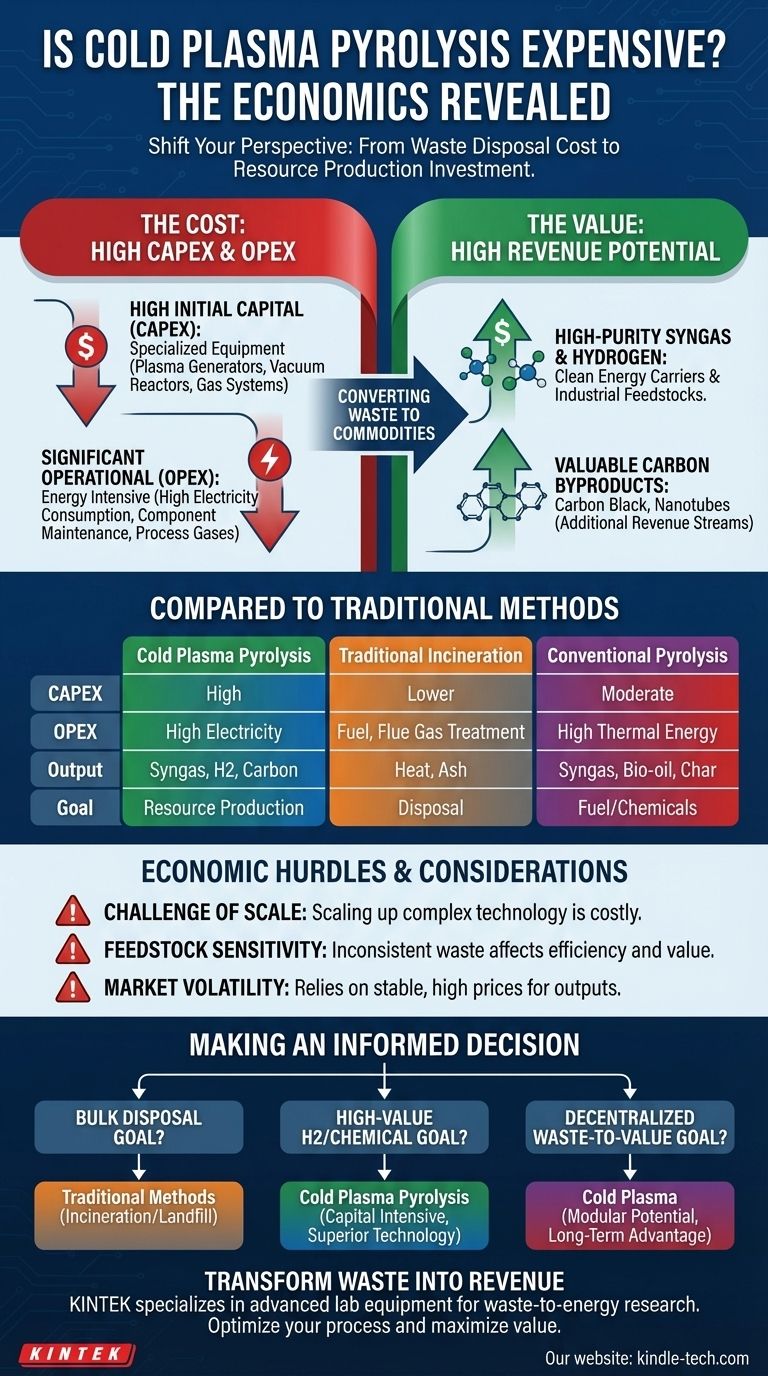

In short, yes. Cold plasma pyrolysis systems are generally more expensive to build and operate than conventional waste treatment technologies like incineration or landfilling. Their economic viability is not measured by disposal cost alone, but by their unique ability to convert waste into high-value commodities like hydrogen and syngas, creating a manufacturing process rather than just a disposal one.

The core issue is one of perspective. While the initial capital and operational costs are high, the technology's true economic potential is realized by shifting the goal from low-cost waste disposal to high-value resource production. The question is less about its expense and more about its long-term return on investment.

Deconstructing the Costs: CAPEX vs. OPEX

To understand the economics, we must separate the initial investment from the ongoing running costs. Cold plasma pyrolysis is demanding in both areas.

High Initial Capital Expenditure (CAPEX)

The upfront cost is driven by highly specialized equipment. This isn't a simple furnace; it's a sophisticated chemical reactor.

Key cost drivers include the plasma generation system (e.g., microwave generators, power supplies, waveguides), the low-pressure or vacuum reactor vessel, and the complex gas handling and product separation systems. These components require precision engineering and advanced materials.

Significant Operational Expenditure (OPEX)

The primary operational cost is electricity. Generating and sustaining a plasma is an energy-intensive process that consumes a significant amount of electrical power.

Other major operational costs include the maintenance of specialized components like electrodes and plasma sources, as well as the potential need for process gases like argon to initiate and stabilize the plasma.

How It Compares to Traditional Methods

The cost of cold plasma only makes sense when compared to the alternatives and their respective outputs.

vs. Incineration

Incineration plants typically have a lower initial CAPEX. However, they face increasingly strict environmental regulations regarding emissions (NOx, SOx, dioxins), requiring expensive flue gas treatment systems.

The primary output of incineration is heat (often for electricity) and ash, which requires further disposal. Cold plasma, by contrast, breaks materials down into valuable chemical building blocks.

vs. Conventional Pyrolysis

Conventional (thermal) pyrolysis uses external heat to break down materials in an oxygen-free environment. Its main cost is the thermal energy required to maintain very high temperatures (often >500°C).

Cold plasma uses targeted electrical energy to create highly reactive chemical species (ions, radicals) at a lower overall gas temperature. This allows for more precise control over the chemical reactions, often yielding a cleaner, more valuable syngas with less tar. The trade-off is higher electricity costs for higher product quality.

The "Revenue" Side of the Equation

The high cost of cold plasma pyrolysis is intended to be offset by the value of its products. This is its fundamental economic advantage.

High-Purity Syngas and Hydrogen

The primary output is often a clean synthesis gas (syngas), which is a mixture of hydrogen (H₂) and carbon monoxide (CO). This syngas can be used to synthesize fuels and chemicals or be further processed to produce high-purity hydrogen.

Hydrogen is a high-value energy carrier and industrial feedstock, and the ability to produce it from waste is a major driver for the technology.

Solid Carbon Byproducts

Depending on the feedstock, the process can also co-produce valuable solid carbon materials, such as carbon black, which is used in tires and pigments, or even higher-value carbon nanotubes.

Selling these byproducts creates an additional revenue stream that can significantly improve the overall economic case.

Understanding the Economic Hurdles

Despite its potential, the technology faces real-world economic challenges that are critical to understand.

The Challenge of Scale

Many cold plasma systems are still at the pilot or demonstration scale. Scaling this complex technology up to process thousands of tons of waste per day presents significant engineering and financial challenges that have not yet been fully overcome.

Feedstock Sensitivity

The process efficiency and the quality of the end products can be highly sensitive to the composition of the incoming waste. Inconsistent or contaminated feedstock can disrupt operations and lower the value of the output, creating economic unpredictability.

Market Volatility

The economic model relies on stable, high prices for the produced hydrogen, syngas, or carbon. Fluctuations in these commodity markets can directly impact the profitability and payback period of a plant.

Making an Informed Decision

Your approach to cold plasma pyrolysis should be guided by your ultimate goal.

- If your primary focus is bulk waste disposal at the lowest possible cost: Traditional methods like strategically managed landfilling or large-scale incineration remain the most economical options today.

- If your primary focus is producing high-value hydrogen or chemical feedstocks from waste: Cold plasma pyrolysis is a capital-intensive but technologically superior pathway that warrants serious investigation.

- If your primary focus is decentralized "waste-to-value" conversion for specific, high-value waste streams: The modular potential of cold plasma systems could offer a compelling long-term advantage, justifying the higher initial investment.

Ultimately, evaluating cold plasma pyrolysis not as a disposal expense but as an investment in a resource production facility is the key to understanding its true cost.

Summary Table:

| Cost Factor | Cold Plasma Pyrolysis | Traditional Incineration |

|---|---|---|

| Initial CAPEX | High (specialized reactors, plasma systems) | Lower |

| Primary OPEX | High electricity consumption | Fuel costs, flue gas treatment |

| Primary Output | High-value syngas, hydrogen, carbon byproducts | Heat, electricity, ash for disposal |

| Economic Goal | Resource production and revenue generation | Low-cost waste disposal |

Ready to transform your waste stream into a revenue stream?

KINTEK specializes in advanced laboratory equipment and consumables for innovative waste-to-energy and pyrolysis research. Our expertise supports the development and scaling of technologies like cold plasma pyrolysis.

Whether you're a researcher, engineer, or project developer, we provide the high-quality tools and technical support you need to optimize your process and maximize the value of your outputs.

Contact our experts today to discuss how KINTEK can support your next-generation resource recovery project.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What is high temperature method? A Guide to Controlled Thermal Transformation

- What is the difference between RF and DC sputtering? Choose the Right Method for Your Material

- What is the temperature of sintering? A Guide to Optimizing Your Material's Properties

- What role does a constant temperature laboratory oven play in preparing waste eggshell catalysts? Ensure Peak Efficiency

- How does a constant temperature shaker contribute to the accuracy of antibiotic degradation? Precision Lab Results

- What is the function of a laboratory heater? Achieve Precise, Safe, and Controlled Heating

- What is the real life application of thin film interference? From Anti-Glare Glasses to High-Tech Semiconductors

- What are the advantages of RF sputtering over DC sputtering? Achieve Superior Thin Films for Advanced Applications