The environmental friendliness of graphene production is a complex issue with no simple yes or no answer. The impact is not inherent to graphene itself, but is entirely dependent on the specific manufacturing method used. Some common, scalable methods rely on harsh chemicals and significant energy consumption, while newer, emerging techniques show promise for a much cleaner footprint.

The core issue is that the graphene industry has not yet standardized a single, scalable, and environmentally benign production method. Therefore, evaluating the environmental impact of graphene requires looking past the material and scrutinizing the specific process used to create it.

The Production Method Dictates the Impact

To understand the environmental cost, you must first understand the fundamental divide in how graphene is made. The two primary approaches, "top-down" and "bottom-up," come with vastly different environmental considerations.

The "Top-Down" Chemical Route

This approach starts with bulk graphite and exfoliates it down into single layers. The most common industrial method is a chemical process known as the Hummers' method.

This process involves using powerful oxidizing agents and strong acids (like sulfuric and nitric acid) to separate the graphite layers. This creates significant challenges, including the generation of toxic wastewater and the need for extensive purification, which itself consumes energy and resources.

The "Bottom-Up" Deposition Route

This approach builds graphene atom-by-atom on a substrate. The benchmark for high-quality graphene is Chemical Vapor Deposition (CVD).

In CVD, a hydrocarbon gas (like methane) is heated to extreme temperatures, often around 1000°C. At this heat, the gas decomposes, and carbon atoms deposit onto a metal catalyst (like copper) to form a pristine graphene sheet. The primary environmental drawbacks here are the high energy consumption and the use of greenhouse gas precursors.

Emerging "Green" Alternatives

Recognizing these challenges, researchers are actively developing more sustainable methods. These include electrochemical exfoliation, which uses electricity and milder chemicals, and even processes that use bio-waste as a carbon source.

While promising, these methods are less mature and often struggle to produce graphene at the quality or scale required for many commercial applications, a challenge noted in most industry analyses.

Understanding the Trade-offs

Choosing a graphene source involves navigating a complex landscape of cost, quality, and environmental impact. There is currently no perfect solution.

Purity vs. Environmental Cost

The highest-purity, defect-free graphene is typically produced via CVD. This quality is essential for advanced electronics but comes at a high energy cost. Conversely, the bulk graphene used for composites is often made via chemical exfoliation, which is cheaper but carries a heavy burden of chemical waste.

The Challenge of Scale

A process that seems clean in a laboratory setting can become an environmental problem when scaled up for mass production. The sheer volume of raw materials, energy inputs, and waste outputs is amplified, making efficient and clean processing paramount. The current lack of scalable and clean techniques is a primary bottleneck for the industry.

The Full Lifecycle Perspective

It's also crucial to consider the potential for graphene to create a net environmental benefit. Its use in creating stronger, lighter materials can reduce fuel consumption in vehicles. Its application in advanced batteries could be critical for the transition to renewable energy. These downstream benefits may ultimately outweigh the initial production impact.

How to Evaluate Graphene's Environmental Claims

When assessing graphene for your project, your primary task is to investigate the supplier's production method. Treat claims of "green graphene" with healthy skepticism and ask for specifics.

- If your primary focus is high-performance electronics: Inquire about the energy source and efficiency of the CVD process your supplier uses.

- If your primary focus is bulk industrial use (e.g., composites): Demand information on the chemical waste streams and water treatment processes associated with their exfoliation method.

- If your primary focus is sustainability: Look for suppliers pioneering newer methods like electrochemical exfoliation, but be prepared to rigorously test the material's quality and consistency.

By focusing on the production method rather than the material itself, you can make an informed and responsible decision.

Summary Table:

| Production Method | Key Environmental Impact | Typical Use Case |

|---|---|---|

| Chemical Exfoliation (e.g., Hummers' Method) | Toxic wastewater, harsh chemicals | Bulk composites, industrial materials |

| Chemical Vapor Deposition (CVD) | High energy consumption, greenhouse gases | High-performance electronics |

| Emerging Green Methods (e.g., Electrochemical) | Lower chemical/energy use (but less mature) | Sustainable applications (R&D focus) |

Choosing the right lab equipment is critical for developing sustainable materials like graphene. KINTEK specializes in providing the precise, reliable lab equipment and consumables needed for materials research and development. Whether you are optimizing a CVD process for high-quality graphene or exploring new, eco-friendly synthesis methods, our expertise can help you achieve your research goals efficiently and safely. Contact us today to discuss how we can support your laboratory's specific needs and contribute to your next breakthrough. Get in touch with our experts

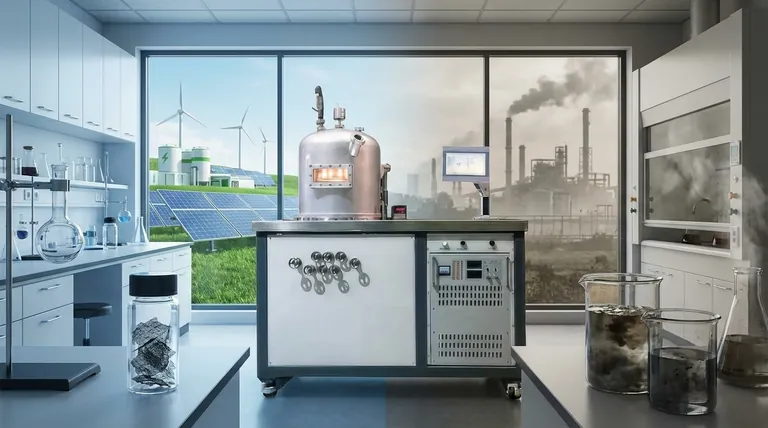

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance