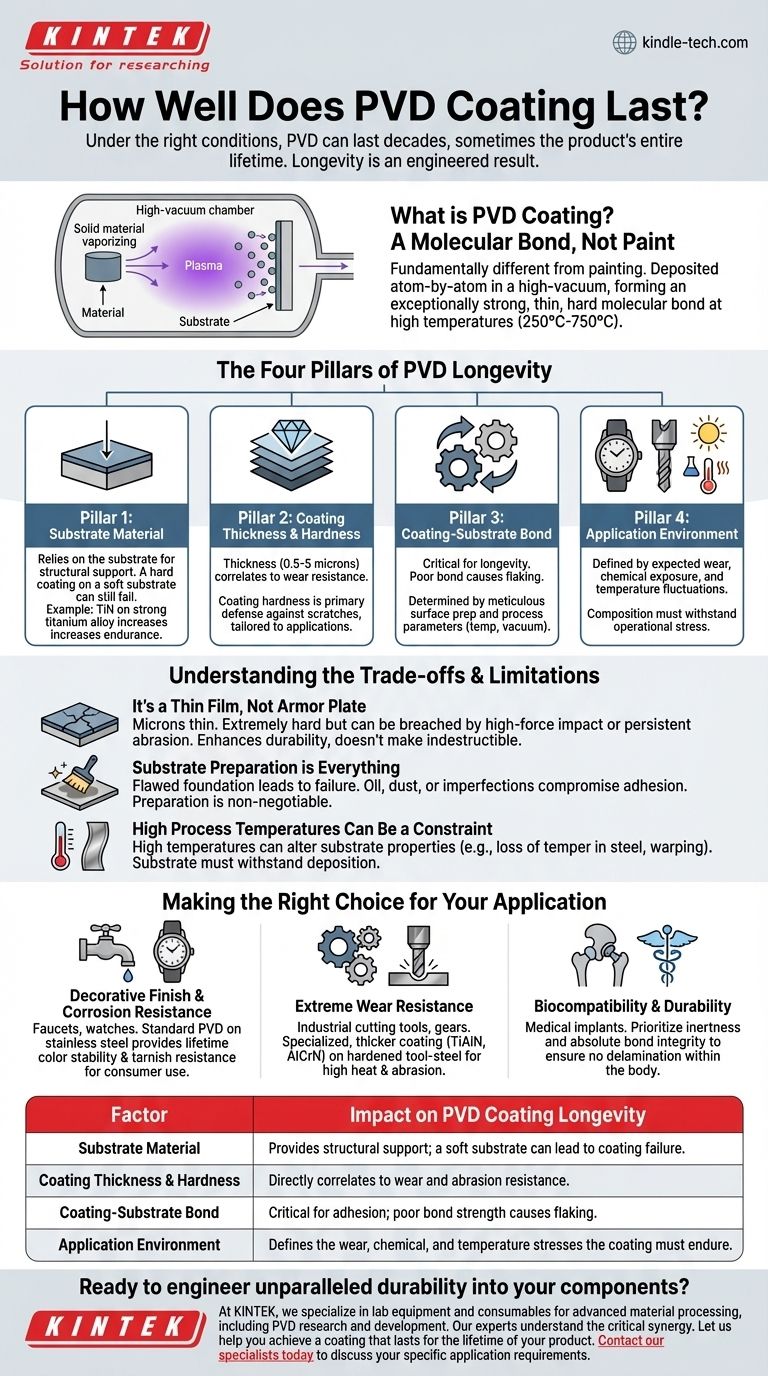

Under the right conditions, a PVD coating can last for decades, sometimes even for the entire lifetime of the product. The lifespan is not a single number but a direct result of the specific coating material, its thickness, the substrate it is applied to, and the environmental stress it endures. It is a highly durable finish, but its longevity is a function of its engineering.

The question is not simply "how long does PVD last," but rather "what factors must be controlled to make PVD last for my specific application?" Its durability is not inherent in the name alone; it is engineered through a careful synergy of material science and process control.

What is PVD Coating? A Molecular Bond, Not Paint

Physical Vapor Deposition (PVD) is fundamentally different from traditional plating or painting. It is not a layer of liquid that dries on a surface.

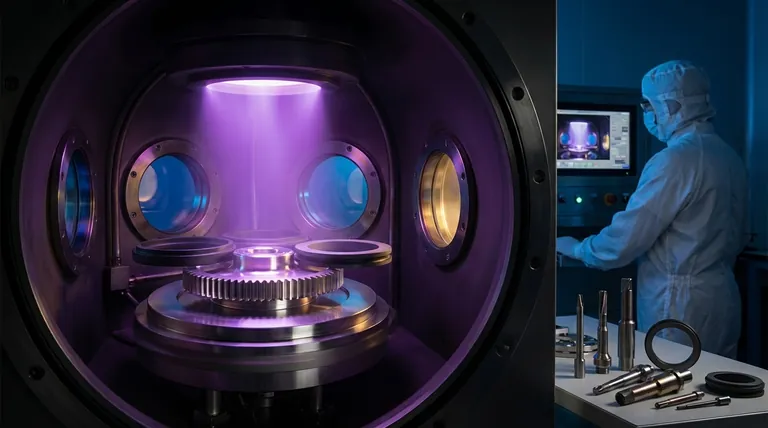

The Deposition Process

The process takes place in a high-vacuum chamber. A solid material, such as Titanium Nitride, is vaporized into a plasma.

This plasma is then deposited, atom by atom, onto the component (the "substrate"). This creates a very thin, hard, and tightly bonded film on the surface.

A Molecular-Level Change

Because this happens at a molecular level and often at high temperatures (250°C to 750°C), the coating forms an exceptionally strong bond with the substrate. This is why PVD coatings are known for their superior resistance to wear and corrosion compared to other methods.

The Four Pillars of PVD Longevity

The durability of a PVD coating is not accidental. It is determined by four interconnected factors. Understanding these is key to specifying a coating that will meet your expectations.

Pillar 1: The Substrate Material

The PVD coating's performance is inseparable from the material it is on. The coating is a thin film, typically between 0.5 and 5 microns, and relies on the substrate for its structural support.

A hard coating on a soft substrate will still dent easily, potentially cracking the coating. The base material dictates the final product's overall strength and fatigue resistance.

For example, a Titanium Nitride (TiN) coating on a strong titanium alloy can significantly increase the component's endurance and fatigue limit.

Pillar 2: Coating Thickness and Hardness

Thickness directly correlates to wear resistance. A thicker coating will take longer to wear through under abrasive conditions.

However, the hardness of the coating material itself is the primary defense against scratches and wear. Different PVD materials offer different levels of hardness, tailored to specific applications.

Pillar 3: The Coating-Substrate Bond

The strongest, hardest coating is useless if it flakes off. The bond strength between the coating and the substrate is arguably the most critical factor for longevity.

This bond is determined by meticulous surface preparation and the specific PVD process parameters, including temperature and vacuum pressure. A poor bond is the most common cause of premature PVD failure.

Pillar 4: The Application Environment

A PVD-coated watch case exposed to occasional friction will last much longer than a PVD-coated industrial cutting tool subjected to extreme heat and abrasion every day.

You must define the expected wear, chemical exposure, and temperature fluctuations. The coating's composition and thickness must be chosen to withstand its specific operational environment.

Understanding the Trade-offs and Limitations

While incredibly effective, PVD is not an invincible solution. Objectivity requires acknowledging its limitations.

It's a Thin Film, Not Armor Plate

A PVD coating is microns thin. While extremely hard and dense, it can be breached by a sharp, high-force impact or worn away by extreme, persistent abrasion. It enhances durability; it does not make a part indestructible.

Substrate Preparation is Everything

The PVD process cannot fix a flawed foundation. Any oil, dust, or imperfections on the substrate's surface will compromise the coating's adhesion, leading to blistering or flaking. The cost and time of proper surface preparation are non-negotiable.

High Process Temperatures Can Be a Constraint

The high temperatures required for many PVD processes can alter the properties of the substrate material. For example, some heat-treated steels may lose their temper, or certain alloys may warp. The substrate must be able to withstand the deposition environment.

Making the Right Choice for Your Application

To get the performance you need, you must match the PVD specification to your primary goal.

- If your primary focus is decorative finish and corrosion resistance (e.g., faucets, watches): A standard PVD coating on stainless steel will provide a lifetime of color stability and tarnish resistance for typical consumer use.

- If your primary focus is extreme wear resistance (e.g., industrial cutting tools, gears): You need a specialized, thicker coating (like TiAlN or AlCrN) applied to a hardened tool-steel substrate to handle high temperatures and abrasion.

- If your primary focus is biocompatibility and durability (e.g., medical implants): The coating and substrate choice must prioritize inertness and absolute bond integrity to ensure no material delaminates within the body.

By understanding these controlling factors, you can effectively engineer the longevity of your product.

Summary Table:

| Factor | Impact on PVD Coating Longevity |

|---|---|

| Substrate Material | Provides structural support; a soft substrate can lead to coating failure. |

| Coating Thickness & Hardness | Directly correlates to wear and abrasion resistance. |

| Coating-Substrate Bond | Critical for adhesion; poor bond strength causes flaking. |

| Application Environment | Defines the wear, chemical, and temperature stresses the coating must endure. |

Ready to engineer unparalleled durability into your components? The longevity of a PVD coating is a precise science. At KINTEK, we specialize in lab equipment and consumables for advanced material processing, including PVD research and development. Our experts understand the critical synergy between substrate, coating material, and process parameters. Let us help you achieve a coating that lasts for the lifetime of your product. Contact our specialists today to discuss your specific application requirements and discover the right PVD solution for your laboratory or production needs.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Vacuum Dental Porcelain Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer