Yes, Hot Isostatic Pressing (HIP) is considered an expensive process. The cost stems from the highly specialized equipment required to create an environment of extreme temperature and uniform high pressure, as well as the operational resources needed to run the process safely and effectively.

While HIP involves a significant financial investment, its true value lies in achieving a level of material integrity and performance that is often unattainable through other methods. The decision to use it is less about minimizing cost and more about maximizing reliability for critical applications.

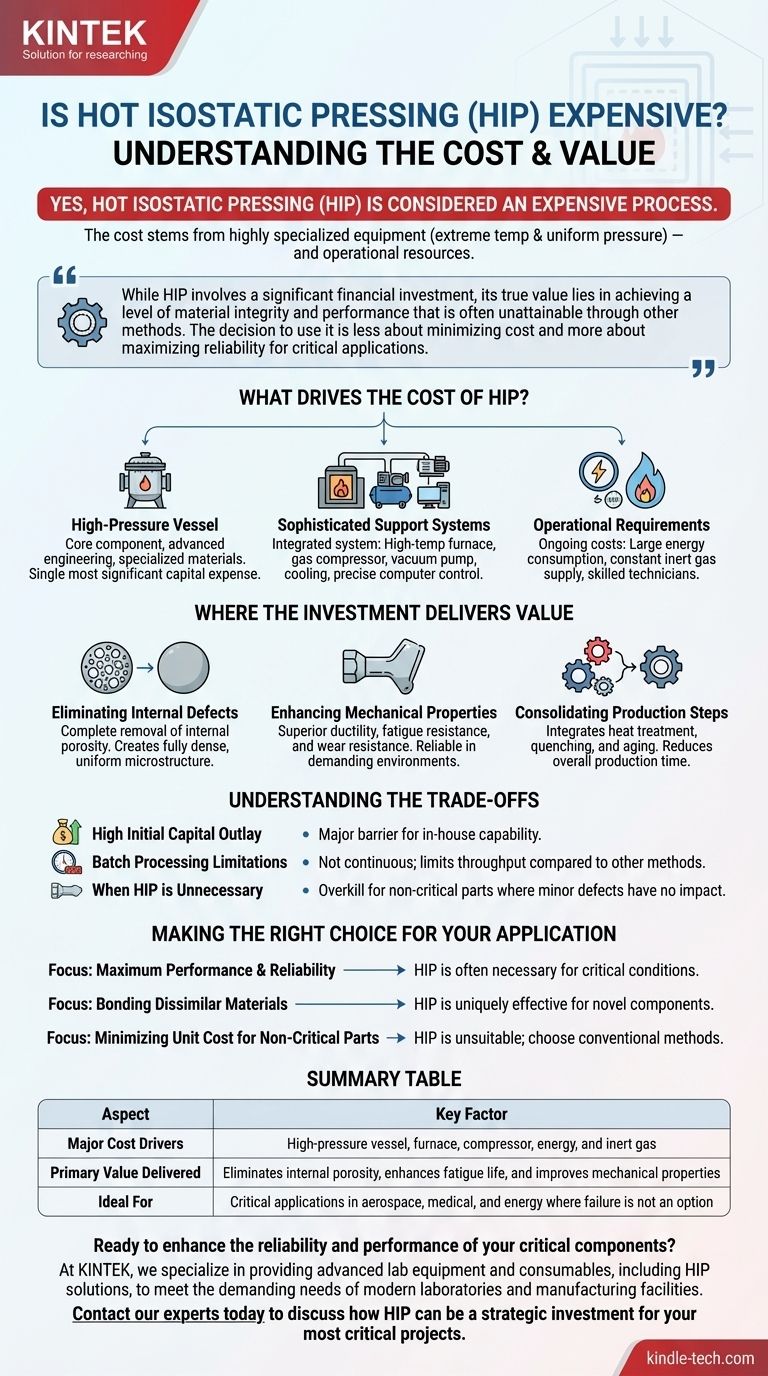

What Drives the Cost of HIP?

The high cost of Hot Isostatic Pressing is not arbitrary; it is a direct result of the complex and robust technology required to perform the process. Several key components contribute to the overall expense.

The High-Pressure Vessel

The core of any HIP system is the high-pressure vessel. This component must safely contain inert gas, like argon, at immense pressures while simultaneously enduring high temperatures. This requires advanced engineering and specialized materials, making it the single most significant capital expense.

