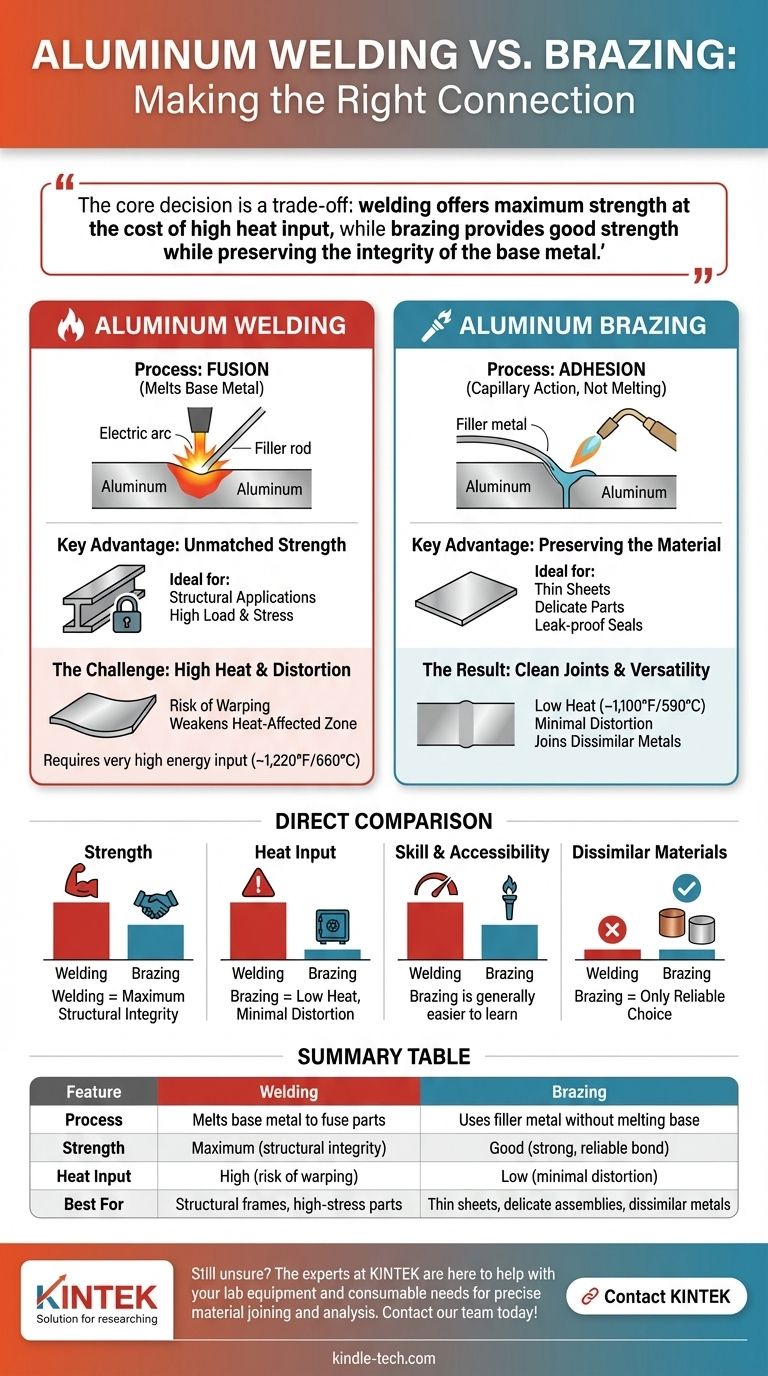

Choosing between welding and brazing aluminum requires understanding a fundamental difference in how they work. Neither process is universally "better." Welding creates the strongest possible bond by melting the aluminum parts together, while brazing uses a lower temperature to flow a filler metal into the joint without melting the aluminum itself, which drastically reduces the risk of distortion.

The core decision is a trade-off: welding offers maximum strength at the cost of high heat input, while brazing provides good strength while preserving the integrity of the base metal. Your specific application and material thickness will determine the correct choice.

What is Aluminum Welding?

Welding is a process of fusion. The goal is to make multiple pieces of aluminum behave as if they were one single, continuous piece.

The Principle: Fusing the Base Metal

Welding uses an intense heat source, such as an electric arc in TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding, to melt the edges of the aluminum parts being joined. A filler rod or wire of a compatible aluminum alloy is typically added to the molten puddle to build up the joint.

When this molten puddle cools and solidifies, the parent metal and the filler metal have fused into a single, homogenous piece of aluminum.

Key Advantage: Unmatched Strength

Because the joint becomes part of the base material, a properly executed weld is exceptionally strong. In many cases, the welded joint can be as strong, or even stronger, than the original aluminum it connects.

This makes welding the standard choice for structural applications where the joint must bear significant loads, stress, or vibration.

The Challenge: High Heat and Distortion

Aluminum has very high thermal conductivity, meaning heat dissipates through it rapidly. This requires a very high energy input to reach its melting point of around 1,220°F (660°C).

This intense, localized heat can easily cause thin sheets to warp or distort. It can also negatively affect the temper (heat-treated hardness) of the aluminum in the surrounding area, known as the heat-affected zone (HAZ), potentially weakening the material.

