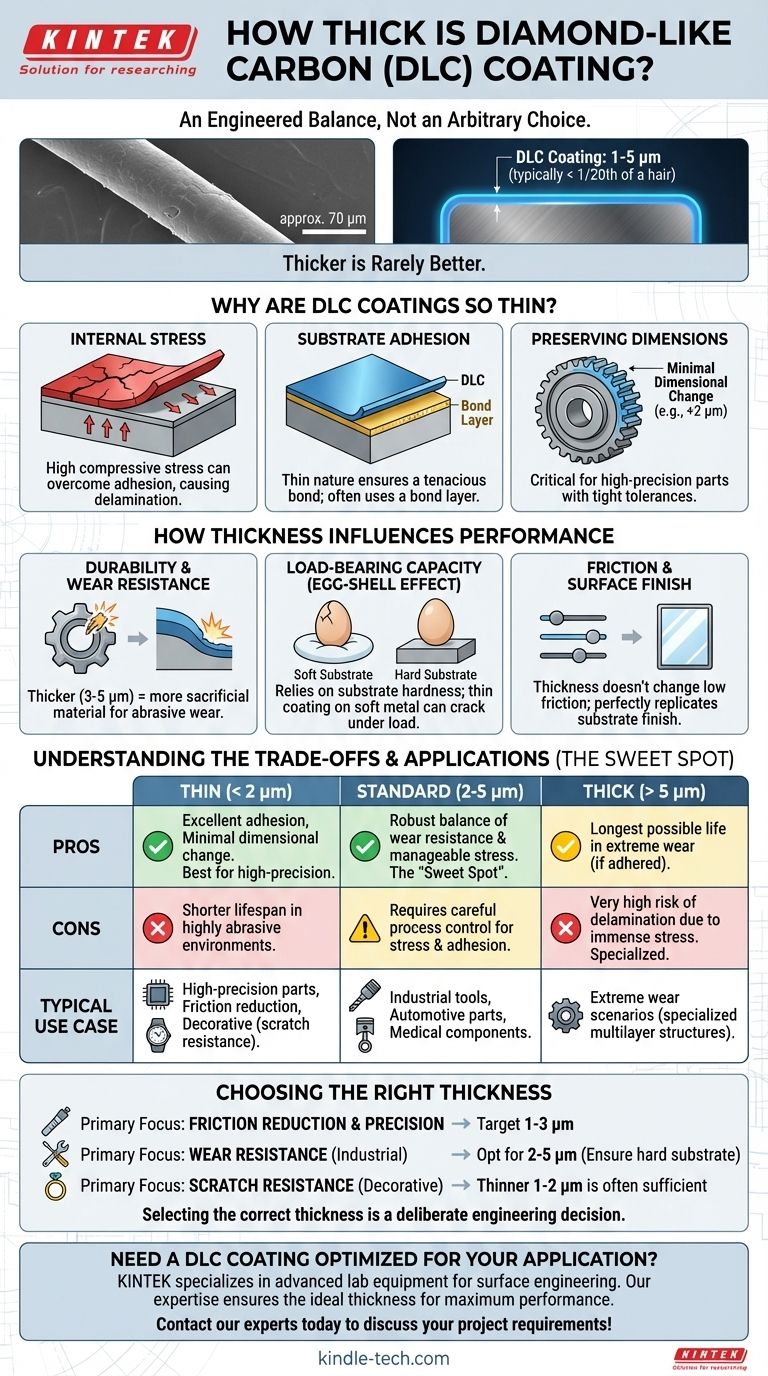

In most engineering applications, a diamond-like carbon (DLC) coating is exceptionally thin, typically ranging from 1 to 5 micrometers (µm). For context, a single micrometer is one-thousandth of a millimeter, meaning a standard DLC coating is often less than one-twentieth the thickness of a human hair. This thickness is not arbitrary but a carefully engineered balance of properties.

The thickness of a DLC coating is a critical trade-off. It must be thick enough to provide durable wear resistance but thin enough to manage internal stress, which, if too high, will cause the coating to flake off the component. "Thicker" is rarely "better."

Why Are DLC Coatings So Thin?

The achievable thickness of a DLC coating is governed by the physics of the deposition process and the material's inherent properties. It is a deliberate choice, not a limitation of capability.

The Primary Limiter: Internal Stress

DLC films are deposited in a high-energy state, which results in high internal compressive stress. Think of it as a tightly stretched skin on the surface of the component.

As the coating gets thicker, this internal stress accumulates. At a certain point, the stress becomes so great that it overcomes the adhesive force bonding the coating to the substrate, causing it to delaminate, crack, or flake off.

The Need for Substrate Adhesion

A coating is only as good as its bond to the material underneath it. The thin nature of DLC helps ensure a tenacious bond.

Managing the interface between the substrate and the first layers of the coating is critical. Often, a very thin, metallic "bond layer" is applied first to act as a glue between the component and the functional DLC layer, improving adhesion and allowing for a slightly thicker, more durable film.

Preserving Component Dimensions

DLC is often applied to high-precision components like engine parts, fuel injectors, and medical implants where tolerances are measured in single microns.

A coating of 2 µm adds 2 µm to the surface. This dimensional change, while small, must be accounted for in the initial design of the part to ensure it fits and functions correctly after coating. A thin coating minimizes this impact.

How Thickness Influences Performance

The chosen thickness directly impacts how the coated part will perform in its intended environment.

Durability and Wear Resistance

For applications facing abrasive wear, such as cutting tools or industrial pistons, a thicker coating (e.g., 3-5 µm) provides more sacrificial material. This extends the service life of the component simply because there is more coating to wear away before the substrate is exposed.

Load-Bearing Capacity

DLC is extremely hard, but it is also very thin. It relies on the hardness of the underlying material (the substrate) to support it under load.

This is known as the "egg-shell effect." If you place a thin, hard eggshell on a soft surface like mud and press on it, the shell will crack because the mud deforms underneath. A hard, thin DLC coating on a soft metal substrate can behave similarly. The thickness must be appropriate for the substrate's hardness and the expected load.

Friction and Surface Finish

The low coefficient of friction is an inherent property of the DLC material itself. While thickness does not change this property, it ensures the low-friction surface remains intact for a longer period.

A thin coating also perfectly replicates the surface finish of the part. If you coat a mirror-polished surface, you will have a mirror-polished DLC surface. If you coat a matte surface, you will have a matte DLC surface.

Understanding the Trade-offs

Choosing a DLC thickness is a balancing act between durability and adhesion.

Thin Coatings (< 2 µm)

- Pros: Exhibit lower internal stress, leading to excellent adhesion. They cause minimal dimensional change, making them ideal for high-precision components with tight tolerances.

- Cons: Offer a shorter lifespan in highly abrasive or erosive environments due to the limited amount of sacrificial material.

Standard Coatings (2-5 µm)

- Pros: This is the "sweet spot" for most applications, offering a robust balance of excellent wear resistance and manageable internal stress. It is the most common range for industrial, automotive, and medical components.

- Cons: Requires careful process control to manage stress and ensure adhesion. The dimensional change must be factored into the part's design.

Thick Coatings (> 5 µm)

- Pros: Can provide the longest possible life in extreme wear scenarios, provided the coating can remain adhered to the part.

- Cons: Carry a very high risk of delamination due to immense internal stress. These are reserved for very specific applications and often require specialized multilayer structures to be successful.

Choosing the Right Thickness for Your Application

The optimal thickness is defined entirely by the problem you are trying to solve.

- If your primary focus is friction reduction for high-precision parts: Target the 1-3 µm range to get excellent durability with minimal impact on critical component tolerances.

- If your primary focus is wear resistance for industrial tools or components: Opt for a coating in the 2-5 µm range, ensuring the substrate material is sufficiently hard to support the coating under load.

- If your primary focus is scratch resistance for decorative items: A thinner coating of 1-2 µm is often sufficient, providing superior surface hardness without significant cost or risk.

Ultimately, selecting the correct DLC thickness is a deliberate engineering decision, not a matter of simply choosing the thickest option available.

Summary Table:

| Coating Thickness | Typical Use Case | Key Characteristics |

|---|---|---|

| < 2 µm | High-precision parts, friction reduction | Excellent adhesion, minimal dimensional change |

| 2-5 µm (Standard) | Industrial tools, automotive parts | Optimal balance of wear resistance and stress |

| > 5 µm | Extreme wear scenarios (specialized) | High risk of delamination, requires careful engineering |

Need a DLC coating optimized for your specific application? KINTEK specializes in advanced lab equipment and consumables for surface engineering. Our expertise ensures your components receive the ideal coating thickness for maximum durability and performance. Contact our experts today to discuss your project requirements!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Isostatic Molding Pressing Molds for Lab

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What advantages do rotating bed reactors offer compared to fixed-bed reactors? Unlock Precise Material Performance

- What is vapor deposition of graphene? A Guide to Scalable, High-Quality Production

- Are the important thin film deposition methods? PVD vs. CVD Explained for Your Application

- What is the sputtering method? A Guide to Precision Thin Film Deposition

- Is chemical Vapour deposition bottom-up approach? Build Materials Atom by Atom

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- How is an ultrasonic bath utilized during the diamond seeding phase of substrate preparation? Enhance CVD Nucleation

- Why are induction coils in induction heating CVD systems typically made of copper tubes and cooled with water?