Sophisticated Support Systems

A HIP unit is more than just a pressure chamber. It is an integrated system that includes a high-temperature furnace, a gas compressor, a vacuum pump, a cooling system, and a sophisticated computer control system to manage the entire cycle precisely. Each of these is a substantial piece of industrial equipment.

Operational Requirements

Beyond the initial equipment purchase, ongoing operational costs are also significant. The process consumes large amounts of energy to generate heat and pressure. It also requires a constant supply of inert gas and skilled technicians to operate and maintain the complex machinery.

Where the Investment Delivers Value

Despite the cost, HIP is widely used in critical industries because it delivers improvements that justify the expense. The value is measured in performance, reliability, and extended part life.

Eliminating Internal Defects

The primary benefit of HIP is the complete removal of internal porosity in castings, sintered parts, and additively manufactured components. The uniform pressure collapses internal voids, creating a fully dense, uniform microstructure that dramatically reduces the chance of internal failure points.

Enhancing Mechanical Properties

By creating a fully dense material, HIP significantly improves key properties. Parts exhibit superior ductility, fatigue resistance, and wear resistance. This allows components to perform reliably in demanding and high-stress environments where failure is not an option.

Consolidating Production Steps

Modern HIP systems can integrate processes like heat treatment, quenching, and aging into a single cycle. This consolidation can reduce overall production time and handling, offsetting some of the initial cost by streamlining the manufacturing workflow.

Understanding the Trade-offs

Choosing a manufacturing process always involves balancing cost against capability. HIP is a powerful tool, but it's essential to understand its specific trade-offs.

High Initial Capital Outlay

For companies looking to bring the capability in-house, the initial purchase price of a HIP system represents a major capital investment. This is often the largest barrier to adoption.

Batch Processing Limitations

HIP is a batch process, not a continuous one. Parts are loaded, the chamber is sealed, the cycle is run, and then the parts are unloaded. This can limit throughput compared to other, more continuous manufacturing methods.

When HIP is Unnecessary

For components where internal porosity or minor defects have no meaningful impact on performance, HIP is overkill. The significant cost is not justifiable for non-critical parts where standard casting or sintering methods are sufficient.

Making the Right Choice for Your Application

The decision to use HIP should be driven by the end-use requirements of the component.

- If your primary focus is maximum performance and reliability: HIP is often a necessary investment to eliminate internal defects and ensure parts can withstand extreme operational conditions.

- If your primary focus is creating parts from dissimilar materials: HIP is a uniquely effective method for bonding different materials together to create novel components with combined properties.

- If your primary focus is minimizing unit cost for non-critical parts: The high cost of HIP makes it unsuitable; more conventional and less expensive manufacturing methods are the logical choice.

Ultimately, viewing HIP as an investment in material integrity, rather than simply as a process cost, is the key to making an informed decision.

Summary Table:

| Aspect | Key Factor |

|---|---|

| Major Cost Drivers | High-pressure vessel, furnace, compressor, energy, and inert gas |

| Primary Value Delivered | Eliminates internal porosity, enhances fatigue life, and improves mechanical properties |

| Ideal For | Critical applications in aerospace, medical, and energy where failure is not an option |

Ready to enhance the reliability and performance of your critical components?

The significant investment in Hot Isostatic Pressing (HIP) is justified by the unparalleled material integrity it delivers. For high-stakes applications in aerospace, medical implants, and energy, HIP eliminates internal defects that can lead to catastrophic failures.

At KINTEK, we specialize in providing advanced lab equipment and consumables, including HIP solutions, to meet the demanding needs of modern laboratories and manufacturing facilities. Our expertise ensures you get the right technology to achieve full density and superior part performance.

Contact our experts today to discuss how HIP can be a strategic investment for your most critical projects.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the historical background of the Hot Isostatic Pressing (HIP) process? From Nuclear Roots to Industry Standard

- Is hot isostatic pressing a heat treatment? A Guide to Its Unique Thermomechanical Process

- What pressure is hot isostatic press? Achieve Full Density & Superior Material Performance

- What is HIP treatment for metal? Eliminate Internal Defects for Superior Part Performance

- What is the HIP material process? Achieve Near-Perfect Density and Reliability