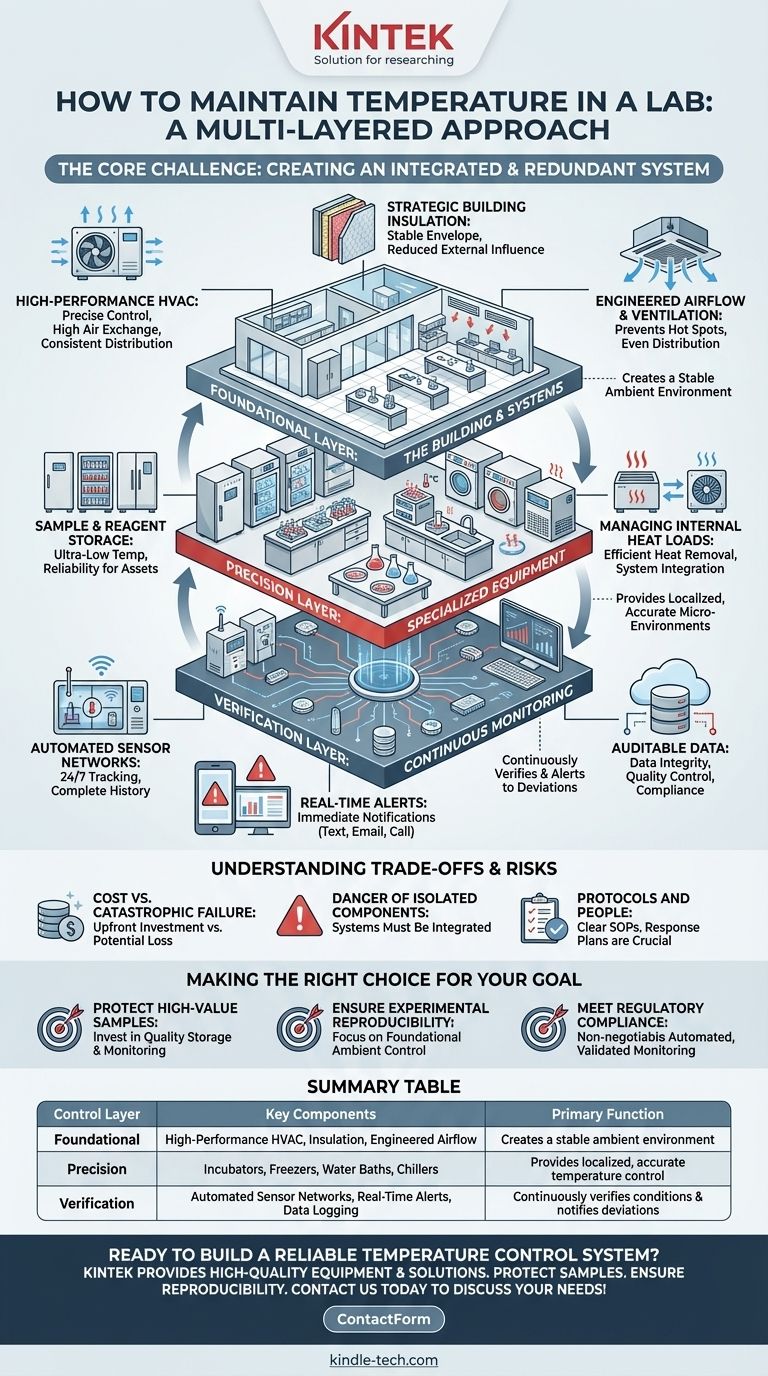

To maintain temperature in a lab, you must implement a multi-layered system. This involves using a precise HVAC system for ambient control, high-quality building insulation to create a stable envelope, specialized equipment like incubators and freezers for localized control, and a continuous, automated monitoring system to verify conditions and alert you to deviations.

The core challenge of laboratory temperature control is not about managing a single variable, but about creating an integrated and redundant system. True stability comes from layering broad environmental controls with precision equipment, all validated by a vigilant, automated monitoring network.

The Foundational Layer: The Building and Its Systems

The first layer of control is the laboratory space itself. Getting the macro-environment right reduces the burden on all subsequent systems and is the bedrock of temperature stability.

High-Performance HVAC

Standard office heating, ventilation, and air conditioning (HVAC) systems are inadequate for a laboratory. A lab requires a system engineered for precise control, higher air exchange rates, and consistent temperature distribution across different zones.

Strategic Building Insulation

The building's "envelope"—its walls, windows, ceiling, and flooring—plays a critical role. Proper insulation minimizes the influence of external weather conditions, creating a more stable internal baseline and reducing the energy load on your HVAC system.

