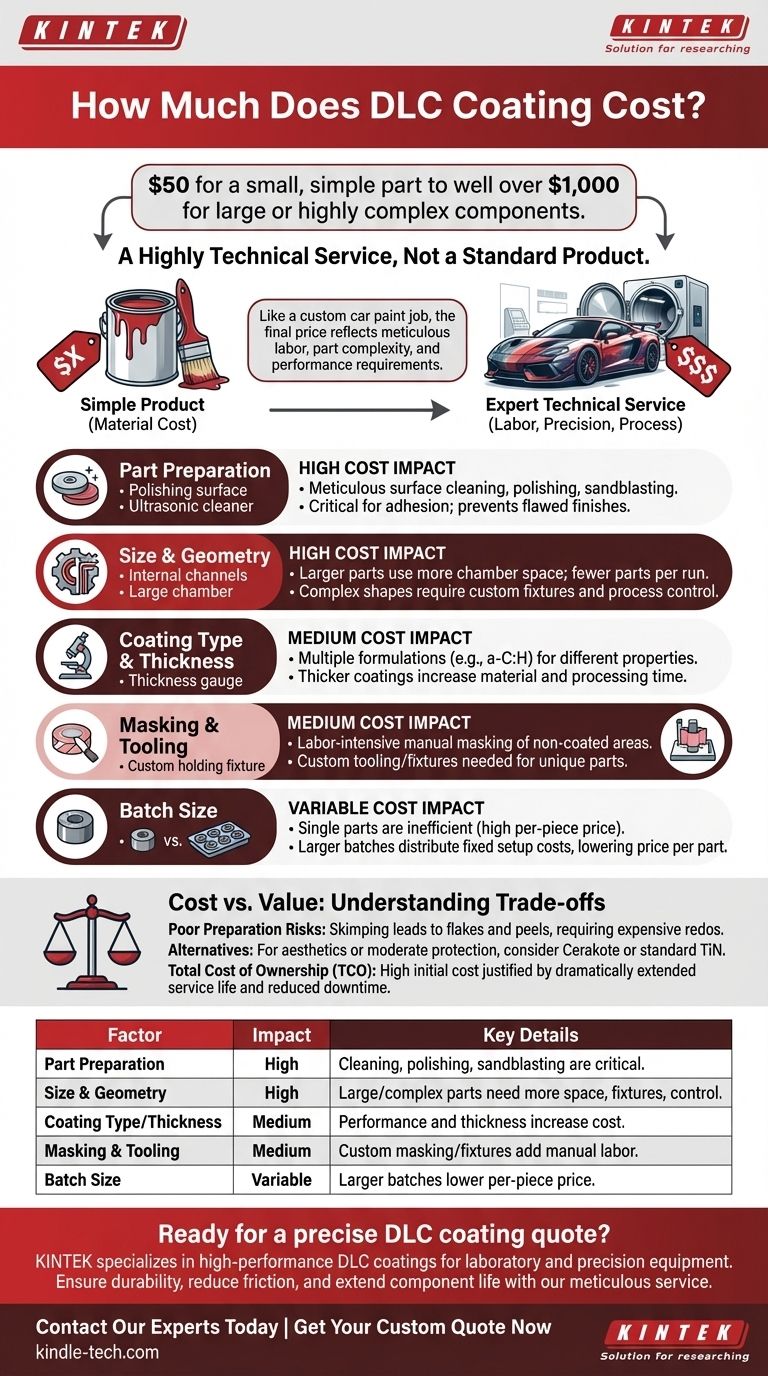

As a direct answer, DLC coating can cost anywhere from $50 for a small, simple part to well over $1,000 for large or highly complex components. This wide range exists because you are not buying a product, but a highly technical service. The final price is a direct reflection of the labor, precision, and specific processes required for your unique item.

The final price of a Diamond-Like Carbon (DLC) coating is not a simple line item. It's a comprehensive cost reflecting the meticulous surface preparation, part complexity, and specific performance requirements of the application.

Why There Is No "Standard" Price for DLC

Thinking about DLC coating is less like buying a can of paint and more like commissioning a custom paint job for a show car. The material cost is a factor, but the dominant expense is the expert labor required to prepare the surface and apply the coating flawlessly.

The process takes place in a vacuum chamber using a technique called Physical Vapor Deposition (PVD). The setup, operation, and time within this chamber are major cost drivers, and these costs must be justified by the parts being coated.

Key Factors That Determine DLC Coating Cost

Understanding what you're being quoted for requires breaking down the service into its core components. The price is built from the ground up based on these five factors.

Part Preparation

This is often the single most significant cost component. The underlying surface must be surgically clean and have the desired texture before it enters the coating chamber.

Any blemish, oil, or microscopic debris on the surface will be permanently trapped under the coating, leading to a flawed finish or outright failure. Common preparation steps include polishing, sandblasting, and ultrasonic cleaning.

Size and Geometry

Larger parts take up more space in the PVD chamber, meaning fewer parts can be coated in a single run. This directly increases the cost per part.

Complex shapes with internal channels, sharp angles, or blind holes are significantly more difficult to coat evenly. They often require custom fixtures and more sophisticated process control, adding to the expense.

Coating Type and Thickness

Not all DLC is the same. There are multiple formulations (such as a-C:H) designed for different levels of hardness, friction, or chemical resistance. A high-performance formulation will cost more.

Similarly, a thicker coating requires more time in the chamber. A typical decorative coating might be 2-5 microns thick, while a high-wear industrial application may require a thicker, more expensive layer.

Masking and Tooling

In many cases, only specific surfaces of a part need to be coated. The other areas must be meticulously covered with custom masking.

This is a labor-intensive manual process. Additionally, each part must be held by a special fixture, or tooling, inside the chamber. For unique parts, this tooling must be custom-made.

Batch Size

There is a significant economy of scale in DLC coating. The cost to set up and run the PVD chamber is largely fixed, whether you are coating one part or one hundred.

Coating a single, one-off part is extremely inefficient and will carry the highest per-piece price. Coating a large batch distributes those setup costs, dramatically lowering the price for each item.

Understanding the Trade-offs: Cost vs. Value

A high price tag doesn't always mean you're getting the best value, and a low price can be a serious red flag.

The High Cost of Poor Preparation

Attempting to save money by skimping on surface preparation is a false economy. It is the most common point of failure for any advanced coating.

A poorly prepared part will result in a coating that flakes, peels, or shows surface flaws, requiring a complete and far more expensive redo.

Is DLC Overkill for Your Application?

DLC offers premier performance, but not every application requires it. Its primary benefits are extreme hardness and low friction.

If your goal is simply color and moderate corrosion resistance, a less expensive coating like Cerakote or a standard Titanium Nitride (TiN) PVD might be a more cost-effective solution.

Longevity and Total Cost of Ownership

A high initial cost for DLC can be easily justified if it dramatically extends the service life of a critical or expensive component.

Consider the cost of replacing the entire part (or the downtime of the machine it belongs to) versus the one-time cost of a coating that prevents wear and failure for years.

Making the Right Choice for Your Application

To determine if the cost is justified, you must align the price with your specific goal.

- If your primary focus is maximum performance and longevity: Focus on a provider who specializes in meticulous surface preparation, as this will dictate the coating's success more than any other factor.

- If your primary focus is aesthetics and moderate wear resistance: A standard DLC application is often sufficient; prioritize clear communication with the applicator about your desired finish (e.g., matte vs. satin).

- If your primary focus is cost-effectiveness on a non-critical part: Objectively evaluate if the benefits of DLC are necessary, or if a less expensive coating could adequately meet your needs.

Ultimately, viewing DLC as a long-term investment in performance and durability is the key to assessing its true cost.

Summary Table:

| Factor | Impact on Cost | Key Details |

|---|---|---|

| Part Preparation | High | Meticulous cleaning, polishing, and sandblasting are critical for coating adhesion and quality. |

| Size & Geometry | High | Large or complex parts require more chamber space, custom fixtures, and complex process control. |

| Coating Type/Thickness | Medium | High-performance formulations and thicker coatings increase material and processing time. |

| Masking & Tooling | Medium | Custom masking and fixtures for unique parts add significant manual labor costs. |

| Batch Size | Variable | Larger batches distribute fixed setup costs, drastically lowering the price per part. |

Ready to get a precise quote for your DLC coating project?

At KINTEK, we specialize in providing high-performance DLC coatings for your laboratory equipment and precision components. Our expertise ensures meticulous surface preparation and application, guaranteeing a coating that enhances durability, reduces friction, and extends the life of your critical parts.

Contact our experts today for a personalized consultation and see how our DLC coating services can provide long-term value for your specific application.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

People Also Ask

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- Is diamond coating worth it? Maximize Component Life and Performance