What is Aluminum Brazing?

Brazing is a process of adhesion and metallurgical bonding. It joins metals together without ever melting them.

The Principle: Capillary Action, Not Melting

In brazing, the aluminum parts are heated to a temperature that is above the melting point of the filler metal, but safely below the melting point of the aluminum itself.

Once the parts are hot enough, the brazing filler rod is touched to the joint. The molten filler is then pulled into the tight-fitting gap by a powerful phenomenon called capillary action. It forms a strong, permanent bond as it cools.

Key Advantage: Preserving the Material

The significantly lower temperatures used in brazing—typically around 1,100°F (590°C)—are its greatest asset. This gentle heating process all but eliminates the risk of warping and distortion.

Furthermore, it preserves the original temper and strength of the aluminum base metal, as the heat-affected zone is far less pronounced.

The Result: Clean Joints and Versatility

Brazing produces exceptionally clean, neat joints with smooth fillets that often require no further finishing.

Crucially, it is also highly effective for joining dissimilar metals, such as aluminum to copper or aluminum to steel, which is often impossible with welding.

Understanding the Trade-offs: A Direct Comparison

Your decision hinges on these key differences.

Strength and Durability

Welding is the clear winner for raw strength. If you are building a boat hull, a vehicle frame, or a structural support, welding is the appropriate choice. A brazed joint is strong, but it relies on the strength of the filler alloy, not a fusion of the parent metal.

Heat Input and Distortion

Brazing is vastly superior for controlling heat. If you are working with thin aluminum sheets, delicate components, or parts with tight tolerances (like in HVAC systems), brazing protects the assembly from heat-induced damage.

Skill and Accessibility

Brazing is generally considered easier to learn than TIG welding aluminum. Controlling a TIG arc on aluminum, cleaning the oxide layer, and managing the heat requires significant practice. Torch control for brazing is a more forgiving skill to acquire.

Joining Dissimilar Materials

Brazing is the only reliable choice for joining aluminum to most other metals. The fusion process of welding is incompatible with metals that have vastly different melting points and metallurgical properties.

Making the Right Choice for Your Application

Instead of asking which is "better," ask which is right for your goal.

- If your primary focus is maximum structural integrity: Choose welding (TIG for precision, MIG for speed) to create the strongest possible fused joint.

- If your primary focus is minimizing distortion on thin or delicate parts: Choose brazing to protect the base metal from the damaging effects of high heat.

- If your primary focus is creating a leak-proof seal in a complex assembly: Brazing provides excellent joint filling and clean fillets, ideal for tubing, tanks, or fluid systems.

- If your primary focus is joining aluminum to another metal: Brazing is the correct, and often only, viable method for the job.

By matching the process to the demands of the project, you ensure a successful and reliable outcome.

Summary Table:

| Feature | Welding | Brazing |

|---|---|---|

| Process | Melts base metal to fuse parts | Uses filler metal without melting base |

| Strength | Maximum (structural integrity) | Good (strong, reliable bond) |

| Heat Input | High (risk of warping) | Low (minimal distortion) |

| Best For | Structural frames, high-stress parts | Thin sheets, delicate assemblies, dissimilar metals |

Still unsure which process is right for your aluminum project? The experts at KINTEK are here to help. We specialize in providing the lab equipment and consumables needed for precise material joining and analysis. Whether you're working on structural components or delicate assemblies, we can guide you to the right solution. Contact our team today to discuss your specific application and ensure a successful outcome.

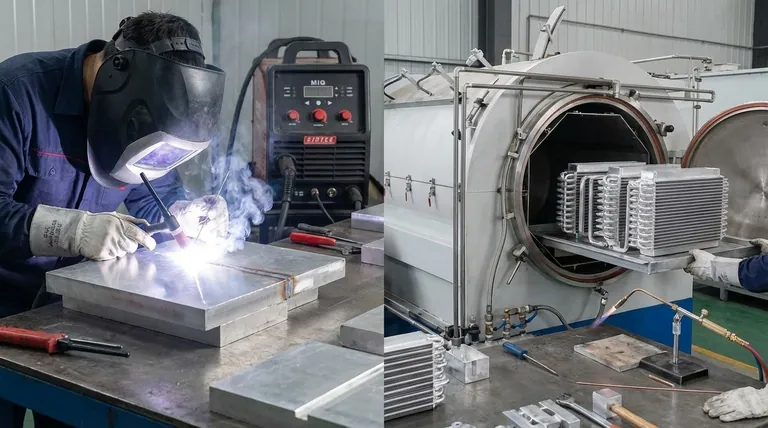

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are some applications of brazing? Join Dissimilar Metals with Strong, Leak-Proof Bonds

- What are the advantages of brazing over braze welding? Achieve Stronger, Cleaner, and Repeatable Joints

- Does brazing require heat? Yes, it's the catalyst for creating strong, permanent bonds.

- What is vacuum brazing? The Ultimate Guide to High-Purity, Flux-Free Metal Joining

- What is the basic of brazing? A Guide to Strong, Low-Heat Metal Joining