The most critical first step in any successful experiment is the proper selection and securing of your sample. You must choose a holder that is appropriate for the sample's specific size, shape, and material, ensuring its placement area can secure the sample so tightly that it becomes completely stable and unable to move during subsequent operations.

The objective is not merely to hold the sample, but to make it an immovable, stable extension of the instrument itself. This transforms the sample from a potential source of error into a controlled, reliable constant.

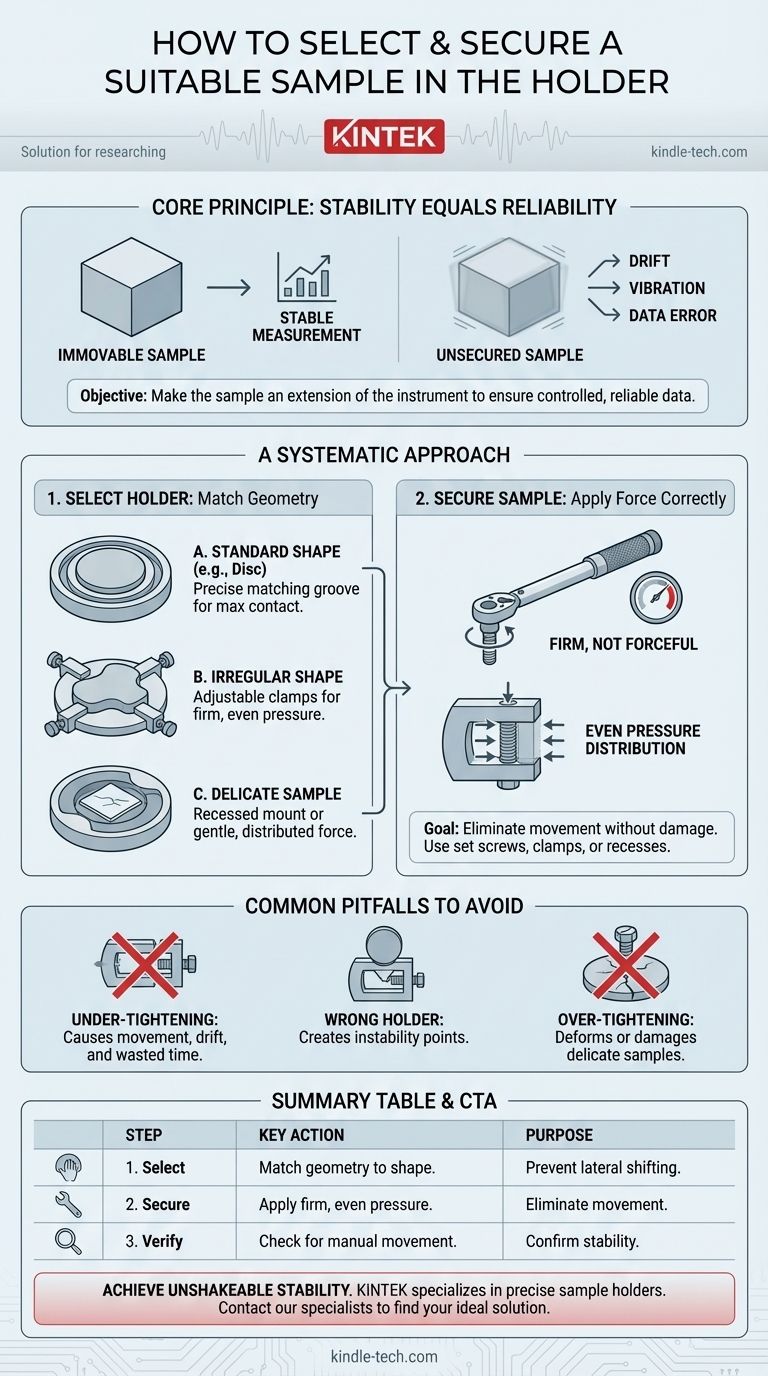

The Core Principle: Stability Equals Reliability

Any successful experiment depends on controlling variables. An improperly secured sample introduces unwanted movement—vibration, shifting, or drift—which can invalidate your results, waste time, and potentially damage sensitive equipment.

Why Every Micrometer of Movement Matters

In high-precision operations, even microscopic shifts can be catastrophic. A sample that seems secure to the naked eye may still move under operational stress, such as the force of a probe, the vibration of a stage, or the impact of an electron beam. This movement directly translates to a loss of focus, inaccurate measurements, and non-repeatable data.

The Holder's True Function

Think of the holder as the interface between your sample and the instrument. Its job is to create a single, rigid system. When secured correctly, any forces applied by the instrument are transferred perfectly to the sample without any loss or deviation due to movement at the junction.

A Systematic Approach to Selection and Securing

A methodical process ensures you address all critical factors, moving from the general shape of the sample to the specifics of how it's held in place.

Match the Holder to the Sample Geometry

The most fundamental step is matching the holder's design to the sample's shape. A poor geometric match is the primary cause of instability.

For example, a circular sample should be placed in a holder with a matching circular groove of the correct inner diameter. This provides 360-degree contact and prevents lateral shifting.

Conversely, an irregularly shaped sample requires a more adaptable solution, such as a holder with adjustable clamps. These can be positioned to apply firm, even pressure at multiple points, accommodating the unique contours of the sample.

Securing the Sample: Applying Force Correctly

Once the right holder is selected, the method of securing it is paramount. The goal is to apply just enough force to eliminate all movement without damaging or deforming the sample.

This is often achieved with set screws, clamps, or a fitted recess. The pressure should be distributed as evenly as possible to avoid creating stress points on the sample.

Common Pitfalls to Avoid

Mistakes in this early stage are common and can have significant consequences. Being aware of them is the first step toward prevention.

The Danger of Under-tightening

This is the most frequent error. A sample that is not secured with sufficient force will inevitably move during the experiment. Always double-check that all fastening mechanisms are fully engaged and that the sample cannot be moved with gentle manual pressure.

The Risk of Over-tightening

The opposite error can be just as damaging. Applying excessive force with clamps or screws can crack, deform, or otherwise destroy a delicate sample. The key is to be firm, not forceful.

Using the Wrong Holder for the Job

It can be tempting to use a readily available holder that is "close enough." This is a false economy. Using a holder that doesn't properly match the sample's geometry creates instability points and makes a secure fit nearly impossible to achieve.

Making the Right Choice for Your Sample

Your specific goal and sample type will determine the best approach. Use these guidelines to make a definitive choice.

- If your sample has a standard geometric shape (e.g., disc, wafer, rectangle): Always prioritize a holder with a precisely machined groove or recess that matches the sample's dimensions perfectly.

- If your sample is irregularly shaped or one-of-a-kind: Use a holder with fully adjustable clamps that allow you to secure the sample at several stable contact points.

- If your sample is delicate or brittle: Select a holder that secures the sample without direct, high-pressure clamping, such as a recessed mount or one that uses a gentle, distributed force.

Ultimately, mastering this foundational step is what separates unreliable data from breakthrough results.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Select Holder | Match holder geometry to sample shape (e.g., groove for a disc). | Creates maximum contact to prevent lateral shifting. |

| 2. Secure Sample | Apply firm, even pressure with clamps or screws. | Eliminates all movement without damaging the sample. |

| 3. Verify Stability | Check that the sample cannot be moved with gentle manual pressure. | Confirms the sample is an immovable extension of the instrument. |

| Common Pitfalls | Avoid under-tightening (causes drift) and over-tightening (damages sample). | Prevents data errors and sample loss. |

Achieve Unshakeable Stability in Your Lab

Proper sample preparation is the foundation of reliable data. Inaccurate results from a poorly secured sample can cost you valuable time and resources. KINTEK specializes in providing the precise lab equipment and consumables you need to master this critical step.

We offer a wide range of high-quality sample holders designed for various geometries and materials, ensuring a perfect match for your specific application. Our experts can help you select the right tool to transform your sample from a variable into a constant.

Stop guessing and start achieving repeatable, breakthrough results. Contact our technical specialists today to discuss your sample preparation challenges and find the ideal solution for your laboratory's needs.

Visual Guide

Related Products

- Customizable XRD Sample Holders for Diverse Research Applications

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Stainless Steel Quick Release Vacuum Chain Three-Section Clamp

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- What are the specific storage requirements for a sample holder? Protect Your Lab's Critical Assets

- What are the limitations of the IR spectroscopy? Understanding Its Boundaries for Accurate Analysis

- How should a sample holder be handled to ensure its longevity? Protect Your Lab Investment and Data Integrity

- What affects melting point chemistry? A Guide to Molecular Forces and Lattice Energy

- What is the minimum sample required for XRD analysis? Optimize Your Material Analysis