Fundamentally, the industrial importance of carbon nanotubes (CNTs) stems from their extraordinary ability to enhance material properties at a microscopic level. Their unique combination of electrical conductivity, mechanical strength, and high aspect ratio makes them a powerful additive. Currently, their most significant impact is as a high-performance conductive additive in lithium-ion battery cathodes, directly enabling the advancement of electric vehicles and other green technologies.

While their potential applications are vast, the present-day industrial significance of carbon nanotubes is overwhelmingly driven by their proven ability to improve the performance of lithium-ion batteries—a technology cornerstone for global electrification and decarbonization.

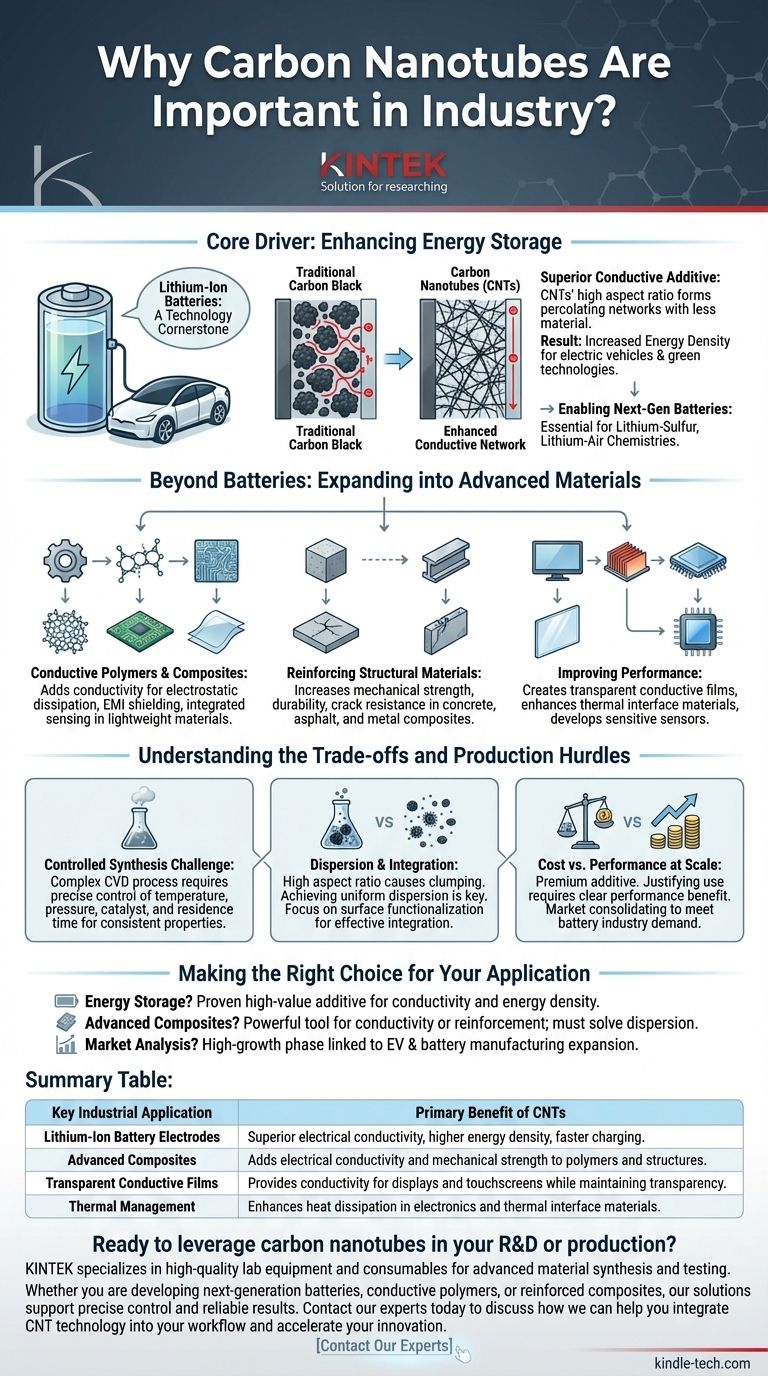

The Core Driver: Enhancing Energy Storage

The most immediate and large-scale industrial use for CNTs is in energy storage, specifically within lithium-ion batteries. This application leverages their exceptional electrical properties.

Why Conductivity Matters in a Battery

A battery's performance, including its power output and charging speed, is limited by how quickly electrons can move within its electrodes. The active materials in a cathode often have poor intrinsic electrical conductivity.

To overcome this, conductive additives are mixed into a paste to create a network for electrons to travel. The better this network, the more efficiently the battery operates.

The Role of CNTs as a Conductive Additive

Carbon nanotubes serve as a superior conductive additive compared to traditional materials like carbon black. Their very high aspect ratio (extremely long and thin) allows them to form a robust, percolating conductive network using significantly less material.

