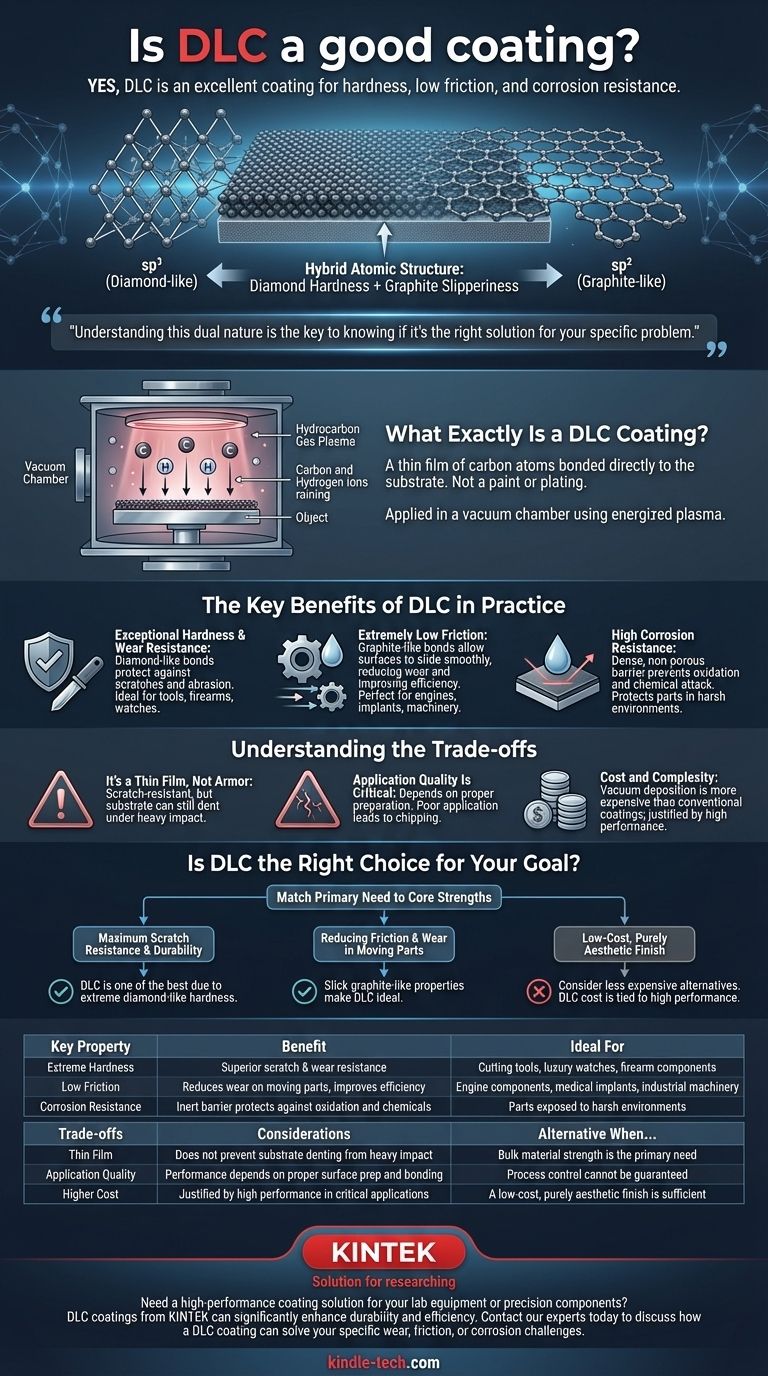

Yes, DLC is an excellent coating for applications where hardness, low friction, and corrosion resistance are critical. Its performance comes from a unique atomic structure that combines the properties of diamond and graphite into a single, thin layer.

The value of a Diamond-Like Carbon (DLC) coating isn't simply that it's "good," but that it offers a specific combination of diamond-like hardness and graphite-like slipperiness. Understanding this dual nature is the key to knowing if it's the right solution for your specific problem.

What Exactly Is a DLC Coating?

A DLC coating is a type of thin film applied to the surface of another material to enhance its properties. It is not a paint or a plating but a distinct layer of carbon atoms bonded directly to the substrate.

A Hybrid of Diamond and Graphite

The name "Diamond-Like Carbon" perfectly describes its structure. The coating is an amorphous film containing two types of carbon bonds: sp³ (diamond-like) and sp² (graphite-like).

This hybrid structure gives DLC its most important characteristics. The sp³ bonds provide extreme hardness and wear resistance, while the sp² bonds create a naturally slick, low-friction surface.

How The Coating Is Applied

The application process typically involves placing the object in a vacuum chamber. A hydrocarbon gas is introduced and energized into a plasma.

This plasma "rains" carbon and hydrogen ions onto the object's surface. These ions then recombine to form the dense, hard, and smooth DLC coating.

The Key Benefits of DLC in Practice

The unique atomic structure of DLC translates into three primary real-world advantages that make it a superior choice for high-performance applications.

Exceptional Hardness and Wear Resistance

Thanks to its diamond-like bonds, DLC is exceptionally hard and resistant to scratching and abrasion. This makes it ideal for protecting surfaces that experience constant contact or are exposed to harsh environments, such as cutting tools, firearm components, and luxury watches.

Extremely Low Friction

The graphite-like bonds give DLC a very low coefficient of friction, meaning surfaces can slide against each other with minimal resistance. This property is crucial for moving parts in engines, medical implants, and industrial machinery, where it reduces wear and improves efficiency.

High Corrosion Resistance

The dense, non-porous nature of a properly applied DLC coating creates an inert barrier between the underlying material and the environment. This effectively protects the substrate from oxidation and chemical corrosion.

Understanding the Trade-offs

While highly effective, DLC is a specialized coating, and it's important to understand its limitations to determine if it's the right choice.

It's a Thin Film, Not Armor

DLC coatings are extremely thin, often measured in microns. While the coating itself is incredibly scratch-resistant, it does not prevent the underlying material from denting under a heavy impact. A hard shell on a soft substrate can still be damaged.

Application Quality Is Critical

The performance of DLC is heavily dependent on the quality of the application process. Proper surface preparation and bonding are essential. A poorly applied coating can be prone to chipping or flaking, completely negating its benefits.

Cost and Complexity

The vacuum deposition process required for DLC is more complex and costly than conventional coatings like paint, powder coating, or even certain types of plating. Its use is typically reserved for applications where its high performance justifies the investment.

Is DLC the Right Choice for Your Goal?

To make the right decision, match your primary need to the core strengths of the coating.

- If your primary focus is maximum scratch resistance and surface durability: DLC is one of the best choices available due to its extreme, diamond-like hardness.

- If your primary focus is reducing friction and wear between moving parts: The slick, graphite-like properties of DLC make it an ideal solution for improving efficiency and longevity.

- If your primary focus is a low-cost, purely aesthetic finish: You may find that other, less expensive coatings can meet your needs, as the cost of DLC is tied directly to its high-performance characteristics.

By understanding its unique blend of properties, you can confidently decide if DLC is the high-performance solution your project requires.

Summary Table:

| Key Property | Benefit | Ideal For |

|---|---|---|

| Extreme Hardness | Superior scratch & wear resistance | Cutting tools, luxury watches, firearm components |

| Low Friction | Reduces wear on moving parts, improves efficiency | Engine components, medical implants, industrial machinery |

| Corrosion Resistance | Inert barrier protects against oxidation and chemicals | Parts exposed to harsh environments |

| Trade-offs | Considerations | Alternative When... |

| Thin Film | Does not prevent substrate denting from heavy impact | Bulk material strength is the primary need |

| Application Quality | Performance depends on proper surface prep and bonding | Process control cannot be guaranteed |

| Higher Cost | Justified by high performance in critical applications | A low-cost, purely aesthetic finish is sufficient |

Need a high-performance coating solution for your lab equipment or precision components?

DLC coatings from KINTEK can significantly enhance the durability and efficiency of your tools and instruments. Our expertise in lab equipment and consumables ensures a high-quality application that maximizes the benefits of DLC's unique properties.

Contact our experts today to discuss how a DLC coating can solve your specific wear, friction, or corrosion challenges.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- CVD Diamond Cutting Tool Blanks for Precision Machining

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Rotating Platinum Disk Electrode for Electrochemical Applications

People Also Ask

- What is the PECVD method? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are plasma deposition processes? Achieve High-Performance Thin Films at Lower Temperatures

- What are the components of PECVD? A Guide to Low-Temperature Thin Film Deposition Systems

- How does RF frequency in PECVD influence silicon nitride microstructure? Optimize Your Film Density & Stress

- What is Plasma-enhanced CVD (PECVD)? The Critical Benefits for CMOS Fabrication and Thin Film Quality

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition

- What is PECVD cluster tool deposition used for? Essential for High-Purity Multi-Layer Device Fabrication