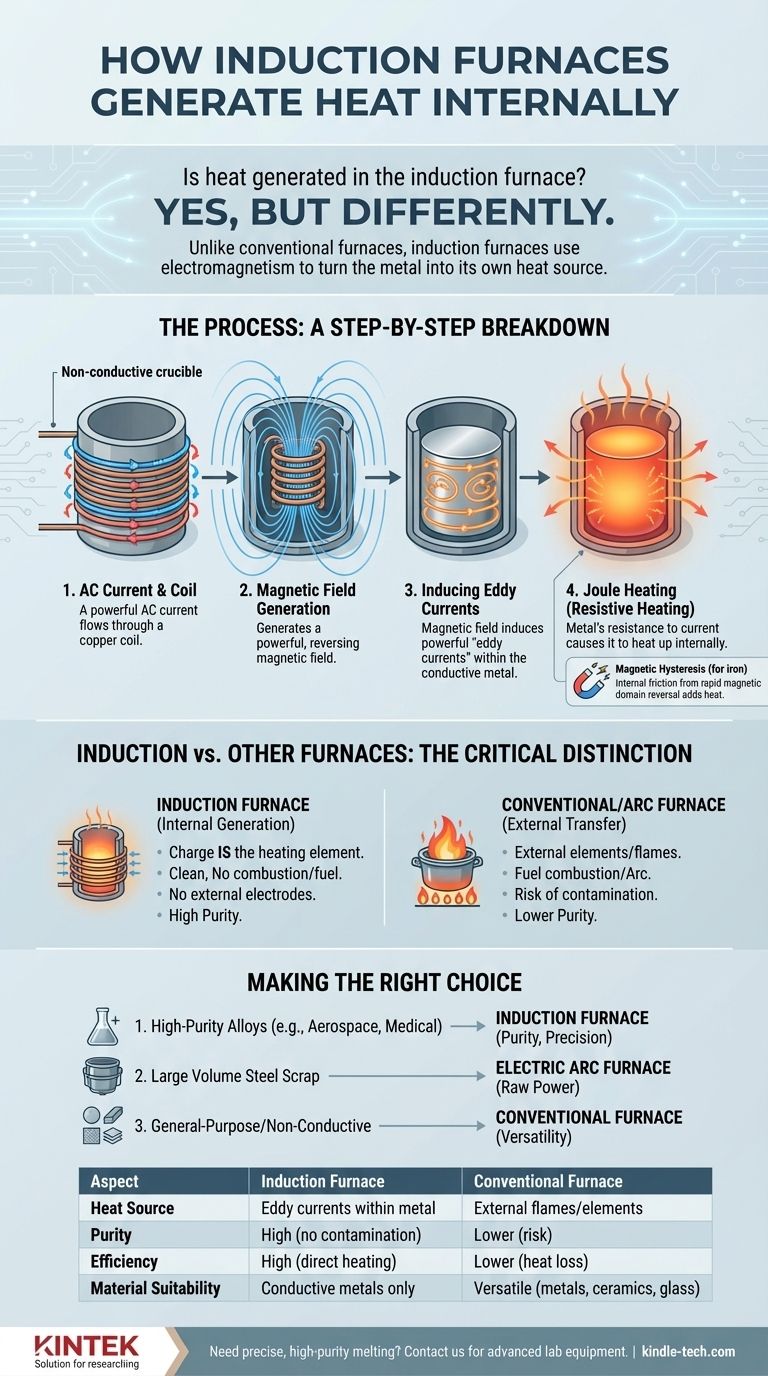

Yes, but not in the way you might think. The defining characteristic of an induction furnace is that the heat is generated directly within the metal charge itself. Unlike a conventional furnace that uses flames or glowing-hot elements to transfer heat to the metal, an induction furnace uses electromagnetism to turn the metal into its own heat source.

The core principle of an induction furnace is not heat transfer, but heat generation. It uses a powerful, changing magnetic field to induce electrical currents inside the metal, causing the metal to heat up from within. This method is fundamentally different from fuel-based or resistance-based furnaces.

How Induction Heating Works: A Step-by-Step Breakdown

To understand an induction furnace, you must first understand the physics of electromagnetic induction. The process is clean, contained, and highly efficient because it generates heat precisely where it is needed.

The Coil and the Current

An induction furnace is built around a non-conductive crucible, which holds the metal. This crucible is encircled by a coil of copper wire. A powerful alternating current (AC) is passed through this coil.

Generating the Magnetic Field

As the AC electricity flows, it generates a powerful and rapidly reversing magnetic field both inside and outside the coil. Because the crucible is non-conductive, this magnetic field passes through it unimpeded and penetrates the metal charge held within.

Inducing Eddy Currents

This rapidly changing magnetic field, in turn, induces powerful electrical currents within the conductive metal charge. These internal, circular currents are known as eddy currents.