This efficiency means more space in the cathode can be dedicated to the active, energy-storing material, directly increasing the battery's energy density. This is crucial for applications like electric vehicles, where range is a primary concern.

Enabling Next-Generation Battery Chemistries

Beyond current lithium-ion technology, CNTs are a critical component in the research and development of next-generation batteries. Their properties are essential for stabilizing new chemistries like lithium-sulfur and lithium-air, which promise even greater energy densities.

Beyond Batteries: Expanding into Advanced Materials

While batteries are the lead application, the unique properties of CNTs are making them increasingly important in the world of advanced composites and materials.

Creating Conductive Polymers and Composites

CNTs can be integrated into plastics and fiber-reinforced polymers to make them electrically conductive. This is valuable for applications requiring electrostatic dissipation, EMI shielding, or integrated sensing capabilities in lightweight structures.

Reinforcing Structural Materials

The remarkable mechanical strength of CNTs makes them a target for reinforcing materials like concrete, asphalt, and even metal composites. Adding even small amounts can potentially increase durability, crack resistance, and overall lifespan.

Improving Performance in Other Areas

Innovation is driving CNTs into diverse fields. They are being used to create transparent conductive films for displays, enhance thermal interface materials for cooling electronics, and develop highly sensitive chemical and biological sensors.

Understanding the Trade-offs and Production Hurdles

The immense potential of CNTs is balanced by significant technical challenges in their production and implementation. Understanding these is key to appreciating their true industrial context.

The Challenge of Controlled Synthesis

Producing high-quality CNTs with consistent properties is a complex chemical process, typically involving Chemical Vapor Deposition (CVD). Factors like temperature, pressure, and catalyst type must be precisely controlled.

Maintaining an optimal "residence time"—the duration the carbon source is in the reactor—is critical. Too little time wastes materials, while too much can create unwanted by-products and limit growth, making large-scale, high-quality production a sophisticated engineering feat.

Dispersion and Integration

Because of their high aspect ratio and strong intermolecular forces, carbon nanotubes have a natural tendency to clump together. Achieving a uniform dispersion within a host material (like a polymer or battery paste) is a major challenge.

Poor dispersion negates the benefits of their properties. Much of the innovation in the field focuses on "functionalization"—modifying the surface of CNTs to help them integrate more effectively.

Cost vs. Performance at Scale

While the cost of CNTs has decreased as production volumes increase, they remain a premium additive. Justifying their use requires a clear performance benefit that cannot be achieved with cheaper, traditional alternatives. The market is currently consolidating as major players expand to meet the growing demand from the battery industry.

Making the Right Choice for Your Application

To leverage CNTs effectively, you must align their specific benefits with your primary goal.

- If your primary focus is energy storage: CNTs are a proven, high-value additive for improving the conductivity and energy density of lithium-ion battery electrodes.

- If your primary focus is advanced composites: CNTs are a powerful tool for adding electrical conductivity or mechanical reinforcement, but success depends on solving the dispersion and integration challenge.

- If your primary focus is supply chain or market analysis: The CNT market is in a high-growth phase, tightly linked to the expansion of the electric vehicle and battery manufacturing sectors.

Ultimately, harnessing the power of carbon nanotubes requires focusing on how their specific, exceptional properties can solve a targeted industrial problem.

Summary Table:

| Key Industrial Application | Primary Benefit of CNTs |

|---|---|

| Lithium-Ion Battery Electrodes | Superior electrical conductivity, enabling higher energy density and faster charging |

| Advanced Composites | Adds electrical conductivity and mechanical strength to polymers and structural materials |

| Transparent Conductive Films | Provides conductivity for displays and touchscreens while maintaining transparency |

| Thermal Management | Enhances heat dissipation in electronics and thermal interface materials |

Ready to leverage carbon nanotubes in your R&D or production? KINTEK specializes in high-quality lab equipment and consumables for advanced material synthesis and testing. Whether you are developing next-generation batteries, conductive polymers, or reinforced composites, our solutions support precise control and reliable results. Contact our experts today to discuss how we can help you integrate CNT technology into your workflow and accelerate your innovation.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is coating thickness important? Achieve Optimal Performance and Cost Control

- What are the examples of thin film materials? Metals, Dielectrics & Semiconductors for Your Application

- What is the target sputtering deposition? A Guide to Precision Thin-Film Coating

- Which parameters affect sputter yield using an ion beam? Master Ion Energy, Mass, Angle & Material Properties

- What are the sources of graphene? From Graphite to High-Performance Applications

- What is thin film deposition metals? Enhance Your Substrate with Advanced Metal Coatings

- What are the synthesis and purification methods for carbon nano tubes? Scaling Quality and Purity for Your Application

- What is the sputtering process of magnetron co? A Guide to Advanced Thin-Film Deposition