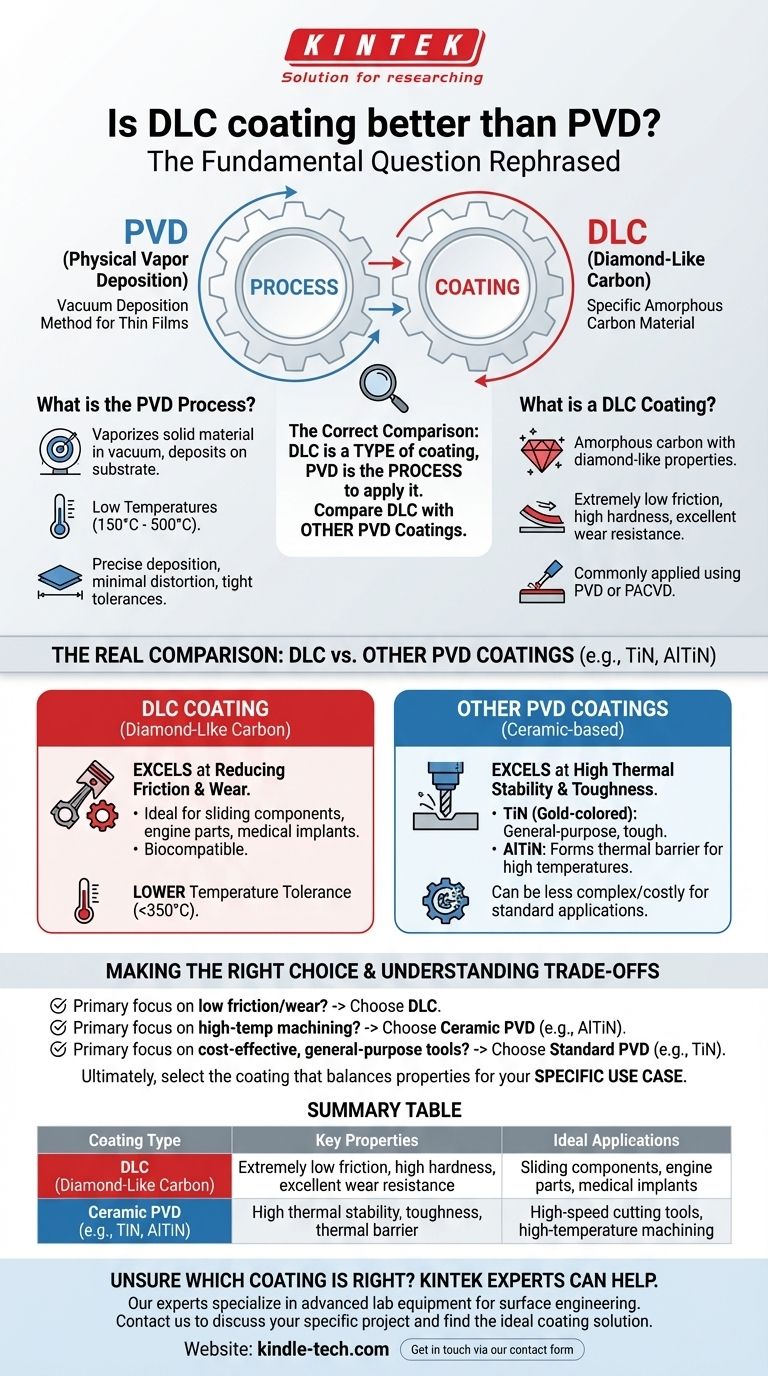

The fundamental question isn't whether DLC is better than PVD, because this comparison is based on a common misunderstanding. Diamond-Like Carbon (DLC) is a specific type of coating material, while Physical Vapor Deposition (PVD) is the process used to apply it. Therefore, DLC coatings are a subset of PVD coatings.

The correct question is not "DLC vs. PVD," but rather, "Is a DLC coating the right choice compared to other types of PVD coatings for my specific application?" Understanding this distinction is the key to making an informed decision.

What is the PVD Process?

Physical Vapor Deposition (PVD) is a family of vacuum deposition methods used to produce thin films and coatings. It is a process, not a single type of coating.

The Core Mechanism

The PVD process involves vaporizing a solid material in a vacuum environment and depositing it onto a target substrate. This is done at relatively low temperatures, typically between 150°C and 500°C.

Key Process Advantages

Because the process is computer-controlled and occurs in a vacuum, PVD offers significant benefits. It allows for the precise deposition of very thin films, often only a few microns thick.

The lower process temperatures mean there is little to no distortion of the underlying part, making it ideal for components with tight tolerances, such as cutting tools and precision machine parts.

What is a DLC Coating?

A Diamond-Like Carbon (DLC) coating is a specific material known for its unique properties. It is an amorphous carbon material that displays some of the desirable properties of natural diamond.

The Defining Properties

DLC coatings are prized for their extremely low coefficient of friction, high hardness, and excellent wear resistance. This combination makes them incredibly slick and durable.

How DLC is Applied

While other methods exist, DLC is most commonly applied using a PVD process or a closely related plasma-assisted chemical vapor deposition (PACVD) process. For the purposes of this comparison, it's critical to see DLC as one of the many high-performance materials that can be applied via PVD.

The Real Comparison: DLC vs. Other PVD Coatings

Now that we've established DLC is a type of PVD coating, the meaningful comparison is between DLC and other common PVD materials like Titanium Nitride (TiN) or Aluminum Titanium Nitride (AlTiN).

When DLC Excels

DLC is the superior choice when the primary goal is reducing friction. Its slick surface is ideal for sliding components, engine parts (like piston rings and wrist pins), and medical implants where low friction and biocompatibility are essential.

When Other PVD Coatings are Better

Ceramic-based PVD coatings like TiN, CrN, or AlTiN often have higher thermal stability than DLC. This makes them a better choice for high-speed cutting tools where extreme temperatures are generated at the cutting edge.

For example, gold-colored TiN is a tough, general-purpose workhorse coating. AlTiN forms a layer of aluminum oxide at high temperatures, creating a thermal barrier that protects the tool underneath.

Understanding the Trade-offs

Choosing a coating is never about finding one "best" option, but about balancing properties for a specific use case.

The Limits of DLC

While extremely hard and slick, most DLC coatings have a lower temperature tolerance compared to ceramic PVD coatings. They can begin to degrade at temperatures above 350°C, making them unsuitable for certain high-temperature applications.

The Importance of the Substrate

No coating can fix a poor substrate. The performance of any PVD coating, including DLC, is highly dependent on the hardness, finish, and preparation of the underlying material. A soft base material will not support a hard coating, leading to premature failure.

Cost and Complexity

DLC coatings can sometimes be more complex and costly to apply than standard TiN coatings. This cost must be justified by the significant performance gains in friction reduction and wear resistance.

Making the Right Choice for Your Goal

To select the correct coating, you must first define your primary performance objective.

- If your primary focus is reducing friction and wear in sliding components: DLC is almost certainly the superior PVD coating for your goal.

- If your primary focus is high-temperature machining performance: A ceramic PVD coating like AlTiN will likely outperform DLC.

- If your primary focus is a cost-effective, general-purpose hard coating for tools: A standard PVD coating like TiN is an excellent and proven starting point.

Ultimately, selecting the right surface treatment is about choosing the best tool for the job, not just the one with the most impressive name.

Summary Table:

| Coating Type | Key Properties | Ideal Applications |

|---|---|---|

| DLC (Diamond-Like Carbon) | Extremely low friction, high hardness, excellent wear resistance | Sliding components, engine parts, medical implants |

| Ceramic PVD (e.g., TiN, AlTiN) | High thermal stability, toughness, thermal barrier properties | High-speed cutting tools, high-temperature machining |

Unsure which coating is right for your components?

Choosing between DLC and other PVD coatings is critical for performance and longevity. KINTEK specializes in advanced lab equipment and consumables for surface engineering and analysis. Our experts can help you select and apply the ideal coating solution for your specific laboratory or manufacturing needs, ensuring optimal wear resistance, reduced friction, and enhanced component life.

Contact us today to discuss your project requirements and discover how our solutions can improve your results. Get in touch via our contact form.

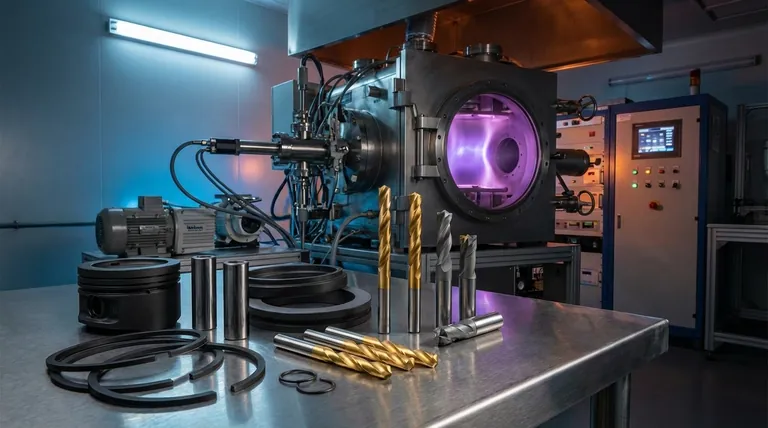

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- Is diamond coating worth it? Maximize Component Life and Performance

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools