In short, yes. By formal definition, brazing is a metal-joining process that takes place above 450°C (which is 842°F). A filler metal with a melting point lower than the adjoining base metals is heated above its melting point and distributed between the closely fitted surfaces by capillary action. This specific temperature is the globally recognized line that separates brazing from the lower-temperature process of soldering.

The critical takeaway is not the exact number, but what it represents. The 450°C (842°F) threshold distinguishes high-strength brazing alloys from lower-strength solders, fundamentally defining the joint's mechanical properties and potential applications.

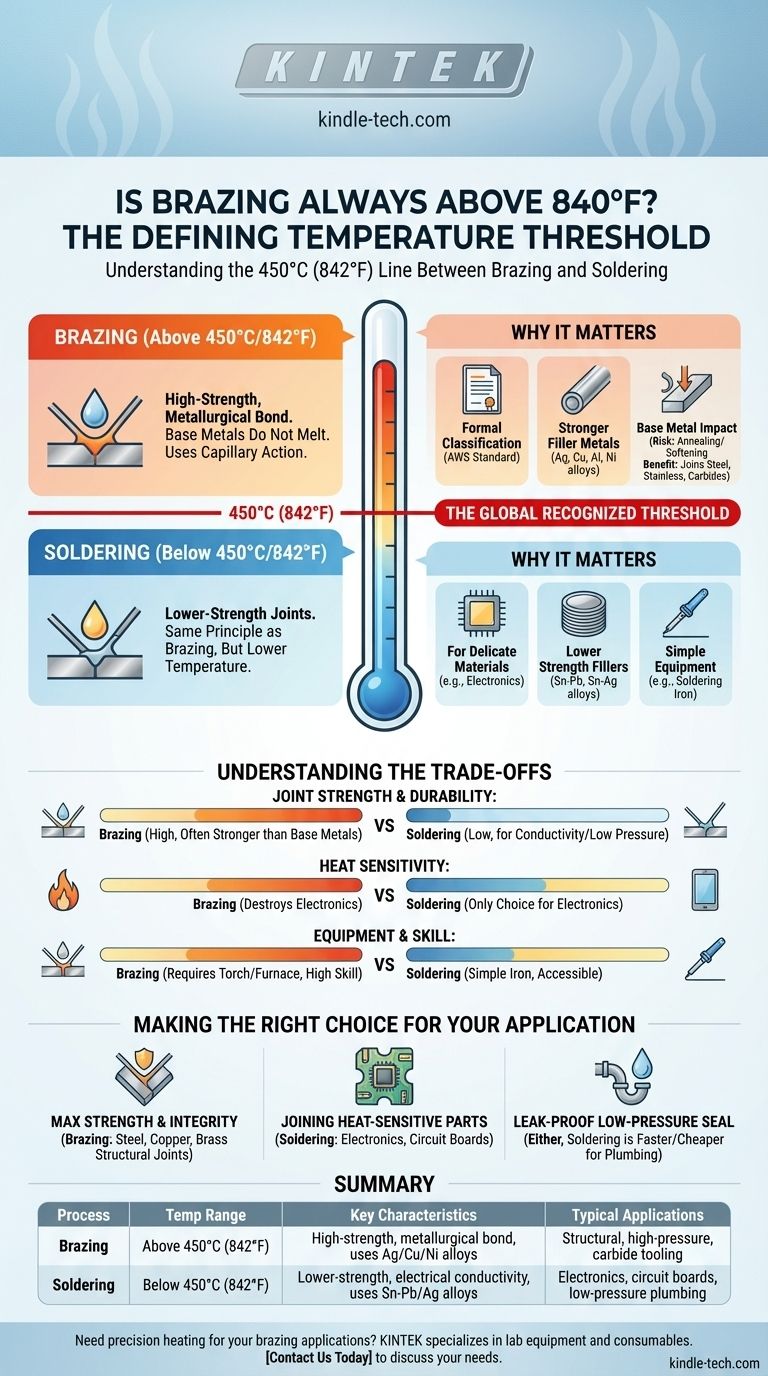

The Defining Line: Brazing vs. Soldering

To understand the importance of the temperature threshold, you must first understand the core mechanisms of brazing and its closest relative, soldering.

What is Brazing?

Brazing creates a metallurgical bond by heating two or more base metals and introducing a filler metal into the joint.

The filler metal has a lower melting point than the base metals. Crucially, the base metals themselves do not melt.

This process takes place at temperatures above 450°C (842°F).

What is Soldering?

Soldering follows the exact same principle as brazing: a filler metal is melted to join base metals that remain solid.

The key difference is temperature. Soldering is performed at temperatures below 450°C (842°F).

The Critical Role of Capillary Action

Both processes rely entirely on capillary action. This is the physical force that pulls the liquid filler metal into the tight gap between the base metal parts, ensuring a complete, strong bond without external pressure.

Why Does the 450°C (842°F) Threshold Matter?

This specific temperature isn't arbitrary; it's a formal classification that has significant practical implications for the materials used and the resulting joint characteristics.

A Formal Classification

Organizations like the American Welding Society (AWS) established this threshold to create a clear, unambiguous standard. This ensures that engineers, technicians, and designers are all speaking the same language when specifying a joining process.

Impact on Filler Metals

The temperature directly dictates the type of filler metal that can be used.

Brazing filler metals (often alloys of silver, copper, aluminum, or nickel) require higher temperatures to melt but offer vastly superior strength, ductility, and temperature resistance.

Soldering fillers (typically tin-lead, tin-silver, or other tin alloys) melt at low temperatures, making them easy to work with but resulting in much lower mechanical strength.

Effect on Base Materials

The higher heat required for brazing can affect the base metals. This can be a risk or a benefit.

For example, the heat can cause annealing (softening) or alter a prior heat treatment. This must be accounted for in the design. Conversely, it allows for the joining of materials like steel, stainless steel, and carbides that cannot be soldered effectively.

Understanding the Trade-offs

Choosing between brazing and soldering is a decision based on clear engineering trade-offs, not just temperature.

Joint Strength and Durability

Brazing is the clear winner for any application requiring high strength. A properly designed brazed joint can often be stronger than the base metals it joins, making it suitable for structural, high-pressure, and high-vibration environments.

Soldered joints are much weaker and are primarily used for creating electrical conductivity or a low-pressure seal.

Heat Sensitivity

Soldering's low temperature is its greatest advantage when working with delicate or heat-sensitive materials. It is the only choice for joining electronic components to a printed circuit board.

Brazing would instantly destroy such components.

Equipment and Skill

Soldering is highly accessible, often requiring little more than a simple soldering iron.

Brazing requires a more powerful heat source, such as an oxy-acetylene torch or a furnace, and demands a higher level of skill to manage the heat and ensure proper filler flow.

Making the Right Choice for Your Application

Ultimately, the temperature is just a guide that points to the correct process for your goal.

- If your primary focus is maximum strength and structural integrity: Brazing is the superior choice for creating robust, load-bearing joints in materials like steel, copper, and brass.

- If your primary focus is joining heat-sensitive electronics or components: Soldering is the only viable option due to its low-temperature application.

- If your primary focus is creating a leak-proof seal in low-pressure plumbing: Either process can work, but soldering is often faster and more cost-effective for standard copper piping.

Understanding these fundamental differences allows you to move beyond a simple temperature rule and select the ideal joining method for your specific engineering goal.

Summary Table:

| Process | Temperature Range | Key Characteristics | Typical Applications |

|---|---|---|---|

| Brazing | Above 450°C (842°F) | High-strength joints, metallurgical bond, uses silver/copper/nickel alloys | Structural components, high-pressure systems, carbide tooling |

| Soldering | Below 450°C (842°F) | Lower-strength joints, electrical conductivity, uses tin-lead/silver alloys | Electronics, circuit boards, low-pressure plumbing |

Need precision heating for your brazing applications? KINTEK specializes in lab equipment and consumables, offering reliable furnaces and heating solutions tailored to your laboratory's metal-joining needs. Whether you're working with high-strength alloys or heat-sensitive materials, our expertise ensures optimal performance and durability. Contact us today to discuss how we can support your brazing and soldering processes!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Muffle Furnace Oven for Laboratory

- Large Vertical Graphite Vacuum Graphitization Furnace

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

People Also Ask

- What is the pressure on a tube furnace? Essential Safety Limits for Your Lab

- What are the benefits of a tube furnace? Achieve Superior Temperature & Atmosphere Control

- What tube is used for tubular furnace? Choose the Right Material for Temperature & Atmosphere

- How does a tube furnace work? Master Precise Thermal and Atmospheric Control

- What are the tubes in a furnace called? Understanding the Role of the Working Tube