The Principle of Joule Heating

The metal has natural electrical resistance. As these strong eddy currents flow through the resistive metal, they dissipate energy in the form of heat. This phenomenon, known as Joule heating (or resistive heating), is the primary source of heat in an induction furnace. The metal effectively heats itself from the inside out.

An Added Effect: Magnetic Hysteresis

For ferromagnetic materials like iron, there is a secondary source of heat. The rapid reversals of the magnetic field cause the magnetic domains within the iron to rapidly flip their alignment. This internal friction, called magnetic hysteresis, generates additional heat and contributes to the melting process.

The Critical Distinction: Induction vs. Other Furnaces

The "internal generation" method makes induction furnaces unique. Understanding the alternatives clarifies its specific advantages.

No External Heating Elements

Conventional electric furnaces use resistive heating elements made of materials like nickel-chrome alloy. These elements get extremely hot and radiate heat, which is then absorbed by the furnace contents. An induction furnace has no such heating element; the charge is the heating element.

No Combustion or Flames

Gas-fired furnaces generate heat by burning a fuel-air mixture. This process of combustion introduces byproducts and impurities into the heating environment. Induction furnaces use only electricity and magnetism, resulting in an exceptionally clean melt with no contamination from fuel.

No Electric Arc

An electric arc furnace, common in steelmaking, passes a massive current through a graphite electrode to create an arc to the metal scrap. This arc generates intense heat. Again, this is an external heat source, and the electrode can introduce carbon into the melt, which is not always desirable.

Understanding the Trade-offs

While powerful, the induction method is not a universal solution. Its unique principle comes with specific advantages and limitations.

Advantage: Purity and Precision

Because heat is generated internally and there is no combustion or contact with heating electrodes, an induction furnace offers unparalleled purity. This is critical for producing high-quality alloys in aerospace, medical, and electronics applications where even minor impurities are unacceptable.

Advantage: Efficiency and Speed

Heat is generated directly in the material, minimizing the energy wasted heating the furnace structure itself. This leads to very high thermal efficiency and rapid melting times compared to furnaces that rely on radiation and convection.

Limitation: Material Suitability

The process relies on the material being electrically conductive to support eddy currents. While excellent for metals like iron, steel, copper, and aluminum, it is ineffective for melting non-conductive materials like glass or ceramics.

Limitation: Equipment Complexity

Induction furnaces require a sophisticated and reliable high-frequency AC power supply and precisely engineered coils. This can lead to a higher initial investment and more complex maintenance compared to simpler fuel-fired furnace designs.

Making the Right Choice for Your Goal

The decision to use an induction furnace depends entirely on the metallurgical objective.

- If your primary focus is high-purity metal alloys: The induction furnace is the superior choice, as it prevents contamination from fuel, byproducts, or electrodes.

- If your primary focus is melting large volumes of steel scrap: An electric arc furnace is often the industry standard due to its raw power and effectiveness.

- If your primary focus is general-purpose heating or melting non-conductive materials: A conventional fuel-fired or electric resistance furnace offers greater versatility.

By understanding that an induction furnace turns the metal into its own heat source, you can select the right tool for the specific task at hand.

Summary Table:

| Aspect | Induction Furnace | Conventional Furnace |

|---|---|---|

| Heat Source | Eddy currents within the metal | External flames or heating elements |

| Purity | High (no contamination from fuel/electrodes) | Lower (risk of contamination) |

| Efficiency | High (direct internal heating) | Lower (heat loss to surroundings) |

| Material Suitability | Electrically conductive metals only | Versatile (metals, ceramics, glass) |

Need precise, high-purity metal melting solutions? KINTEK specializes in advanced lab equipment, including induction furnaces, to meet your specific metallurgical goals. Our expertise ensures you get the right equipment for efficient, contamination-free results. Contact us today to discuss how we can support your laboratory's needs!

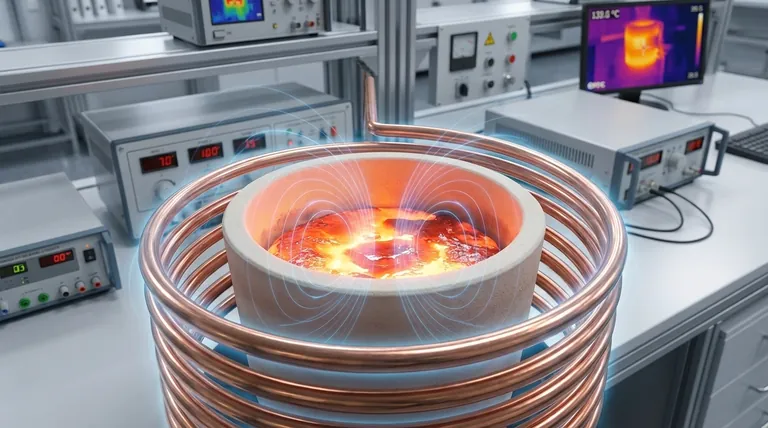

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- What are the benefits of a tube furnace? Achieve Superior Temperature & Atmosphere Control

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis