The energy consumption of a pyrolysis plant is not a single number, but rather a dynamic equation of inputs versus outputs. A plant's net energy balance depends heavily on its design, the type of feedstock it processes, and its operational efficiency. While it requires significant thermal energy to initiate the process, a well-designed plant can often use the energy from its own gaseous byproducts to become partially or even fully self-sustaining.

The core question is not how much energy a pyrolysis plant consumes, but whether it can operate as a net energy producer. The answer is yes, but this outcome is contingent on careful engineering, particularly in feedstock preparation and the internal recycling of energy.

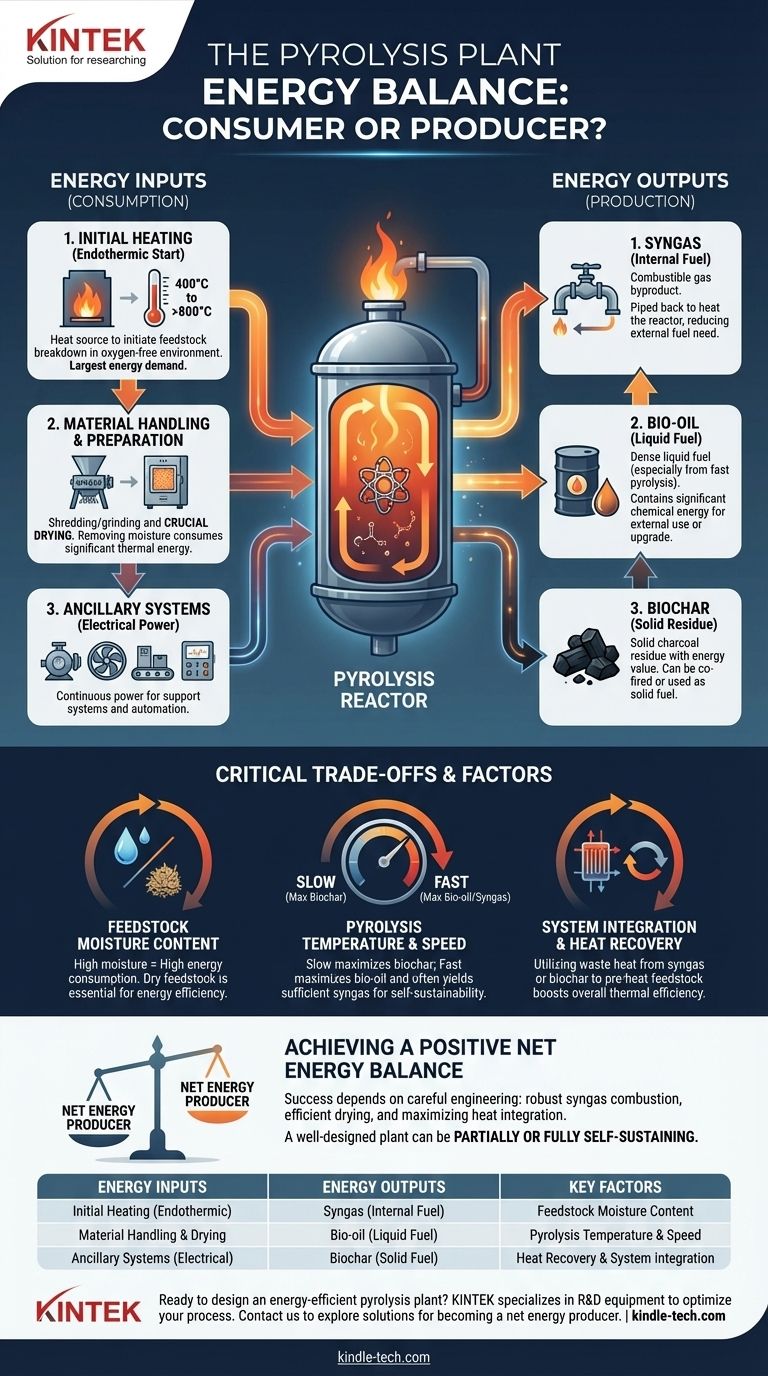

Deconstructing the Energy Inputs

A pyrolysis plant consumes energy in several distinct phases, with the initial heating being the most significant demand. Understanding these inputs is the first step in assessing overall efficiency.

Initial Heating (The Endothermic Start)

Pyrolysis is an endothermic process, meaning it requires an external heat source to begin breaking down the feedstock in an oxygen-free environment. This initial thermal lift is the single largest energy consumer in the entire operation.

The amount of heat required is dictated by the target temperature, which can range from 400°C to over 800°C depending on the desired end products.

Material Handling and Preparation

Raw feedstock is rarely ready for the reactor. It must be prepared, and this preparation consumes significant mechanical and thermal energy.

Key processes include shredding or grinding to increase surface area, and most critically, drying. Removing moisture is paramount, as heating water consumes vast amounts of energy that could otherwise be used for pyrolysis.

Ancillary Systems

Beyond the core reactor, a plant relies on numerous support systems that continuously draw electrical power. These include conveyors for moving feedstock and biochar, pumps for bio-oil, fans and blowers for gas handling, and the control systems that automate the entire process.

Analyzing the Energy Outputs

While a plant consumes energy, it also produces it in three main forms: syngas, bio-oil, and biochar. The key to efficiency is harnessing the energy from these outputs.

Syngas (Non-Condensable Gases)

The pyrolysis process releases a mix of combustible gases known as syngas. This is the plant's most valuable internal energy source.

In most modern plants, this syngas is captured and piped directly back to the burners that heat the pyrolysis reactor. By using its own byproduct as fuel, the plant can dramatically reduce or even eliminate its need for external fuel (like natural gas) after the initial start-up phase.

Bio-oil (Pyrolysis Oil)

Bio-oil is a dense liquid fuel and a primary product of many pyrolysis systems, particularly "fast pyrolysis." This oil represents a significant amount of captured chemical energy.

While it is typically sold as an external product, it is a key part of the plant's positive energy output ledger. It can be used in industrial boilers or upgraded to transportation-grade fuels.

Biochar (Solid Residue)

Biochar, the solid charcoal-like residue, also contains energy. While often sold for agricultural or filtration purposes, it can be co-fired in furnaces or used as a solid fuel, contributing to the overall energy-positive nature of the system.

Understanding the Trade-offs

A plant's status as an energy consumer versus a producer is not guaranteed. It is determined by a series of critical engineering and operational trade-offs.

Feedstock Moisture Content

This is arguably the most critical factor. A feedstock with 50% moisture requires vastly more energy to process than one with 10% moisture. High-moisture inputs can easily turn a potentially energy-positive plant into a net energy sink.

Pyrolysis Temperature and Speed

Slow pyrolysis (lower temperatures, longer processing times) maximizes biochar yield but produces less syngas, potentially providing less internal fuel for the process.

Fast pyrolysis (high temperatures, short processing times) maximizes bio-oil yield and often produces enough syngas to be self-sustaining, but it requires more sophisticated and energy-intensive reactor designs.

System Integration and Heat Recovery

The difference between a mediocre and a great plant is often heat integration. Using heat exchangers to capture waste heat from the syngas or hot biochar to pre-heat incoming feedstock is crucial for maximizing thermal efficiency and minimizing external energy demand.

How to Apply This to Your Project

The viability of a pyrolysis project hinges entirely on achieving a favorable net energy balance. Your design and operational choices should be guided by your primary goal.

- If your primary focus is energy self-sufficiency: Prioritize a feedstock drying system and design for robust syngas combustion to power your main reactor.

- If your primary focus is maximizing liquid fuel (bio-oil): You will likely choose a fast pyrolysis design and must ensure the syngas yield is sufficient to sustain the higher operating temperatures.

- If your primary focus is maximizing biochar production: A simpler, slow pyrolysis design may be adequate, but you must carefully calculate if the lower syngas yield will meet the process's energy needs.

Ultimately, a successful pyrolysis operation should be viewed not as a waste-disposal unit, but as a highly integrated energy-conversion system.

Summary Table:

| Energy Inputs | Energy Outputs | Key Factors |

|---|---|---|

| Initial Heating (Endothermic) | Syngas (Internal Fuel) | Feedstock Moisture Content |

| Material Handling & Drying | Bio-oil (Liquid Fuel) | Pyrolysis Temperature & Speed |

| Ancillary Systems (Electrical) | Biochar (Solid Fuel) | Heat Recovery & System Integration |

Ready to design an energy-efficient pyrolysis plant? KINTEK specializes in lab equipment and consumables for pyrolysis R&D, helping you optimize feedstock preparation, temperature control, and energy recovery. Contact us today to explore how our solutions can turn your pyrolysis project into a net energy producer!

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory Jaw Crusher

- Open Type Two Roll Mixing Mill Machine for Rubber Crusher

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

People Also Ask

- Why is sintering easier in the presence of a liquid phase? Unlock Faster, Lower-Temperature Densification

- How mechanical properties are affected by sintering? Master the Trade-offs for Stronger Materials

- What is a vacuum furnace? The Ultimate Guide to Contamination-Free Thermal Processing

- How does a sputtering machine work? Achieve Atomic-Level Precision for Your Coatings

- What is liquid phase sintering and how is it different from solid state sintering? A Guide to Faster, Denser Materials