To produce carbon nanotubes, the industry overwhelmingly relies on a process called Chemical Vapor Deposition (CVD) due to its scalability and control. While older methods like arc discharge and laser ablation exist, they are not suitable for large-scale commercial production. Emerging techniques now focus on using more sustainable feedstocks like captured carbon dioxide and methane.

The core challenge in carbon nanotube production has been scaling from lab-grade synthesis to industrial volume. While historical methods produce high-quality material, only Chemical Vapor Deposition (CVD) has proven capable of delivering the cost-effectiveness and volume required for major commercial applications like batteries and composites.

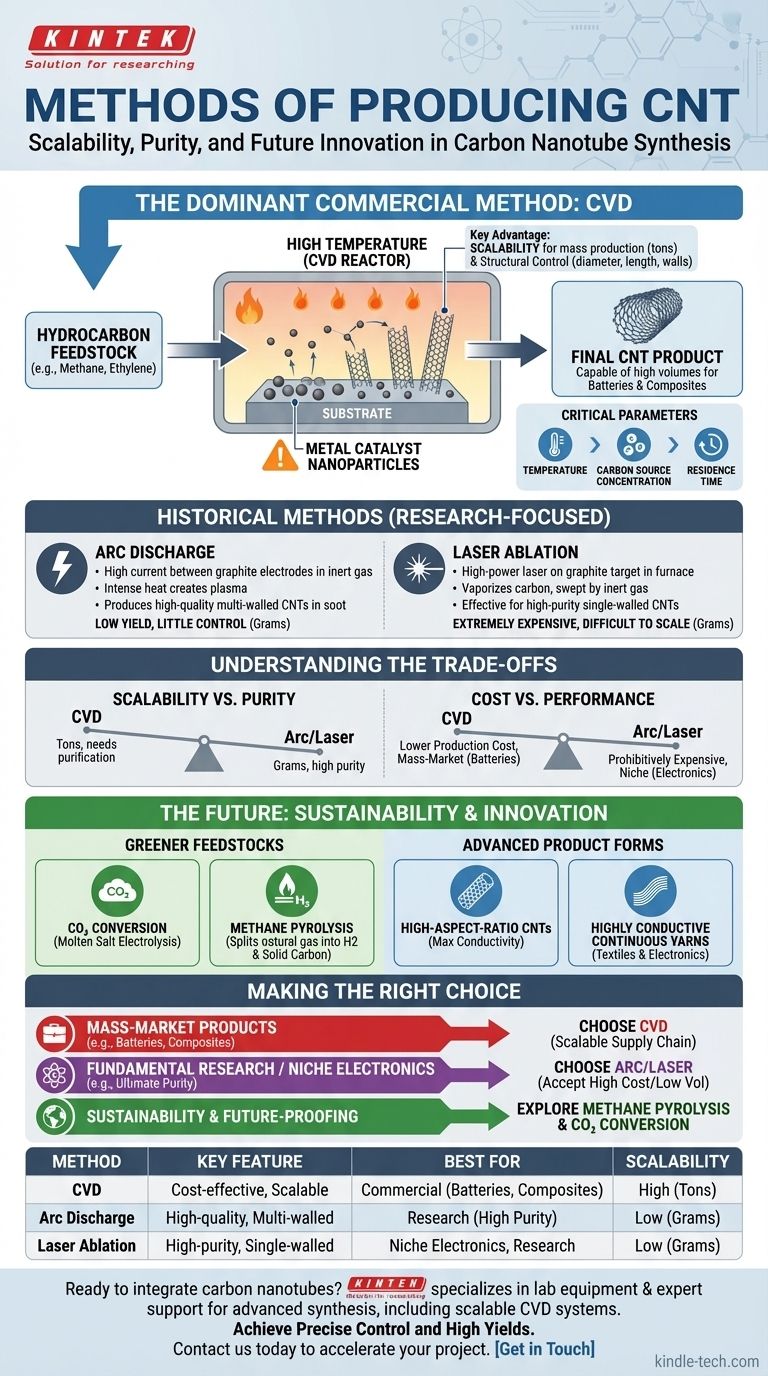

The Dominant Commercial Method: Chemical Vapor Deposition (CVD)

Chemical Vapor Deposition is the workhorse of the CNT industry. It is a highly versatile and scalable process that has enabled the widespread adoption of carbon nanotubes in various fields.

How CVD Works

The CVD process involves flowing a carbon-containing gas (a hydrocarbon feedstock like methane or ethylene) over a substrate coated with metal catalyst nanoparticles at high temperatures. The hydrocarbon decomposes at the catalyst surface, and the carbon atoms assemble into the tube-like structure of CNTs.

Why CVD Dominates

The primary advantage of CVD is its scalability. It can be adapted for continuous or large-batch production, making it the only economically viable method for the volumes needed in applications like lithium-ion batteries. It also offers a significant degree of control over the final CNT structure, such as diameter, length, and wall number.

Critical Parameters for Success

To ensure high yield and consistent quality, operators must precisely control several factors. The most critical parameters are the reaction temperature, the concentration of the carbon source, and the residence time of the gas in the reactor. Fine-tuning these variables directly influences the productivity and efficiency of the synthesis.

Historical Production Methods

Before CVD became dominant, two main high-energy methods were used for producing CNTs. These are now largely confined to research settings due to their limitations in scale and cost.

Arc Discharge

In this method, a very high electrical current is passed between two graphite electrodes in an inert gas atmosphere. The intense heat creates a plasma that vaporizes the carbon, which then condenses to form CNTs in the resulting soot. While it can produce high-quality nanotubes, the process has low yield and offers little control.

Laser Ablation

Here, a high-power laser is aimed at a graphite target inside a high-temperature furnace. The laser vaporizes the carbon, which is then swept away by an inert gas, allowing nanotubes to grow. This method is effective for producing high-purity single-walled carbon nanotubes (SWCNTs) but is extremely expensive and difficult to scale.

Understanding the Trade-offs

The choice of production method is a direct trade-off between the quality of the CNTs and the economics of producing them.

Scalability vs. Purity

CVD excels at scalability, producing tons of material, but the resulting product may contain amorphous carbon or catalyst residues that require purification. In contrast, arc discharge and laser ablation can yield higher-purity CNTs directly, but their output is measured in grams, not tons, making them unsuitable for industrial use.

Cost vs. Performance

The high energy input and low yield of arc discharge and laser ablation make them prohibitively expensive for most applications. CVD's relatively lower production cost is the primary reason CNTs can be used as conductive additives in mass-market products like electric vehicle batteries and advanced polymers.

The Future of CNT Production: Sustainability and Innovation

The next frontier for CNT production is not just about making more, but making it better and greener. Innovation is focused on both the feedstock and the final product form.

Greener Feedstocks

Significant research is underway to move away from traditional hydrocarbon feedstocks. Emerging methods include using captured carbon dioxide (CO2), which is converted into carbon through molten salt electrolysis, and methane pyrolysis, which splits natural gas into hydrogen gas and solid carbon (CNTs), offering a low-emissions pathway.

Advanced Product Forms

Innovation also extends beyond the raw CNT powder. Companies are developing value-added products like high-aspect-ratio nanotubes for maximum conductivity, creating hybrid materials by blending CNTs with other additives, and forming highly conductive continuous yarns for use in advanced textiles and electronics.

Making the Right Choice for Your Goal

The optimal production method is entirely dependent on your end-use application and strategic goals.

- If your primary focus is mass-market commercial products (batteries, composites, tires): Your supply chain must be based on suppliers using a scalable Chemical Vapor Deposition (CVD) process.

- If your primary focus is fundamental research or niche electronics requiring ultimate purity: Materials produced via arc discharge or laser ablation may be suitable, provided the high cost and low volume are acceptable.

- If your primary focus is on sustainability and future-proofing your technology: Keep a close watch on emerging methods like methane pyrolysis and CO2 conversion, as they represent the future of cost-effective and environmentally friendly production.

Understanding the production landscape is the first step to effectively leveraging the unique properties of carbon nanotubes in your application.

Summary Table:

| Method | Key Feature | Best For | Scalability |

|---|---|---|---|

| Chemical Vapor Deposition (CVD) | Cost-effective, scalable process | Commercial applications (batteries, composites) | High (tons) |

| Arc Discharge | High-quality, multi-walled CNTs | Research requiring high purity | Low (grams) |

| Laser Ablation | High-purity single-walled CNTs | Niche electronics, fundamental research | Low (grams) |

Ready to integrate carbon nanotubes into your application?

Choosing the right production method is critical for performance and cost. KINTEK specializes in providing the lab equipment and expert support needed for advanced material synthesis, including CVD systems for scalable CNT production.

We help our customers in R&D and industrial labs achieve precise control and high yields. Contact us today to discuss how our solutions can accelerate your project: Get in Touch

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance