In short, yes, plastic pyrolysis can be harmful. While it presents a potential solution for plastic waste, the process itself can generate hazardous emissions, toxic byproducts, and contaminated residues. The level of harm is directly dependent on the type of plastic feedstock used, the sophistication of the technology, and the rigor of the environmental controls in place.

The core issue with plastic pyrolysis is not the intended chemical conversion, but the unintended and often unavoidable creation of harmful substances. The process breaks down complex plastics, but in doing so, it can release the very toxins and heavy metals the plastic contained, concentrating them into new, potentially hazardous products.

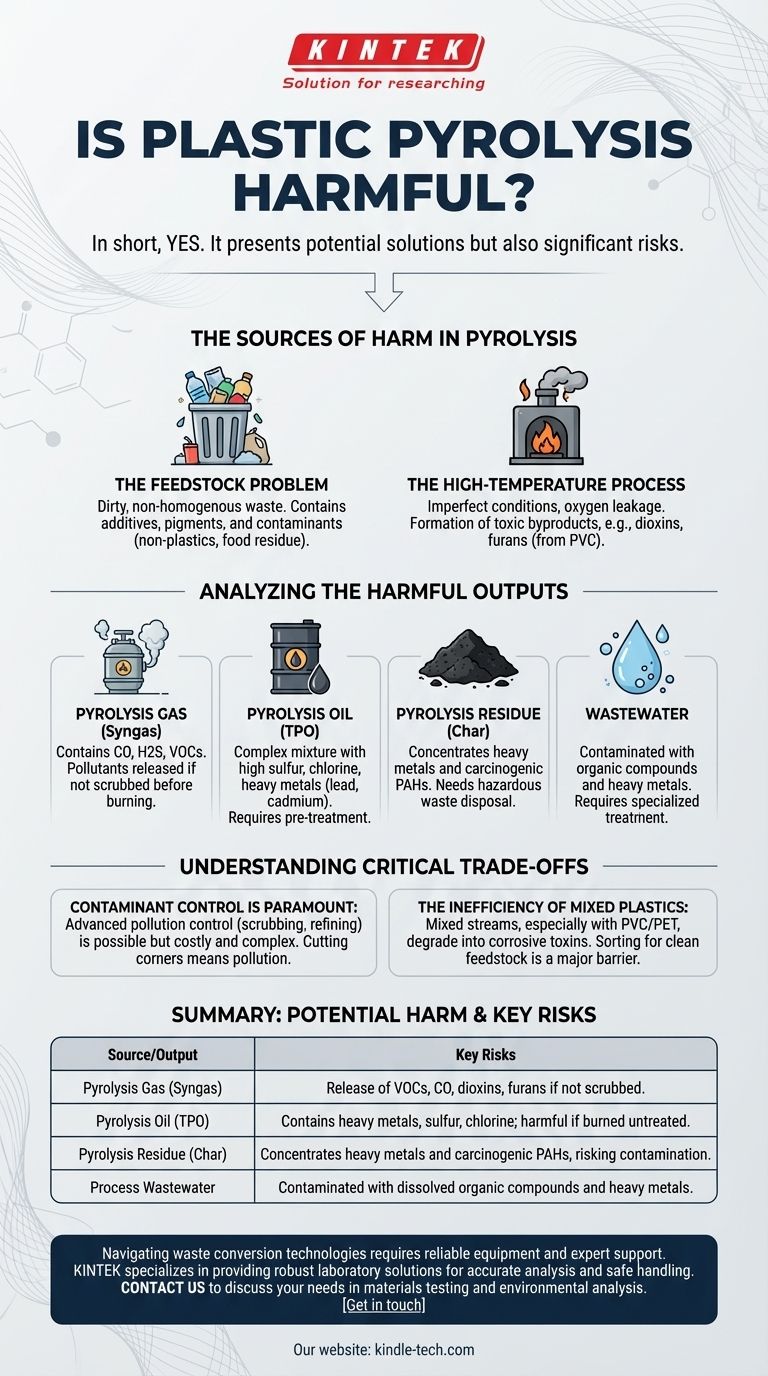

The Sources of Harm in Pyrolysis

To understand the risks, it's essential to see the pyrolysis system as a whole, with potential hazards arising from its inputs, its operational phase, and its outputs.

The Feedstock Problem

The primary input is plastic waste, which is rarely clean or homogenous. It often contains additives like pigments, flame retardants, and stabilizers.

Furthermore, waste streams are frequently contaminated with non-plastic materials, food residue, and other chemicals, all of which can complicate the process and create new toxic compounds.

The High-Temperature Process

Pyrolysis is the thermal decomposition of materials at elevated temperatures in the absence of oxygen. Imperfect process conditions, such as temperature fluctuations or the accidental introduction of oxygen, can lead to incomplete conversion.

This can result in the formation of highly toxic byproducts, including dioxins and furans, especially when chlorinated plastics like PVC are present in the feedstock.

Analyzing the Harmful Outputs

The reference correctly identifies the primary outputs: pyrolysis gas, oil, residue (char), and wastewater. Each carries a distinct risk profile.

Pyrolysis Gas (Syngas)

This gas mixture is often promoted as a fuel source. However, it can contain harmful components like carbon monoxide (CO), hydrogen sulfide (H2S), and various volatile organic compounds (VOCs).

If this gas is burned for energy without sufficient "gas cleaning" or scrubbing, these pollutants are released directly into the atmosphere, contributing to air pollution and health risks.

Pyrolysis Oil (TPO)

Often called "Tire-Derived Fuel Oil" or "Plastic-Derived Fuel Oil," this product is the main goal of most pyrolysis plants. Unfortunately, it is not equivalent to virgin diesel or crude oil.

It is often a complex, unstable mixture that contains high levels of sulfur, chlorine, and heavy metals (such as lead, cadmium, and chromium) that were originally in the plastic waste. Burning this oil as fuel without significant pre-treatment and refining can release these toxic substances.

Pyrolysis Residue (Char)

The solid, carbon-rich byproduct, known as char or "carbon black," is not inert. It acts like a sponge, concentrating the heavy metals and other contaminants from the original plastic feedstock.

This residue can also contain Polycyclic Aromatic Hydrocarbons (PAHs), many of which are carcinogenic. If not handled and disposed of as hazardous waste, these toxins can leach into soil and groundwater.

Wastewater

Any moisture in the plastic waste is converted to steam and then condensed into wastewater during the process. This water comes into contact with the various chemicals and can become contaminated with dissolved organic compounds and heavy metals, requiring specialized treatment before it can be safely discharged.

Understanding the Critical Trade-offs

Evaluating pyrolysis requires acknowledging the significant operational challenges that determine its true environmental impact.

Contaminant Control is Paramount

The single greatest factor determining if a pyrolysis plant is harmful is the quality of its pollution control systems. Effective scrubbing of gases, refining of oil, and management of toxic char are technologically possible but add significant cost and complexity.

Facilities that cut corners on these systems are not recycling facilities; they are sources of pollution.

The Inefficiency of Mixed Plastics

Most pyrolysis technologies struggle with mixed plastic waste, especially plastics containing chlorine (PVC) or PET. These materials degrade into highly corrosive and toxic substances that can damage equipment and produce extremely hazardous outputs.

Sorting plastic waste to create a clean, homogenous feedstock is a major logistical and economic barrier that is often underestimated.

Making an Informed Assessment

When evaluating a plastic pyrolysis proposal, your questions should focus on a verifiable, end-to-end management of all outputs.

- If your primary focus is environmental protection: Demand a full chemical analysis of the pyrolysis oil, char, and wastewater to verify contaminant levels, and require continuous emissions monitoring data from the facility's smokestack.

- If your primary focus is economic viability: Scrutinize the costs of feedstock sorting, advanced pollution control, hazardous waste disposal for the char, and the necessary upgrading of the pyrolysis oil to meet market fuel specifications.

Ultimately, the potential of plastic pyrolysis hinges entirely on managing the hazardous substances it inevitably handles and creates.

Summary Table:

| Potential Harm | Source/Output | Key Risks |

|---|---|---|

| Toxic Emissions | Pyrolysis Gas (Syngas) | Release of VOCs, carbon monoxide, dioxins, and furans if not properly scrubbed. |

| Contaminated Fuel | Pyrolysis Oil (TPO) | Contains heavy metals (lead, cadmium), sulfur, chlorine; harmful if burned untreated. |

| Hazardous Solid Waste | Pyrolysis Residue (Char) | Concentrates heavy metals and carcinogenic PAHs, risking soil/water contamination. |

| Polluted Water | Process Wastewater | Can be contaminated with dissolved organic compounds and heavy metals. |

Navigating the complexities of waste conversion technologies requires reliable equipment and expert support. KINTEK specializes in providing robust laboratory equipment and consumables to help you accurately analyze feedstock and monitor process outputs, ensuring safety and compliance. Whether you are researching, developing, or scaling a pyrolysis process, our solutions support precise control and hazardous material handling. Contact us today to discuss how we can support your laboratory's specific needs in materials testing and environmental analysis. Get in touch via our contact form

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success