Engineered Airflow and Ventilation

Ventilation is about more than just air quality; it is a key tool for temperature management. Proper airflow engineering prevents the formation of "hot spots" around heat-generating equipment and ensures the conditioned air is distributed evenly throughout the space.

The Precision Layer: Specialized Equipment

While the room's HVAC system sets the ambient temperature, most sensitive materials and processes require their own tightly controlled micro-environments.

Sample and Reagent Storage

This is the most common form of precision control. Refrigerators, freezers, and cryogenic storage units are designed to maintain specific temperatures far different from the room's ambient condition. Their reliability is paramount for protecting high-value assets.

Direct Experimental Control

Equipment like incubators, water baths, and chillers provides direct temperature control for active experiments. They allow you to manipulate conditions with a high degree of accuracy for specific protocols.

Managing Internal Heat Loads

A critical and often overlooked factor is the heat generated by lab equipment itself. Centrifuges, computers, and even freezers exhaust heat into the room. Your foundational HVAC system must be sized and configured to effectively remove this continuous heat load.

The Verification Layer: Continuous Monitoring

Without accurate, continuous data, you cannot be certain your control systems are working. A monitoring system is your insurance policy against silent failures.

The Limits of Manual Checks

Relying on staff to manually log temperatures once or twice a day is inherently risky. A critical fluctuation can easily occur between these checks, compromising weeks of work or entire sample inventories without anyone knowing until it's too late.

Automated Monitoring Systems

A modern laboratory temperature monitoring system uses a network of sensors to track conditions 24/7. These sensors feed data to a central system that logs every reading, providing a complete and unbroken history of the environment.

Real-Time Alerts and Auditable Data

The two primary benefits of an automated system are immediate alerts and data integrity. If a freezer door is left ajar or an incubator begins to fail, the system will instantly send a notification via text, email, or call, allowing for rapid intervention. The continuous data log is also essential for quality control and meeting regulatory compliance requirements.

Understanding the Trade-offs and Risks

Implementing a robust system requires careful planning and investment. Understanding the trade-offs is key to making sound decisions.

Cost vs. Catastrophic Failure

The upfront investment in a high-performance HVAC system and a comprehensive monitoring network can seem high. However, this cost must be weighed against the potential financial and scientific loss from a single failed experiment, a compromised batch of samples, or a regulatory non-compliance finding.

The Danger of Isolated Components

Simply buying the best freezer or the most expensive HVAC unit is not a solution. If these systems are not designed to work together, they can fail. For example, placing too many heat-generating freezers in a poorly ventilated room will overwhelm the air conditioning, putting all the equipment at risk.

Protocols and People

Technology alone is insufficient. Your team must have clear, documented Standard Operating Procedures (SOPs) for routine maintenance, calibration, and, most importantly, how to respond to an automated alert. An alert that goes ignored is useless.

Making the Right Choice for Your Goal

Your strategy should be tailored to your lab's specific priorities.

- If your primary focus is protecting high-value samples: Invest first in high-quality, purpose-built storage units (freezers, incubators) connected to an automated monitoring system with real-time alerts.

- If your primary focus is ensuring experimental reproducibility: Concentrate on the foundational layer by stabilizing ambient room temperature with a zoned, high-performance HVAC system and engineered airflow.

- If your primary focus is meeting regulatory compliance: The non-negotiable core of your strategy must be a validated, automated temperature monitoring system that provides a complete, auditable data log.

By deliberately layering foundational controls with precision equipment and vigilant monitoring, you build a laboratory environment that actively protects the integrity of your work.

Summary Table:

| Control Layer | Key Components | Primary Function |

|---|---|---|

| Foundational (Building) | High-Performance HVAC, Building Insulation, Engineered Airflow | Creates a stable ambient environment for the entire lab space. |

| Precision (Equipment) | Incubators, Freezers, Water Baths, Chillers | Provides localized, accurate temperature control for samples and experiments. |

| Verification (Monitoring) | Automated Sensor Networks, Real-Time Alerts, Data Logging | Continuously verifies conditions and provides immediate notification of deviations. |

Ready to build a reliable temperature control system for your lab?

At KINTEK, we specialize in providing the high-quality lab equipment and consumables you need to create a stable environment. From precision incubators and freezers to robust monitoring solutions, our products are designed to protect your valuable samples and ensure experimental reproducibility.

Let our experts help you design a system tailored to your specific goals. Contact us today to discuss your laboratory's needs!

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Scientific Electric Heating Blast Drying Oven

- Automatic Laboratory Heat Press Machine

- Variable Speed Peristaltic Pump

People Also Ask

- What are the main advantages of Chemical Vapor Deposition (CVD)? Achieve Precision Coating for Complex Geometries

- What role does Chemical Vapor Deposition (CVD) equipment play in the preparation of C/C composites? Expert Analysis

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit